Construction method for external heat preservation of concrete wall

A construction method and technology for concrete walls, applied in thermal insulation, building components, etc., can solve problems such as cracks in the cement mortar protective layer, achieve the effects of saving formwork usage, solving cracks in the protective layer, and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

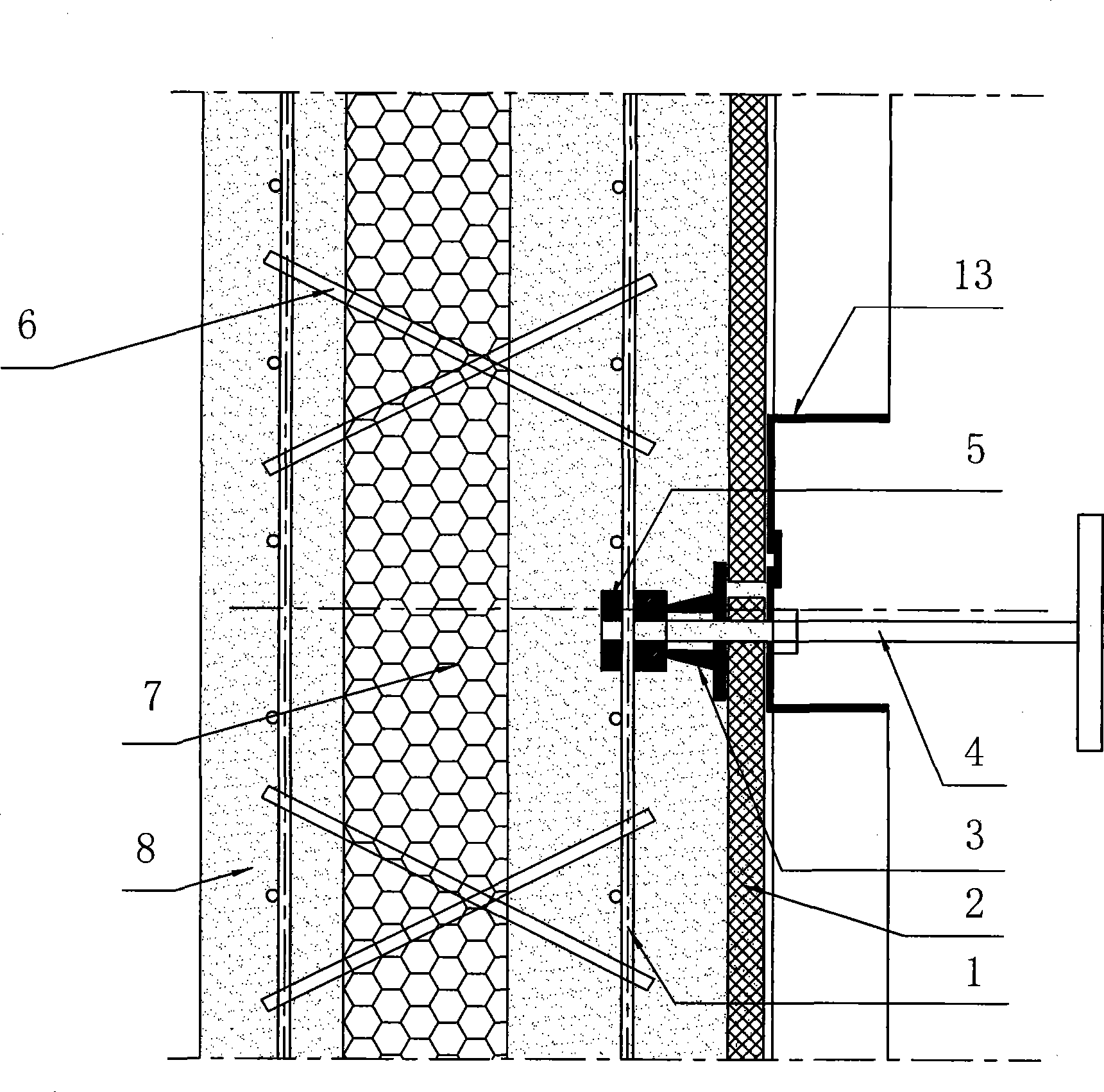

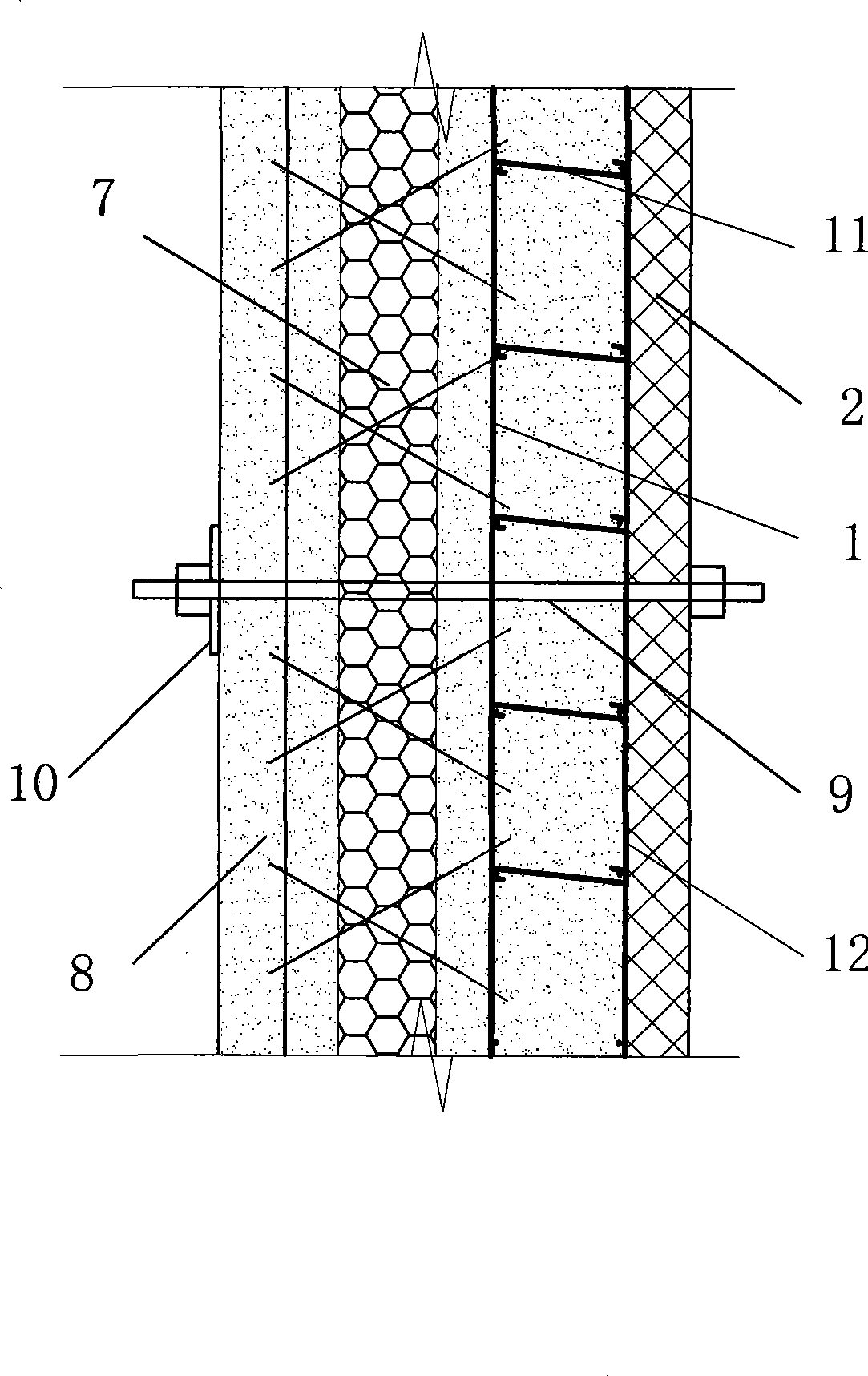

[0022] figure 1 , figure 2 , shown in the construction structure diagram of the concrete heat-insulating load-bearing wall, the construction method of the present invention is characterized in that the injection of concrete on the inner and outer walls is carried out step by step:

[0023] A. Prefabricated load-bearing slabs: Welding of eccentrically sandwiched steel cross-linked frame plates is completed on the steel cross-linked welding production line and delivered to the construction site. For details, see the prior patent of the applicant for this patent;

[0024] B. Assembling the load-bearing slab: After hoisting the eccentric sandwich steel cross-linked frame slab to the construction site, tie and connect the anchor bars, beams, and column steel bars reserved for the inner wall with the eccentric sandwich steel cross-linked frame slab anchor bars;

[0025] C. Spray concrete 3-5cm directly on one side of the eccentric sandwich steel cross-linked frame plate relying on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com