Amorphous particle reinforced magnesium-base composite material and manufacture process

A composite material and amorphous particle technology, applied in the field of metal matrix composite material and its preparation technology, can solve the problems of unsuitability for industrial production, poor wettability, poor bonding between reinforcement and matrix interface, etc. Reliability, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

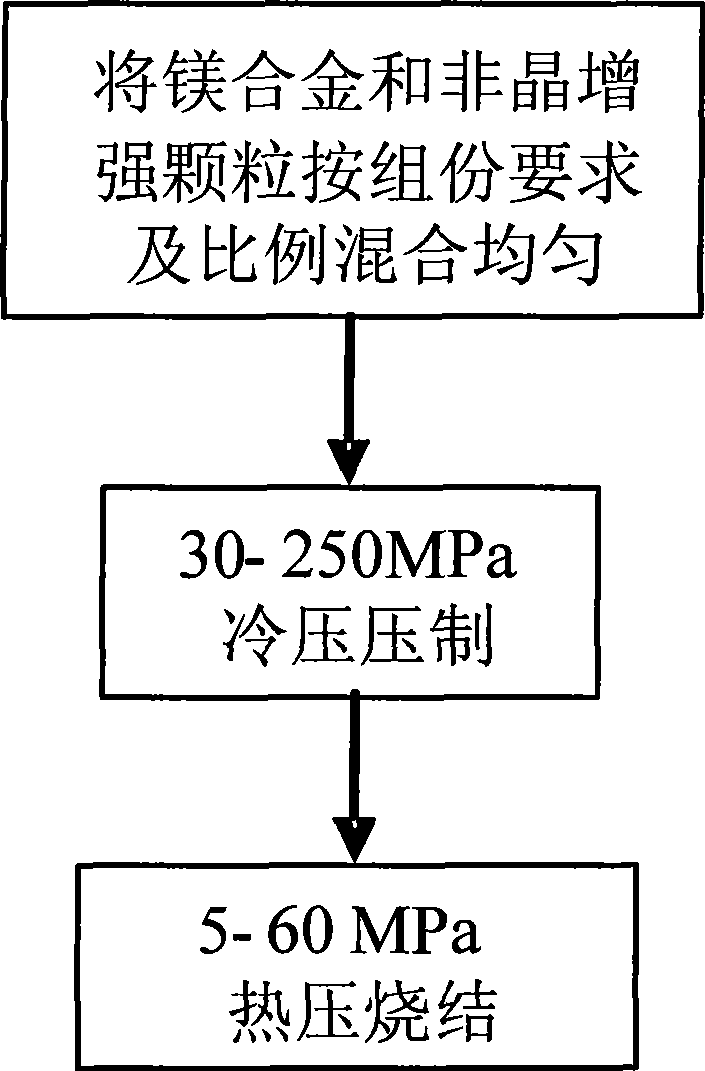

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0033] Provide the embodiment shown in table 1 according to above-mentioned matrix material, reinforcing body material and technical scheme:

[0034] Matrix composition (weight percent)

[0035] No.1 100% Mg

[0036] No.2 90% Mg, 9% Al, 0.2% Mn, 0.8% Zn

[0037] No.3 80% Mg, 15% Al, 1.6% Mn, 1.4% Zn, 1.0% Si, 0.5% Cu, 0.3% Ni, 0.2% Fe

[0038] No.4 81.9% Mg, 18% Al, 0.1% Mn

[0039] No.5 82% Mg, 13% Al, 0.5% Mn, 4.5% Zn

[0040] No.6 80% Mg, 14% Al, 1.6% Mn, 1.4% Zn, 0.5% Ce, 1.0% Zr, 1.3% B, 0.2% Gd

[0041] The particle sizes of the matrix materials are 400 μm, 300 μm, 200 μm, 250 μm, 300 μm, and 300 μm, respectively.

[0042] Reinforcement composition (atomic percent)

[0043] No.1 60% Ni, 40% Nb

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com