Inorganic putty powder with function of governing humidness

A technology of putty powder and interior wall putty powder, which is applied in the field of building decoration materials, can solve the problems of poor moisture absorption and desorption characteristics, limited moisture absorption and desorption, and direct use obstacles, and achieve the effect of excellent environmental protection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] Example 1: Mix the following components into putty powder:

[0034] White cement 15kg

[0035] Ash calcium powder 10kg

[0036] Heavy Calcium Powder 10kg

[0037] Talc powder 10kg

[0038] Gypsum powder 20kg

[0039] Latex powder DM200 4.5 kg

[0040] Methylcellulose 0.5 kg

[0041] Diatomaceous earth (after pretreatment) 30 kg

[0042] Mix the above components into 100 kg of putty powder. When used, it can be prepared according to the weight ratio of water: putty powder 0.4:1.

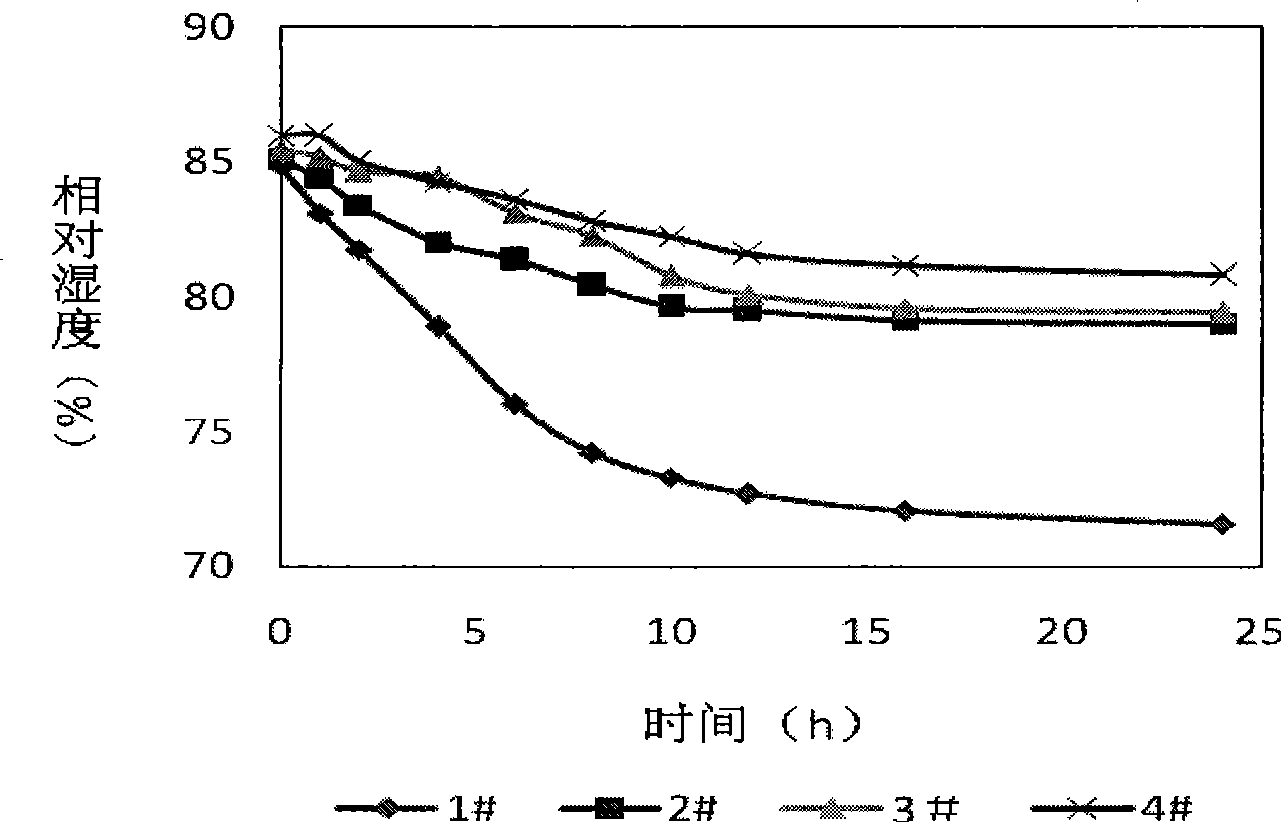

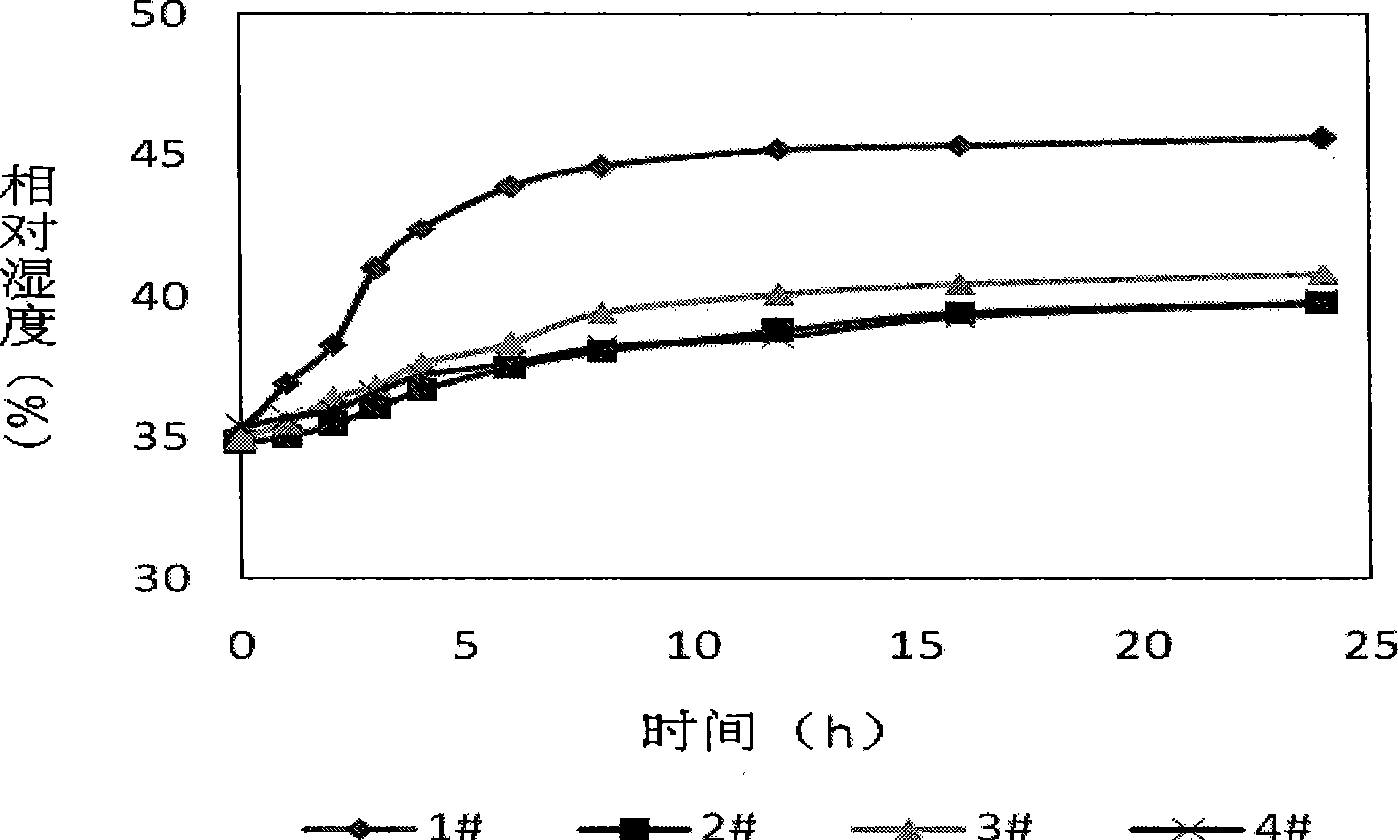

[0043] Test method: Take 200g of putty powder and divide it into two parts, stir it evenly with water, then scrape and coat it on a 150mm×1500mm glass plate, let it dry naturally, put it in an oven, and dry it at 80°C for 5 hours. Then put the two samples in a 10L airtight container with a temperature of 25°C and a relative humidity of 85%, and measure the maximum decrease in relative humidity in the container. After the relative humidity in the airtight container reaches equilibrium, c...

example 2

[0048] Example 2: Mix the following components into putty powder:

[0049] Ordinary Portland cement 33 kg

[0050] Heavy Calcium Powder 9kg

[0051] Talc powder 6 kg

[0052] Latex powder 2488 1.5 kg

[0053] Methylcellulose 0.5 kg

[0054] Attapulgite clay 25kg

[0055] Sepiolite (after pretreatment) 25 kg

[0056] 100 kilograms of putty powder are mixed by above-mentioned components. When in use, it can be formulated according to the weight ratio of water: putty powder 0.4:1.

[0057] Carry out functional test with the same method as Example 1, as a result, under the conditions of temperature 25°C and relative humidity 85%, the maximum reduction of relative humidity reaches 14%RH; Dehumidification under certain conditions, resulting in a maximum increase in relative humidity of 12% RH.

example 3

[0058] Example 3: Mix the following components into putty powder:

[0059] Ordinary Portland white cement 50kg

[0060] Double Fly Powder 14kg

[0061] Lithopone 10kg

[0062] Latex powder DP-88 0.5 kg

[0063] Methylcellulose 0.5 kg

[0064] Vermiculite powder (after pretreatment) 15 kg

[0065] Bentonite (after pretreatment) 10 kg

[0066] 100 kilograms of putty powder are mixed by above-mentioned components. When in use, it can be formulated according to the weight ratio of water: putty powder 0.4:1.

[0067] Carry out functional test with the same method as Example 1, the result is under the condition of temperature 25 ℃, relative humidity 85%, relative humidity maximum reduction amount reaches 10%RH; Dehumidification under certain conditions, resulting in a maximum increase in relative humidity of 7% RH.

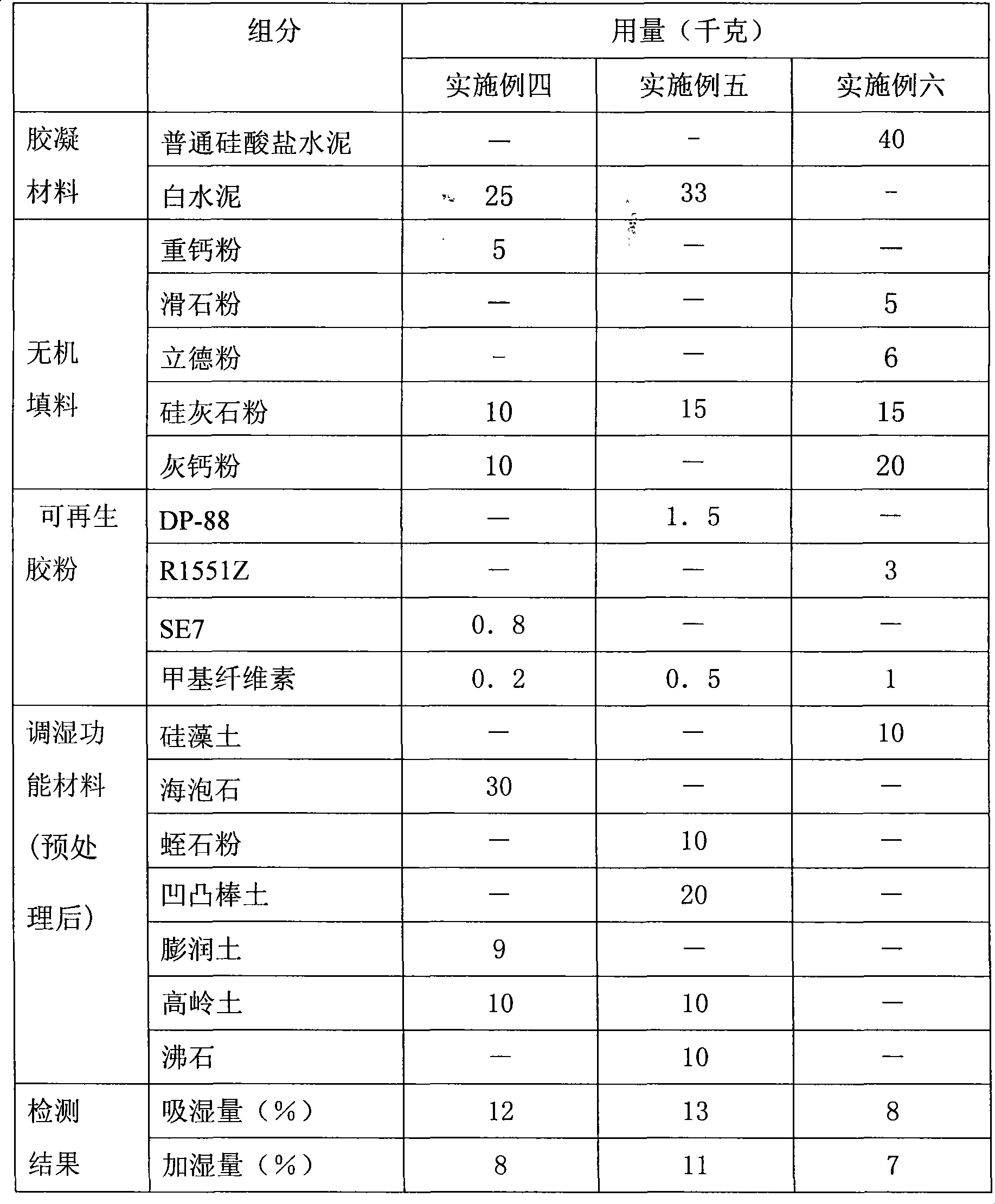

[0068] Embodiments 4-6: Mix the components and dosages in Table 1 to form a putty powder, and perform functional testing with the same method as in Embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com