Electrophotographic cleaning blade, process for producing electrophotographic cleaning blade, and electrophotographic apparatus

一种电子照相、清洁刮板的技术,应用在电记录术、光学、仪器等方向,能够解决未说明固化层硬度等问题,达到抑制刮板翘起、光滑性改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

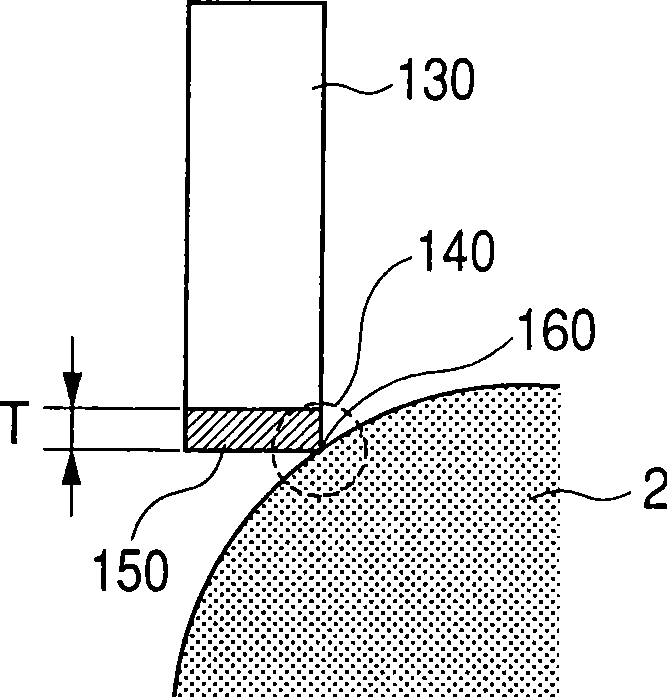

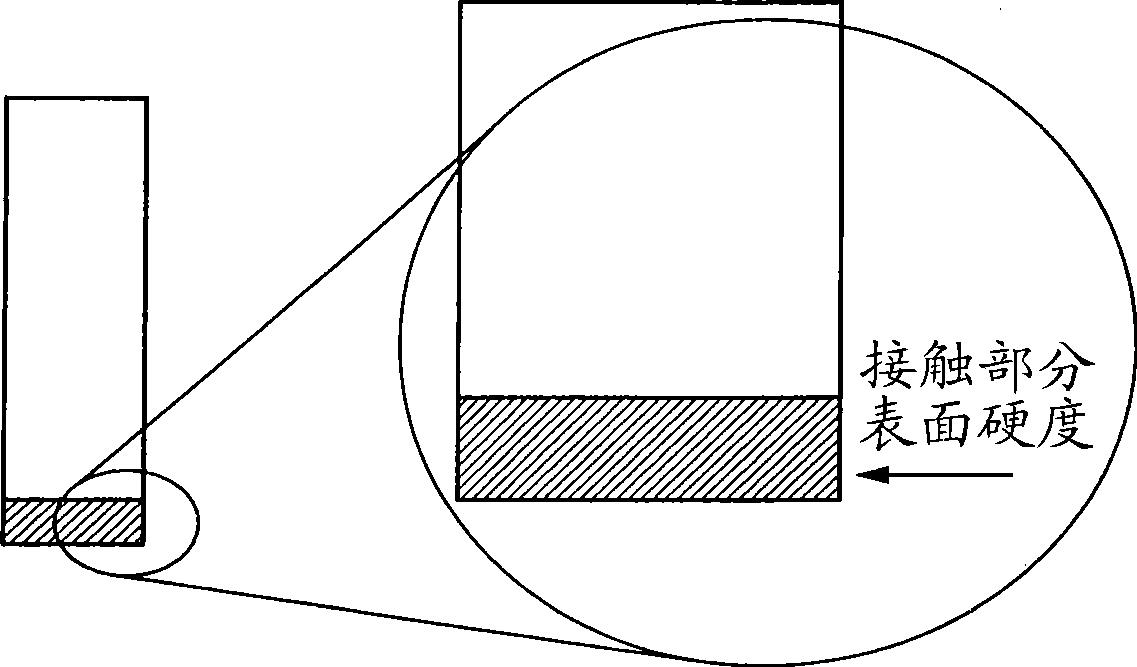

[0110] A prepolymer (NCO%: 7%) was prepared from a butylene / hexylene adipate type polyester polyol having a weight average molecular weight of 2000 and MDI. In this prepolymer, a mixed crosslinking agent of 1,4-butanediol and trimethylolpropane (mass ratio: 65:35) was mixed such that the hydroxyl group / NCO molar ratio was 0.95, thereby preparing a polyurethane raw material. Using this polyurethane raw material, a blade (IRHD: 75°) formed of a polyurethane resin having a thickness of 2 mm was produced by molding. The scraper was produced by molding using a centrifugal molding machine. In this molding, the raw material was cured under conditions of a curing temperature of 130° C. and a curing time of 30 minutes. The scraper is bonded to a plate metal to produce a cleaning scraper. In this case, the edge used to bond the scraper to the sheet metal was 5mm, and the scraper was cut so that its length along its free length was 10mm.

[0111] The cleaning blade obtained by prelimi...

Embodiment 2

[0114] A cleaning blade was produced in the same manner as in Example 1 except that the time during which the blade was kept in contact with the isocyanate compound MTL was changed to 100 minutes.

Embodiment 3

[0116] In addition to preparing the polyurethane raw material so as to have a hydroxyl group / NCO molar ratio of 0.80, changing the curing time to 20 minutes and changing the time to keep the blade in contact with the MTL to 5 minutes in molding using a centrifugal molding machine, the cleaning blade Plates were produced in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com