Cooling water jacket of petroleum coke can-type calcine furnace

A tank-type calciner and cooling water jacket technology, which is applied in coking ovens, petroleum industry, special forms of dry distillation, etc., can solve the problems of thermal deformation and low cost of heat conduction parts, achieve uniformity improvement, material temperature reduction, and reduce failures rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

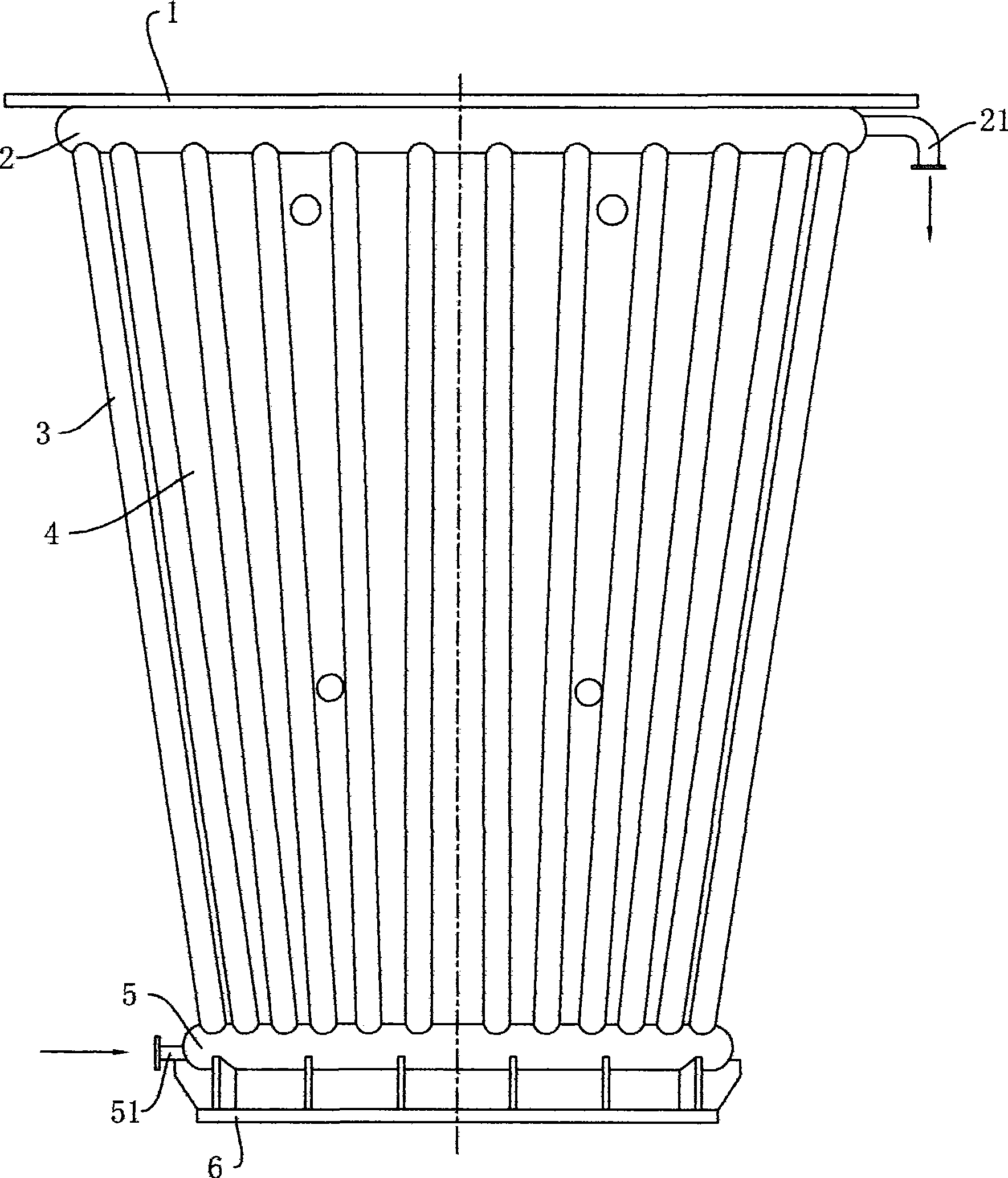

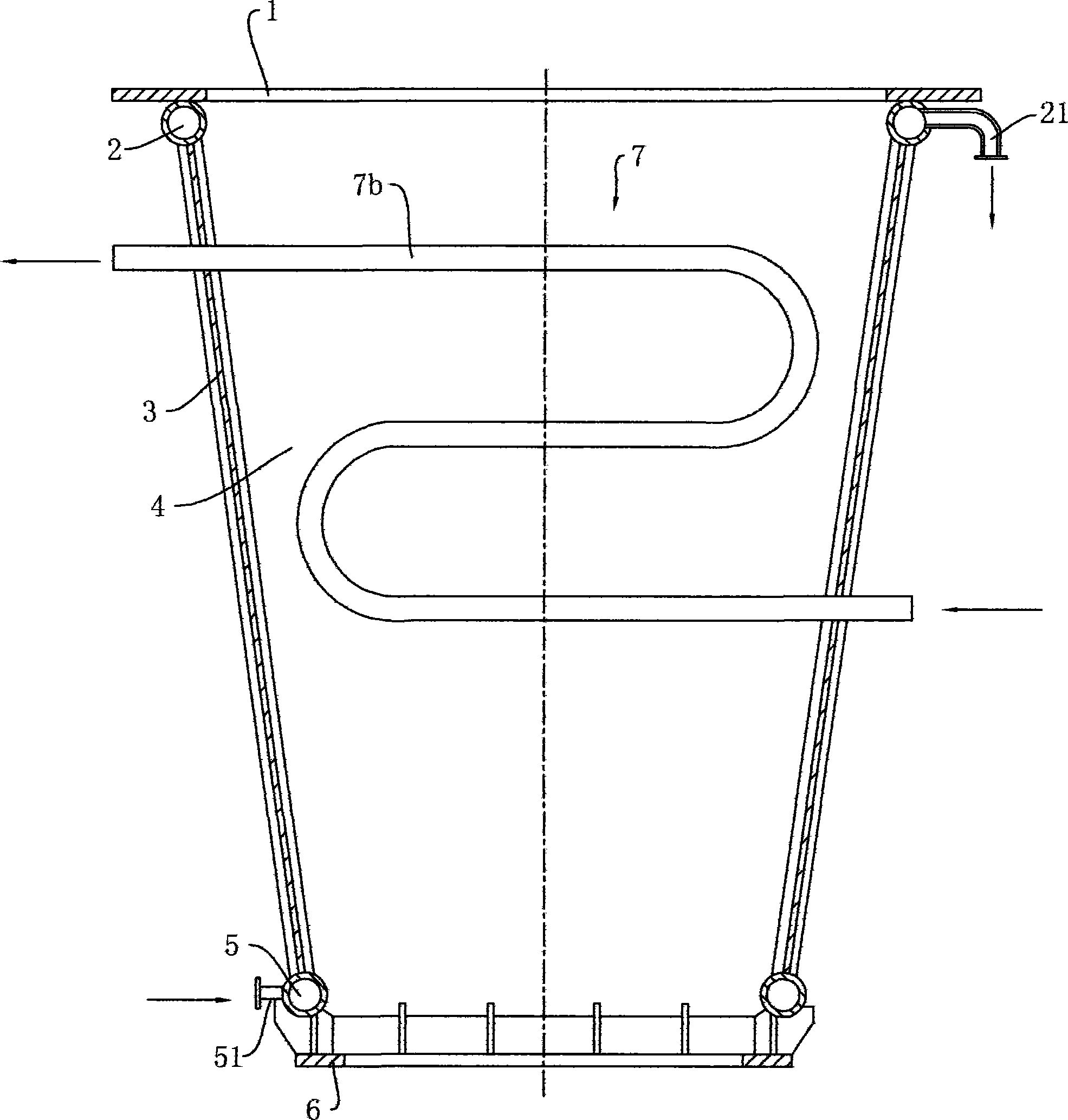

[0016] Such as figure 1 As shown, a petroleum coke tank type calciner cooling water jacket, which includes an annular upper header 2, the upper header is provided with a water outlet 21, and the upper flange 1 is welded to the upper header 2 On, the upper flange 1 is used to connect with the body of the calciner. It also includes an annular lower header 5, which is provided with a water inlet 51 and a sewage outlet (not shown in the figure), and the lower flange 6 is welded as a whole with the lower header 5 through a cylinder and Ribs are provided, and the lower flange 6 is used to connect with the discharge valve. The purpose of setting the cylinder body and the ribs is to facilitate the connection between the lower flange 6 and the discharge valve.

[0017] A plurality of heat exchange tubes 3 are respectively welded between the upper header 2 and the lower header 5, and the heat exchange tubes 3 communicate with the upper header 2 and the lower header 5 respectively to fo...

no. 2 example

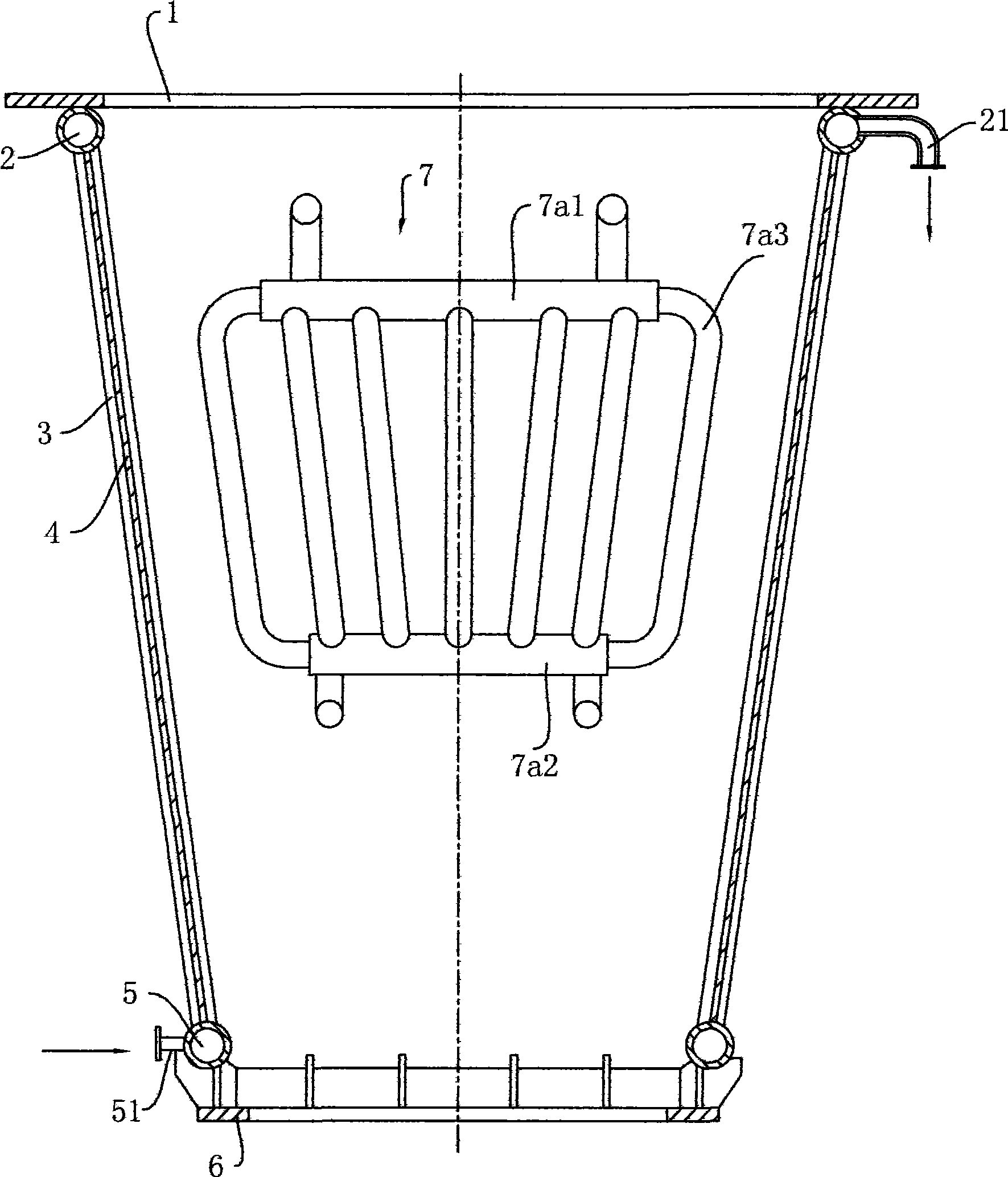

[0022] The structure of the second embodiment is basically the same as that of the first embodiment, the difference lies in the structure of the secondary heat exchange device 7, such as image 3 As shown, it includes an upper horizontal tube 7a1, a lower horizontal tube 7a2, and a plurality of vertical tubes 7a3 that are respectively fixedly connected and communicated with the upper horizontal tube 7a1 and the lower horizontal tube 7a2; A water outlet is provided, and a water inlet is provided on the lower horizontal pipe 7a2; the water outlet arranged on the upper horizontal pipe and the water inlet arranged on the lower horizontal pipe are respectively fixedly connected with a heat conduction baffle and extend out a high temperature outside of the material channel.

[0023] The present invention is not limited to the specific embodiments described above. An inventive point of the present invention is that the primary heat exchange device is welded into a whole by the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com