Front fork lining reaming machine

A reaming machine and bushing technology, which is applied in the direction of reaming devices, reaming devices, metal processing machinery parts, etc., can solve the problems of high cost and high equipment requirements, and achieve the effect of convenient operation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

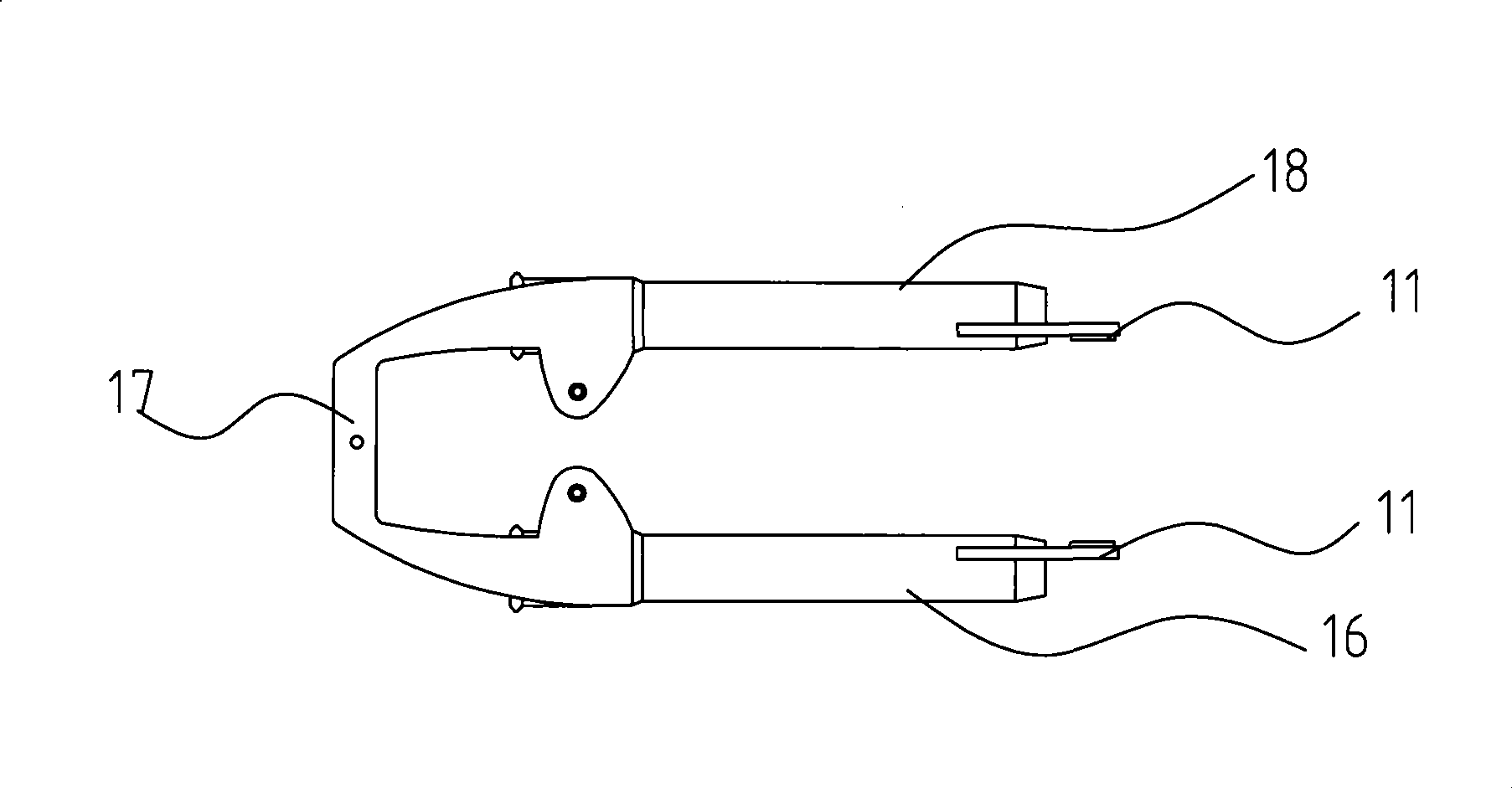

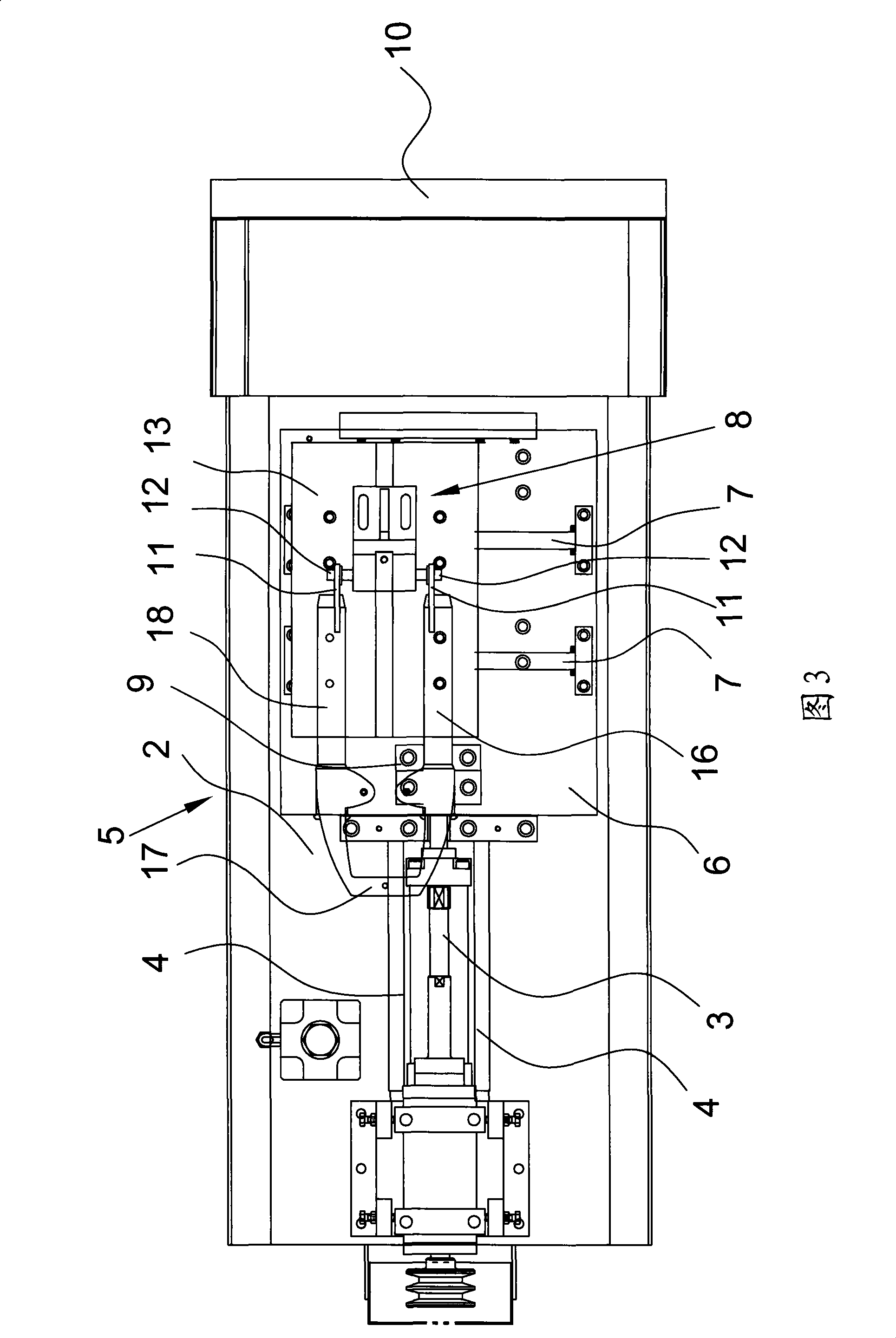

[0015] As shown in accompanying drawing 3 and accompanying drawing 4, a kind of front fork bush reaming machine, it comprises support 1, the workbench 2 that is arranged on described support 1, is rotatably arranged on described support 1 And the axis line is parallel to the tool 3 of the workbench 2, the first guide rail 4 fixedly arranged on the workbench 2, and the workpiece fixing mechanism 5 slidably arranged on the first guide rail 4 , the length direction of the first guide rail 4 is parallel to the axial direction of the tool 3, and the workpiece fixing mechanism 5 includes a fixing seat 6 slidably arranged on the first guide rail 4 , the second guide rail 7 fixedly arranged on the said fixing seat 6 , the claw fixing seat 8 slidably arranged on the said second guide rail 7 , the support member fixedly arranged on the said fixing seat 6 9. The extension direction of the second guide rail 7 is perpendicular to the extension direction of the first guide rail 4, and a gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com