Pentahedron gantry processing center double-exchange workpiece conveying platform

A processing center and conveying platform technology, applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of occupying space and long rail length, and achieve low cost of improvement, improve work efficiency, and ensure processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

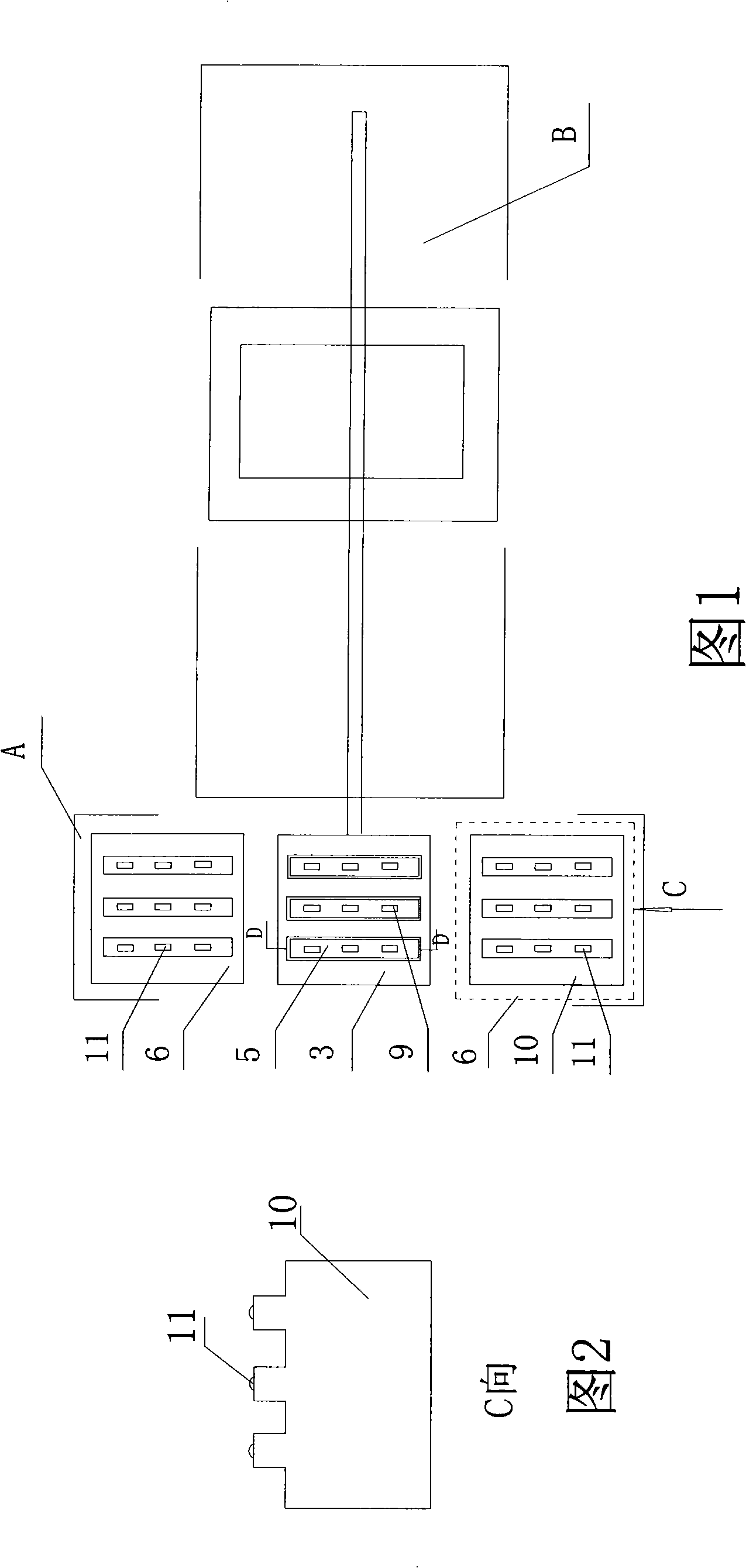

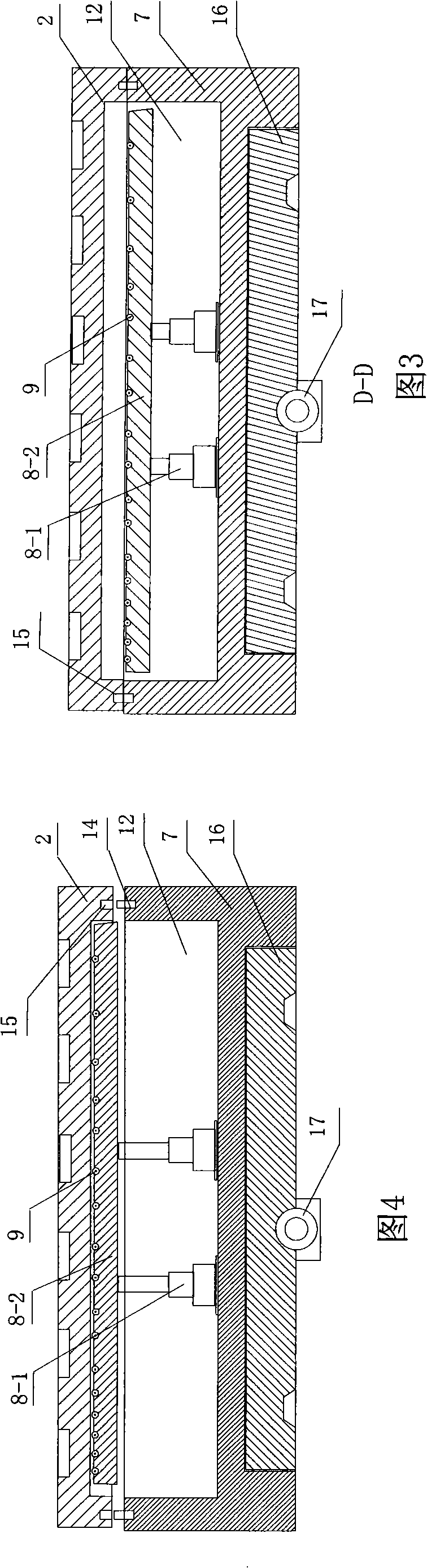

[0022] A pentahedral gantry machining center as shown in Figures 1 to 5 is divided into an exchange area A and a processing area B. The pentahedral gantry machining center has a double exchange workpiece conveying platform and has a workpiece mounting table 2 and a workpiece mounting table for fixing the workpiece 1. Supported under the workpiece mounting table 2, the workpiece 1 is pushed or pulled out of the longitudinal linear movement platform 3 of the machining center before and after the workpiece 1 is processed. A workpiece mounting platform 2 is installed in front of the longitudinal linear movement platform 3 and the workpiece 1 is pushed in and out of the longitudinal straight line The horizontal linear moving platform 4 of the moving platform 3, the longitudinal linear moving platform 3 and the horizontal linear moving platform 4 form a T-shaped structure; the horizontal moving mechanism 4 includes a transfer platform 5 and two loading and unloading arranged on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com