Involute arc spout fire-fighting extinguishing spray-head

An involute shape and involute technology, applied in the field of fire extinguishing equipment, can solve the problems of delaying fire extinguishing time, consumption of fire extinguishing agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

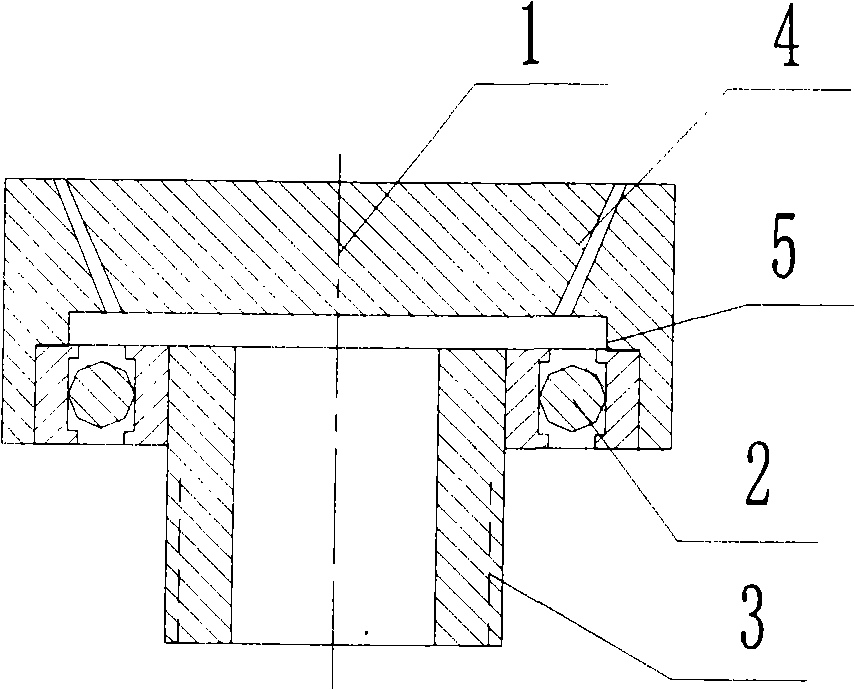

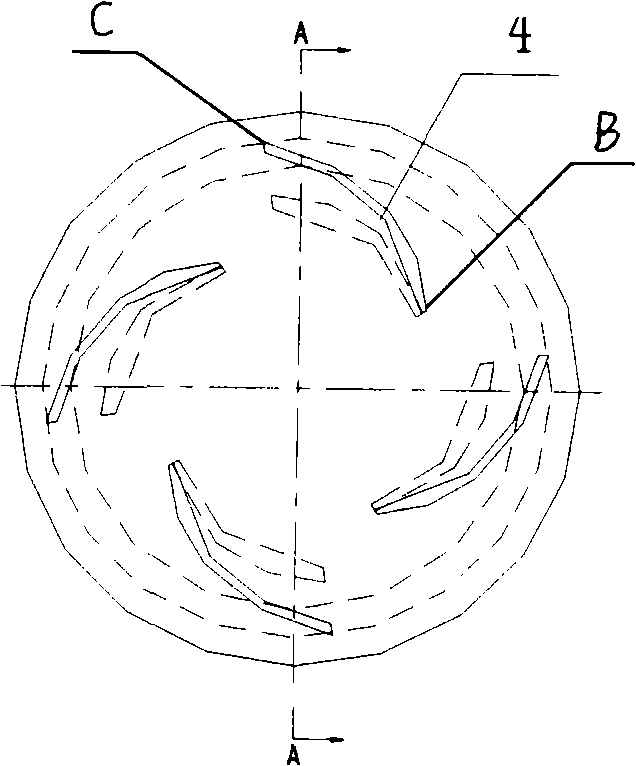

[0014] see figure 1 and figure 2 , a fire extinguishing sprinkler head with an involute arc-shaped nozzle includes a sprinkler head body 1, a bearing 2 and a connecting pipe 3. The sprinkler head body 1 is a cylinder with a diameter of 100mm and a thickness of 13mm. The cylindrical body of the concave step 5, the inner concave step end is connected to the connecting pipe 3 through the bearing 2; the other end is evenly distributed with four spout grooves, the spout grooves are involute in the radial direction, and the center of the circle is the origin of the involute; the involute The line equation is: x=r(cost+tsint), y=r(sint-tcost), where r is the radius of the base circle, with a value of 14mm, t is the spread angle, and its unit is radian, and the value of t is 90°~ 170°, 90° are the starting end B end of the involute spout groove 4, 170° are the end end C end of the involute spout groove 4, the inlet below the spout groove 4 and the outlet above form a certain spray a...

Embodiment 2

[0018] The diameter of the sprinkler head body is 90mm, and the thickness is 10mm; there are two nozzle slots evenly distributed on the sprinkler head body. The slot width is 0.5; the jet angle at the terminal end C of the involute spout slot is 40 degrees, where the slot width at the entrance of the spout slot is 0.7 mm, and the slot width at the exit is 0.6 mm; the radius r of the involute base circle is 10 mm.

[0019] Others are with embodiment 1.

Embodiment 3

[0021] The diameter of the sprinkler head body is 120mm, and the thickness is 15mm; there are three nozzle slots evenly distributed on the sprinkler head body, and the spray angle at the beginning end B of the involute nozzle slot is 80 degrees. The groove width of the involute spout groove is 2.8mm; the injection angle at the end C of the involute spout groove is 40 degrees, where the groove width of the nozzle groove inlet is 2.6mm, and the groove width of the outlet is 2.5mm; the radius r of the involute base circle is 16mm .

[0022] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com