Telescopic powder conveying pipe device

A telescopic and conveying pipe technology, which is applied in fire rescue and other directions, can solve the problems that the telescopic pipe and the carrier cannot move synchronously, the carrier (the telescopic arm cannot work normally, and the powder cannot be transported to the specified height, etc., so as to improve maintenance efficiency. The effect of shortening the fire extinguishing time and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

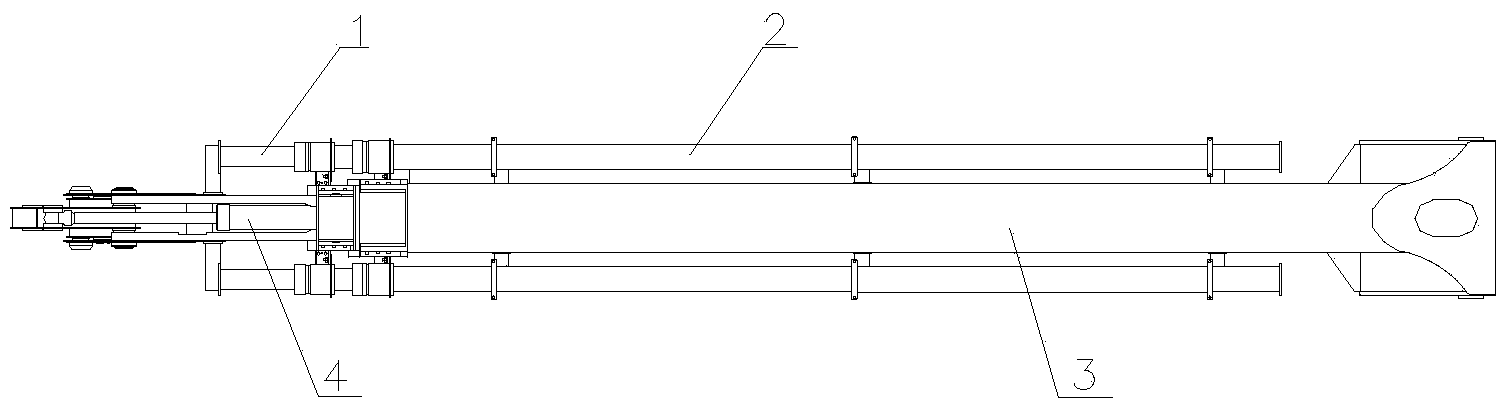

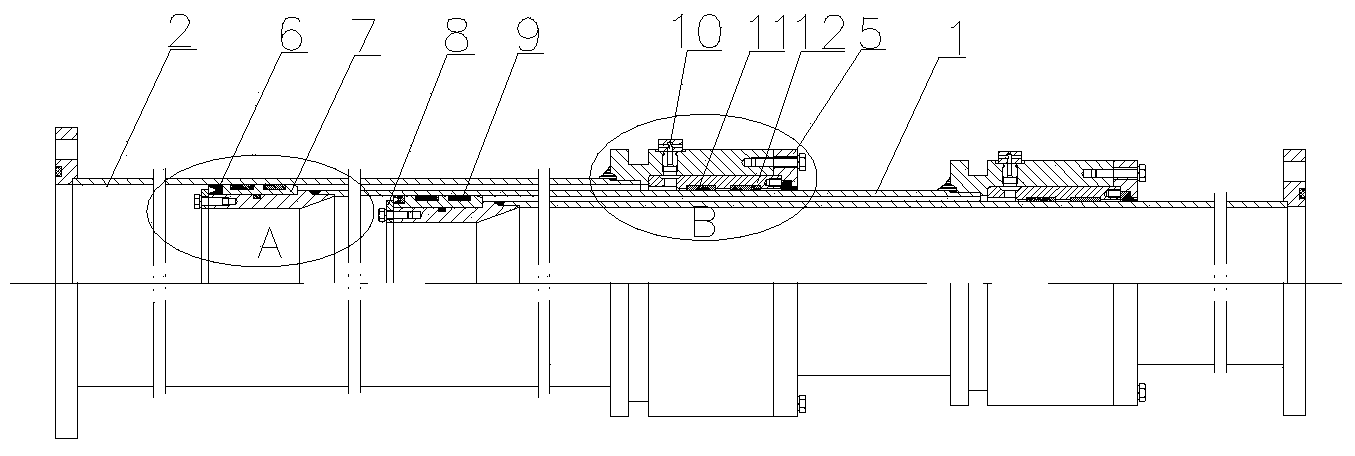

[0019] Example: Combine figure 1 , the telescopic powder conveying pipe device of the present invention is based on the telescopic boom as a carrier, and the fixed pipe 2 and the moving pipe 1 are arranged, the fixed pipe is fixedly connected with the fixed arm 3 of the telescopic boom, and the moving pipe 1 and the boom are fixed. The moving arm 4 is fixedly connected, and the moving tube 1 is coaxially inserted into the fixed tube 2 .

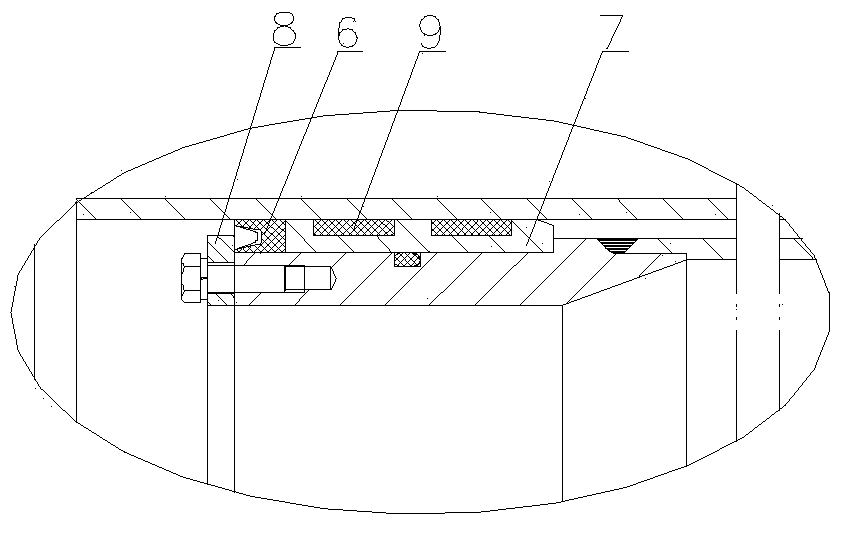

[0020] combine Figure 2-4 , the outer wall of the end of the moving tube 1 inserted into the fixed tube 2 is in the shape of a stepped shaft, that is, the outer diameter of the end of the moving tube is smaller than the outer diameter of the tube body, and a ring-shaped lower support 7 is sleeved on the part of the end of the moving tube with a small outer diameter. , the inner diameter of the lower support 7 is smaller than the outer diameter of the tube body of the motion tube, the outer diameter of the lower support is larger than the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com