Overflow-preventing energy-saving pot

An energy-saving pot and anti-overflow technology, applied in the direction of anti-overflow, etc., can solve the problems of poor environmental performance, waste of time, and single function, and achieve the effects of good heat preservation performance, fast heat absorption, and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

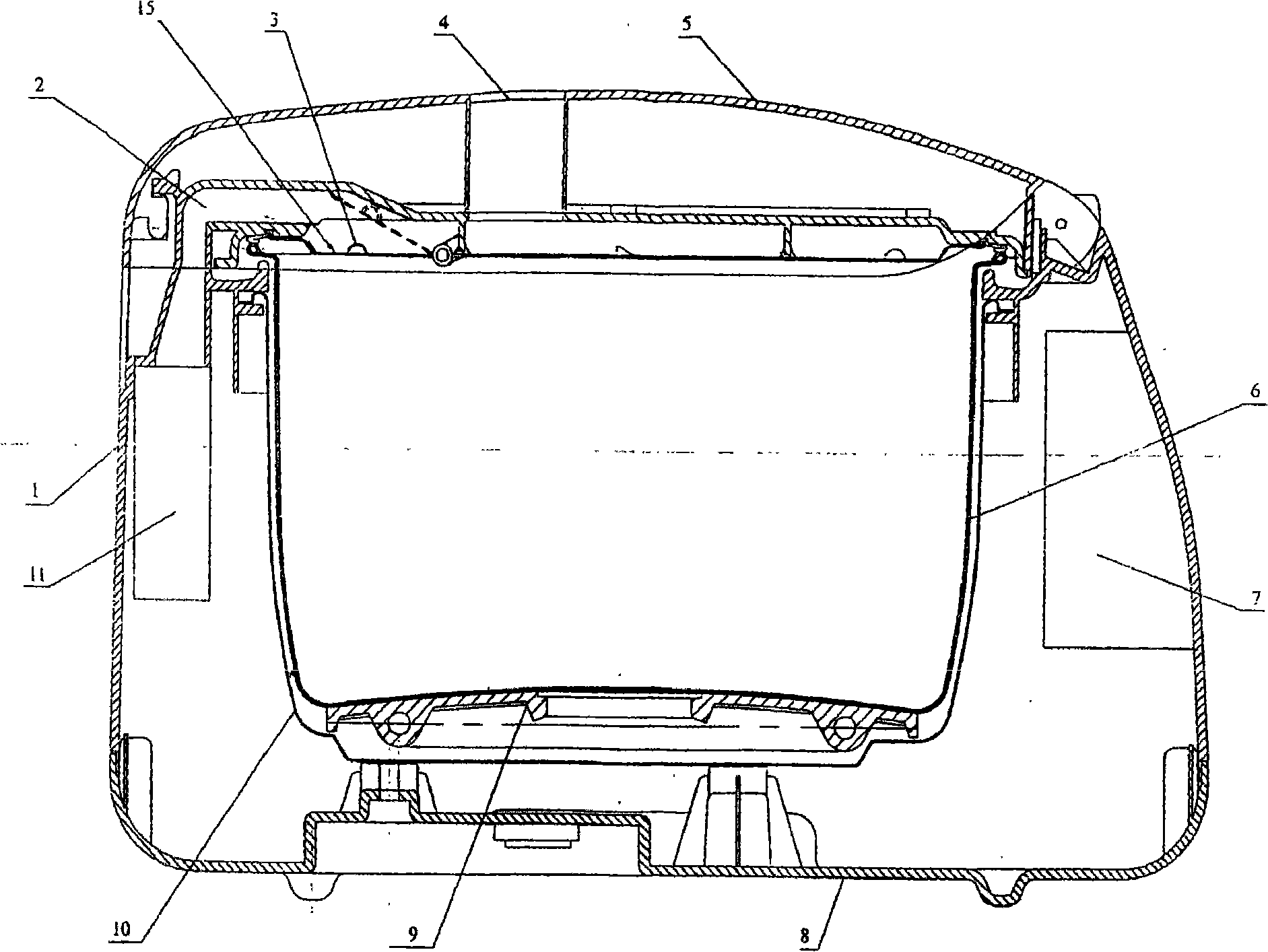

Embodiment 1

[0089] Embodiment 1: as figure 1 shown. The anti-overflow pot is composed of a pot body 1, an outer pot 10, an inner pot 6, a pot cover 5, an exhaust port 4, a heating element 9, a wire control board 7, a fan 11, an air duct 2, an air spray hole 3, a base 8, Movable wind cover 15 forms. Heating body 9 is equipped with at the bottom of outer pot 10, and wire control board 7 is equipped with at the front portion of pot body 1, and fan 11 is equipped with at the rear portion. When in use, a new generation of computer chips command several thermistors to collect temperature data of the heating element and the inside of the pot respectively, so as to realize the control of the temperature rise and fall of the heating element and the start and stop of the fan; the wind generated by the fan 11 passes through the The air duct 2 sprays into the pot from the blowing hole 3, and blows away the air bubbles generated when the liquid food is boiled, so that the boiled liquid food will not...

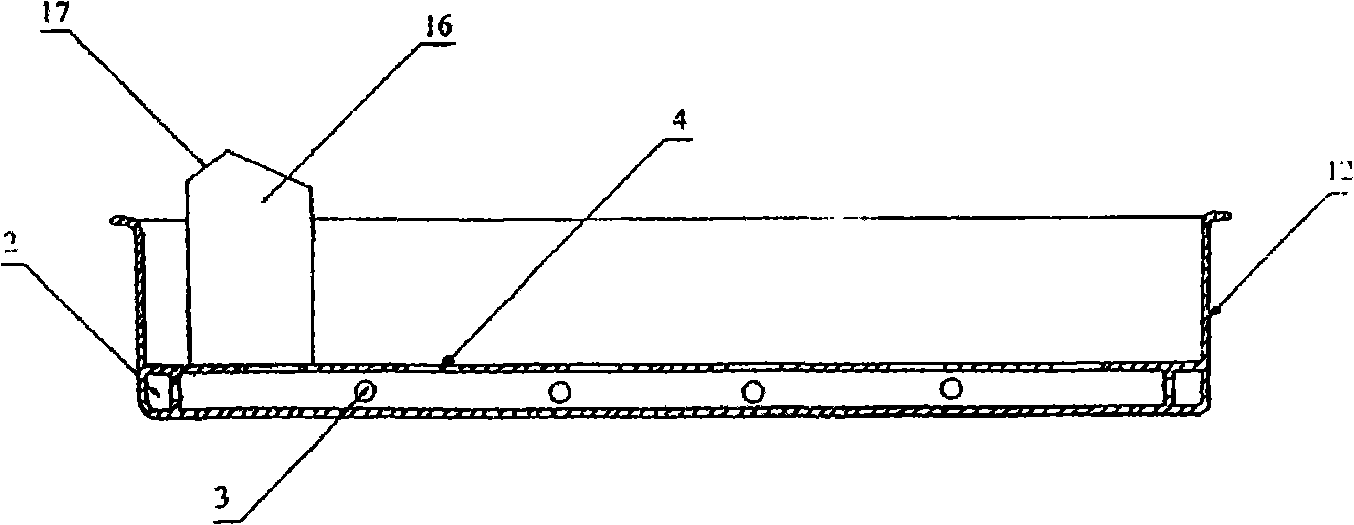

Embodiment 2

[0090] Embodiment 2: as figure 2 shown. The anti-overflow steamer is composed of a steamer 12, an air duct 16, an air inlet 17, an air duct 2, a blast hole 3, and an air outlet 4. Put the steamer 12 into the inner pot 6, the edge of the air inlet 17 can lift the movable air cover 15, so that the wind generated by the fan 11 is blown into the air inlet 17 and blows into the air duct 2 through the air pipe 16, and finally blows the air from the blowing air. The hole 3 is sprayed into the pot to blow out the bubbles generated when the liquid food is boiled, so that the boiling liquid food will not touch the bottom of the steamer. Therefore, the anti-overflow steamer can also be used to steam food while cooking liquid food, and the color, aroma, taste and shape are all good, the operation is simple, time-saving, energy-saving and hygienic.

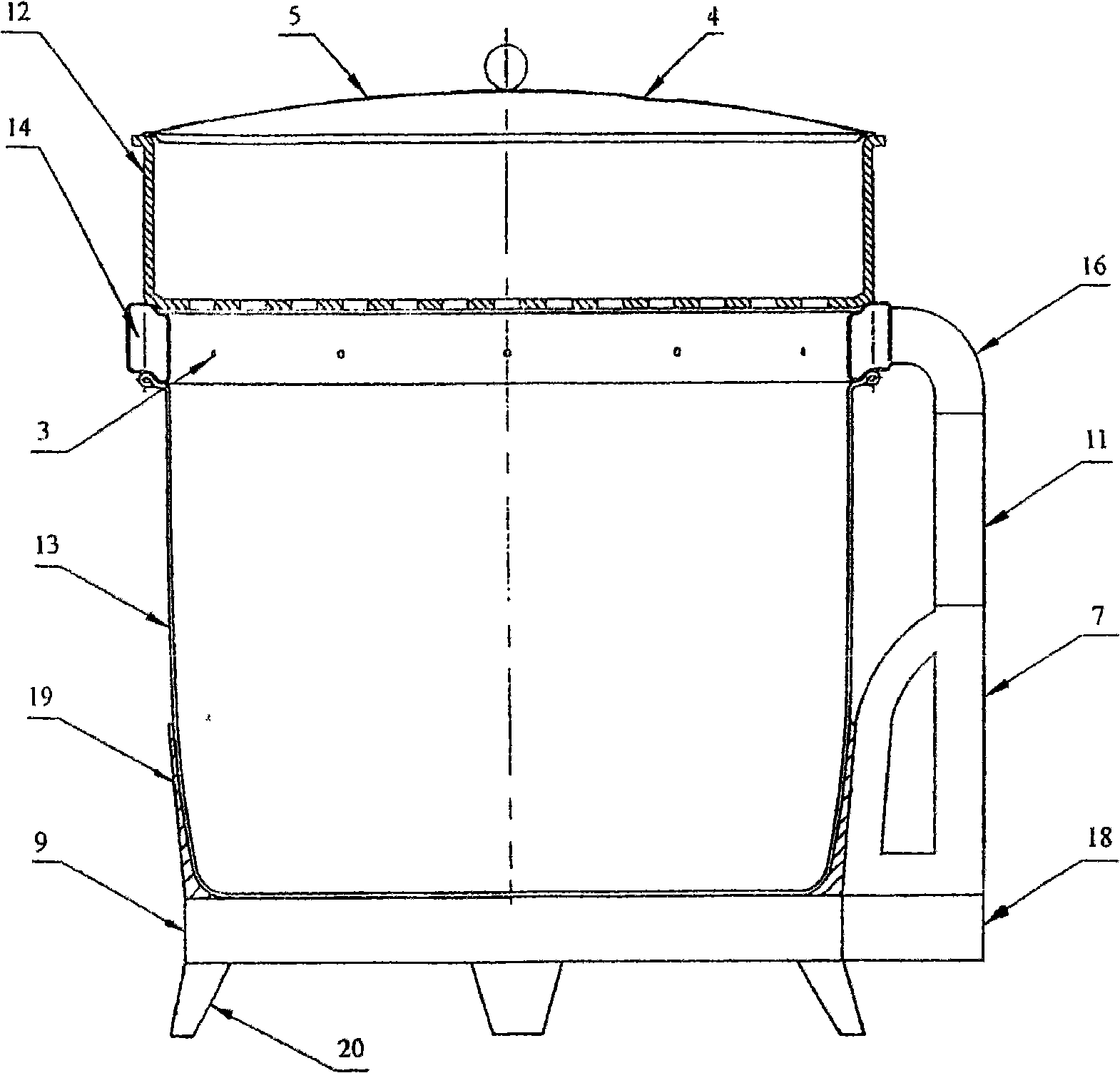

Embodiment 3

[0091] Embodiment 3: as image 3 shown. The simple anti-overflow pot is composed of a pot body 13, a pot base 19, a heating element 9, a tripod 20, a pot cover 5, an exhaust port 4, a support plate 18, a wire control board 7, a fan 11, an air duct 16, a movable Air duct 14, blast hole 3, steamer 12 are formed. An active air duct 14 is installed on the edge of the upper mouth of the pot body 13, and a support plate 18 is installed on the outside of the heating element 9. On the support plate 18, a wire control board 7 and a blower fan 11 are installed successively, and are welded on the active air duct. The lower end of the air duct 16 on the outside of 14 is connected to the air outlet of the blower fan 11 . Steamer 12 is placed on movable air channel 14. A new generation of computer chips command several thermistors to collect the temperature data of the heating element (chassis) and the pot respectively, so as to realize the control of the temperature rise and fall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com