Clamping plate type corrosion resistant abrasion-proof slurry pump

A wear-resistant sand and splint-type technology, applied in non-variable-capacity pumps, non-displacement pumps, pumps, etc., can solve the problems of leakage at the root of the impeller, affecting the service life of the mortar pump, leakage, etc., so as to prolong the service life and improve the Effect of anti-leakage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

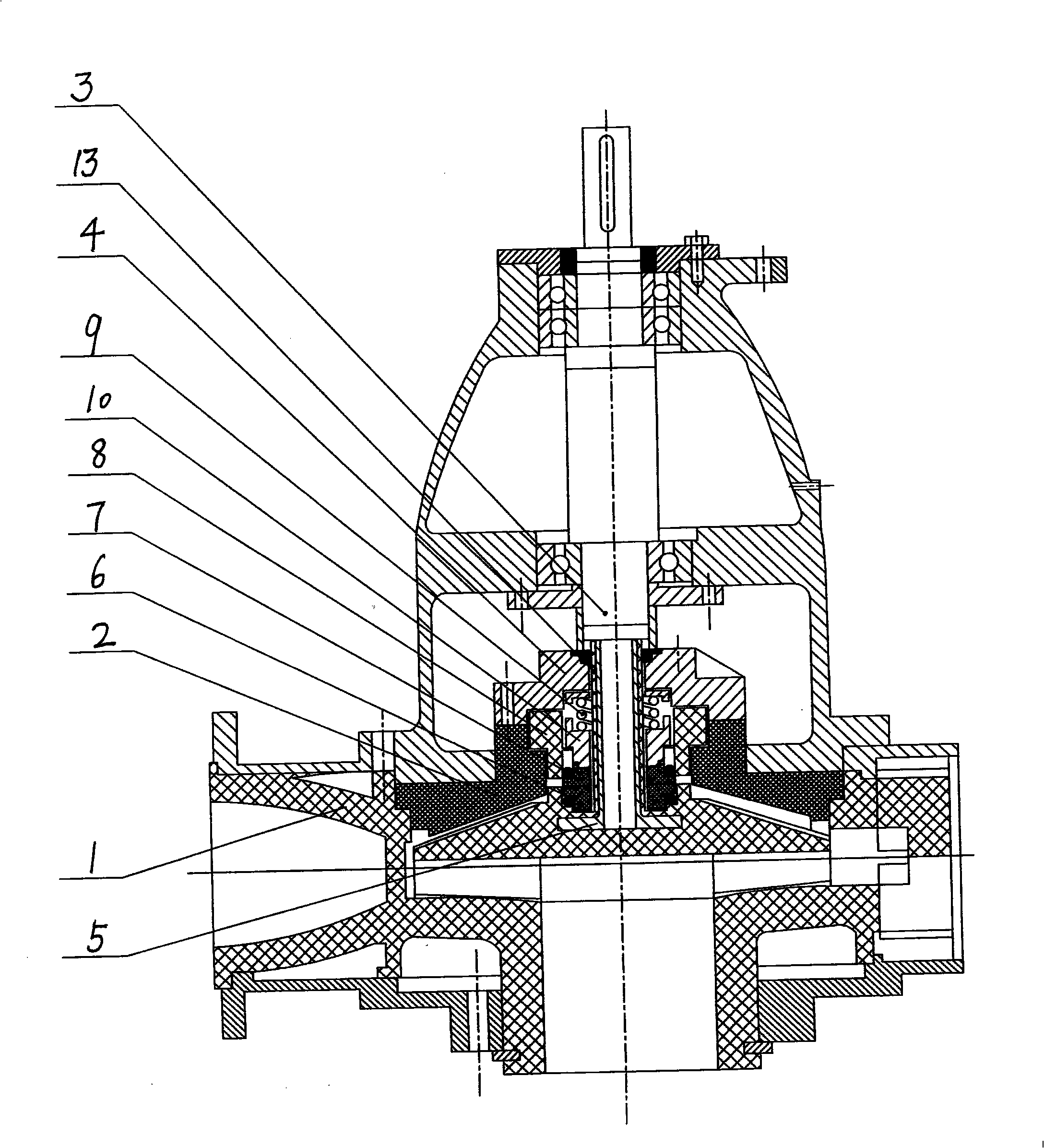

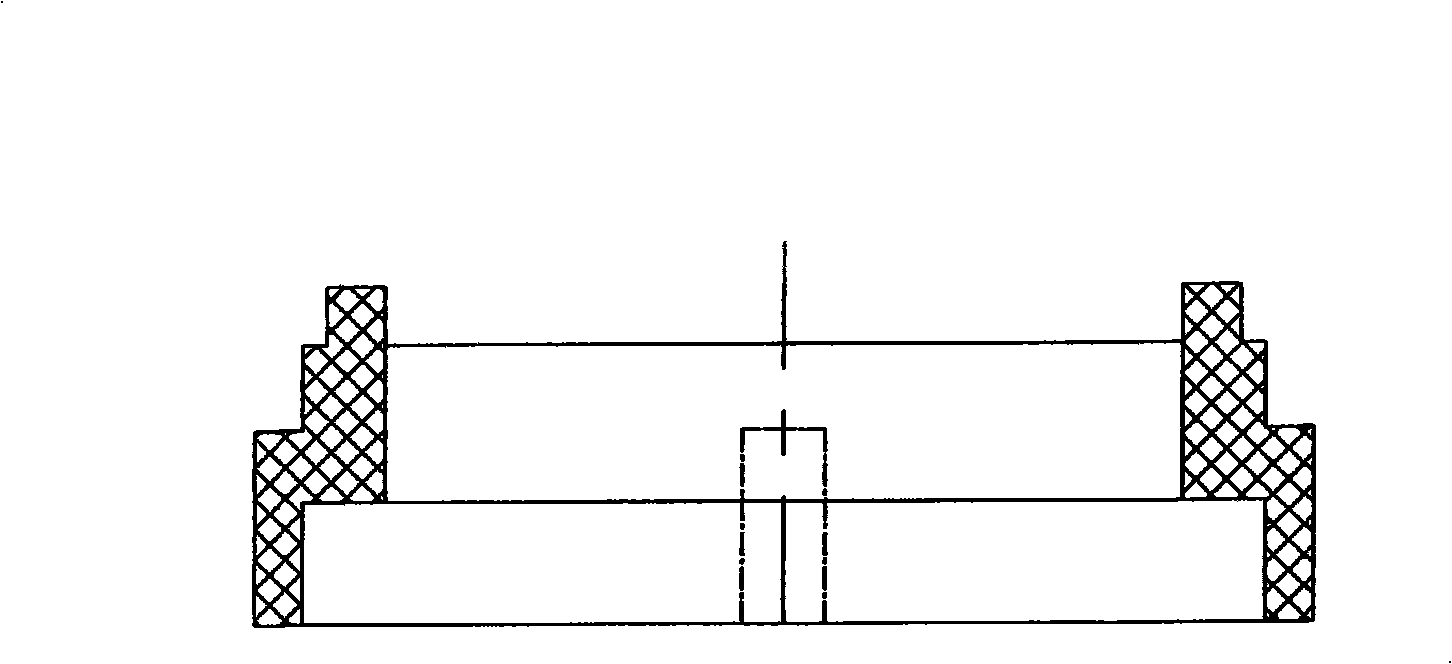

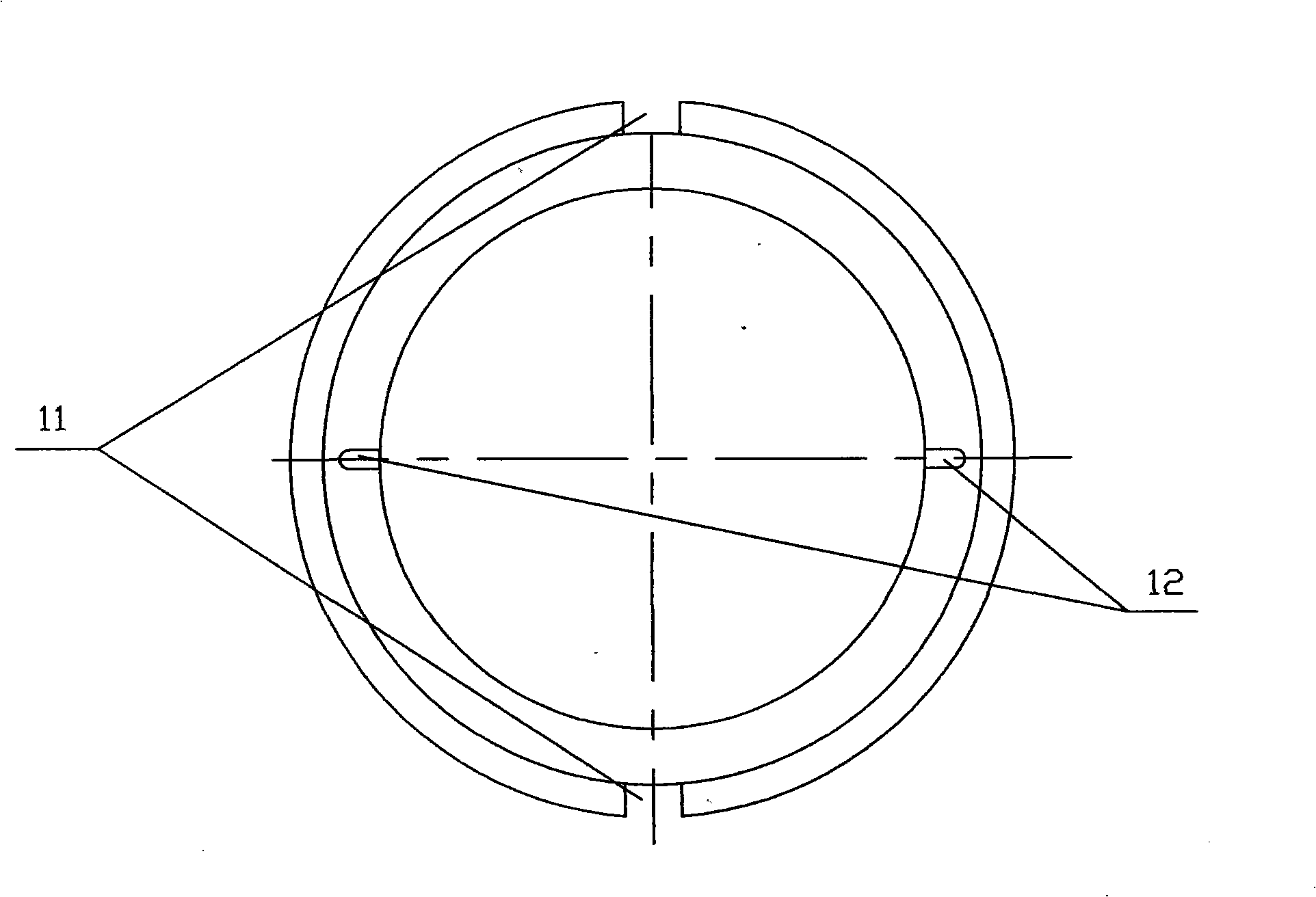

[0012] As can be seen from the accompanying drawings, the present invention includes a pump body 1, a pump cover 2, a shaft 3, a sealing box 4, an impeller 5 and a mechanical sealing device, and the mechanical sealing device is arranged in the sealing cavity formed by the pump cover 2, the impeller 5 and the sealing box 4 , the mechanical seal device is composed of a moving ring 6, a static ring 7, a static ring seat 8, a spring 9 and a spring seat 10, the spring seat 10 is set in the static ring seat 8, and one end is provided with two seams 11, and the other end is provided with There are two bosses 12, the spring seat 10 is positioned through two seams 11 at one end and the two bosses of the static ring seat 8, the static ring 7 is set in the static ring seat 8, and passes through the two seams on it It is positioned with two bosses 12 at the other end of the spring seat 10, the moving ring 6 is positioned with the impeller 5 through the seam thereon, and the friction surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com