Paper surface electrostatic painting process and special high pressure electrostatic painting system therefor

An electrostatic spraying and high-voltage electrostatic technology, applied to paper and other directions, can solve the problems of unsatisfactory flickering effect of pearl paper, the inability of the coating surface to be uniform and uniform, and the low utilization rate of coatings, so as to achieve strong flickering effect and uniform coating surface. Smooth and consistent, high paint utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

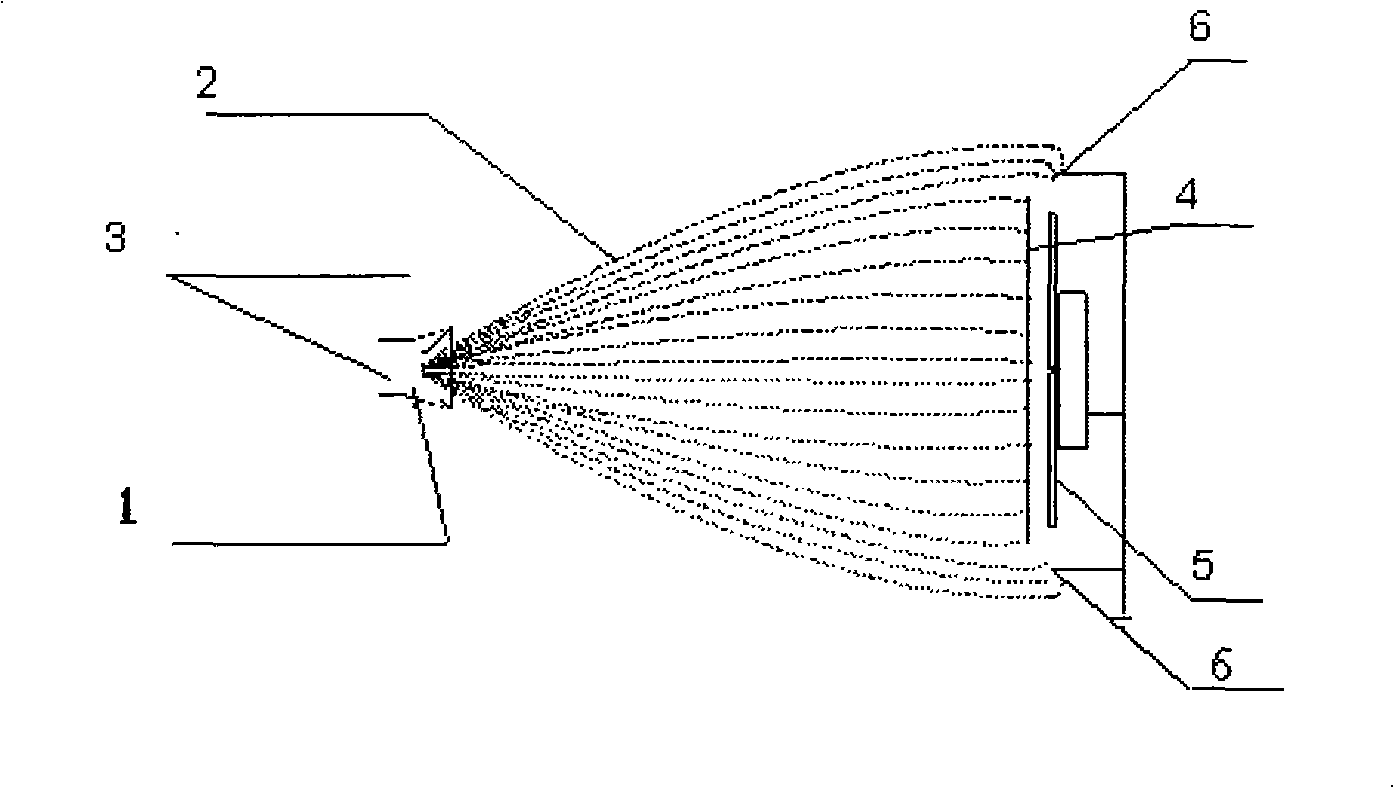

Embodiment 1

[0061] Preparation of spray paint: 100 grams of resin vinyl acetate, 60 grams of solvent butyl acetate and ethyl acetate and 16 grams of pearl powder are mixed to prepare spray paint. The above-mentioned high-voltage electrostatic spraying system is used to make the paper move close to the positive metal plate in the working electric field formed by the spray gun and the metal plate. The working voltage of the working electric field is 90KV, and the distance between the spray gun and the metal plate is 200mm. The caliber is 60mm, and the rotating cup speed is 3000 rpm. The spray paint prepared above is input into the spray gun, and the charged paint particles ejected from the spray gun move to the positive metal plate under the action of high-voltage electric field, and are accepted and deposited on the surface of the paper by the paper to form a coating layer.

Embodiment 2

[0063] Preparation of spray paint: 200 grams of resin vinyl acetate, 120 grams of solvent butyl acetate and ethyl acetate and 80 grams of pearl powder are mixed to prepare spray paint. The above-mentioned high-voltage electrostatic spraying system is used to make the paper move close to the positive metal plate in the working electric field formed by the spray gun and the metal plate. The working voltage of the working electric field is 60KV, and the distance between the spray gun and the metal plate is 250mm. The caliber is 60mm, and the rotating cup speed is 10000 rpm. The spray paint prepared above is input into the spray gun, and the charged paint particles ejected from the spray gun move to the positive metal plate under the action of high-voltage electric field, and are accepted and deposited on the surface of the paper by the paper to form a coating layer.

Embodiment 3

[0065] Preparation of spray paint: 300 grams of resin vinyl acetate, 180 grams of solvent butyl acetate and ethyl acetate and 96 grams of pearl powder are mixed to prepare spray paint. The above-mentioned high-voltage electrostatic spraying system is used to make the paper move close to the positive metal plate in the working electric field formed by the spray gun and the metal plate. The working voltage of the working electric field is 80KV, and the distance between the spray gun and the metal plate is 220mm. The caliber is 60mm, and the rotating cup speed is 5000 rpm. The spray paint prepared above is input into the spray gun, and the charged paint particles ejected from the spray gun move to the positive metal plate under the action of high-voltage electric field, and are accepted and deposited on the surface of the paper by the paper to form a coating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com