Large area anti-reflection conductive film continuous magnetron sputtering film coating production line

A magnetron sputtering coating, conductive film technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the complex process, can not complete the preparation of anti-reflection film and coating transparent conductive film at one time, Coating materials are limited and other problems, to achieve the effect of convenient process debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

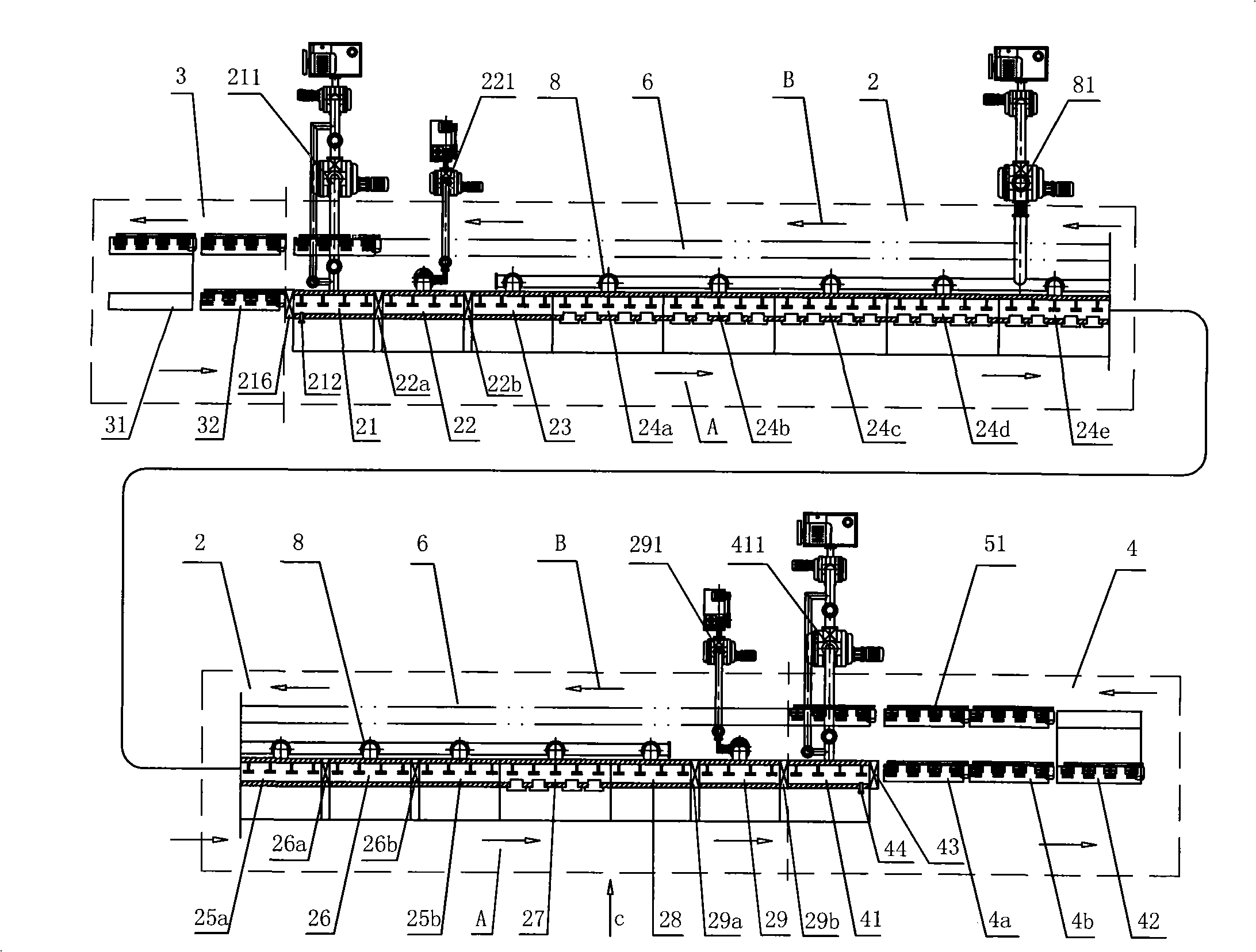

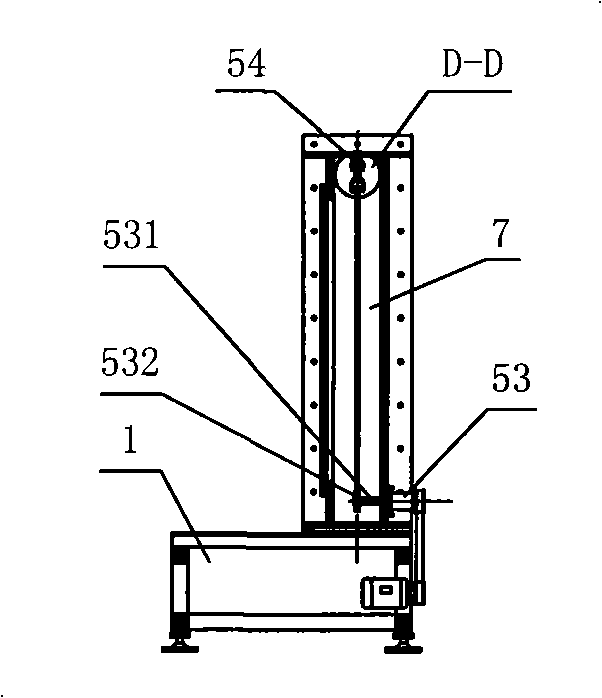

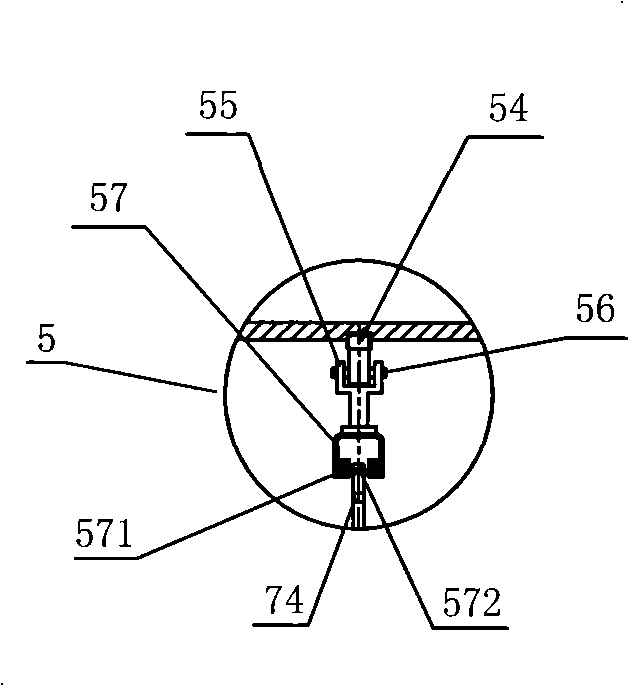

[0037] As shown in the accompanying drawings, a large-area anti-reflective conductive film continuous magnetron sputtering coating production line, which includes several pre-pumping chambers 21 that are successively adjacent to each other in the transverse direction of the machine base 1 and communicate with the pumping system. , the front transition chamber 22, the front transfer chamber 23, the dielectric film coating chamber I24a, the dielectric film coating chamber II24b, the dielectric film coating chamber III24c, the dielectric film coating chamber IV24d, the dielectric film coating chamber V24e, the isolation transfer chamber I25a, the isolation chamber 26, Isolate the vacuum chamber group area 2 formed by the transfer chamber II25b, the conductive film coating chamber 27, the rear transfer chamber 28 and the rear transition chamber 29, and the adjacent film-in area 3 and the film-out area 4. The film-in area 3 is composed of a film-in translation frame 31, a frame 32, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com