Combined bell glass washer and operation method thereof

A cleaning machine and combined technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of poor sealing performance, increase production costs, and high costs, and reduce equipment failure rates. The effect of extended service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

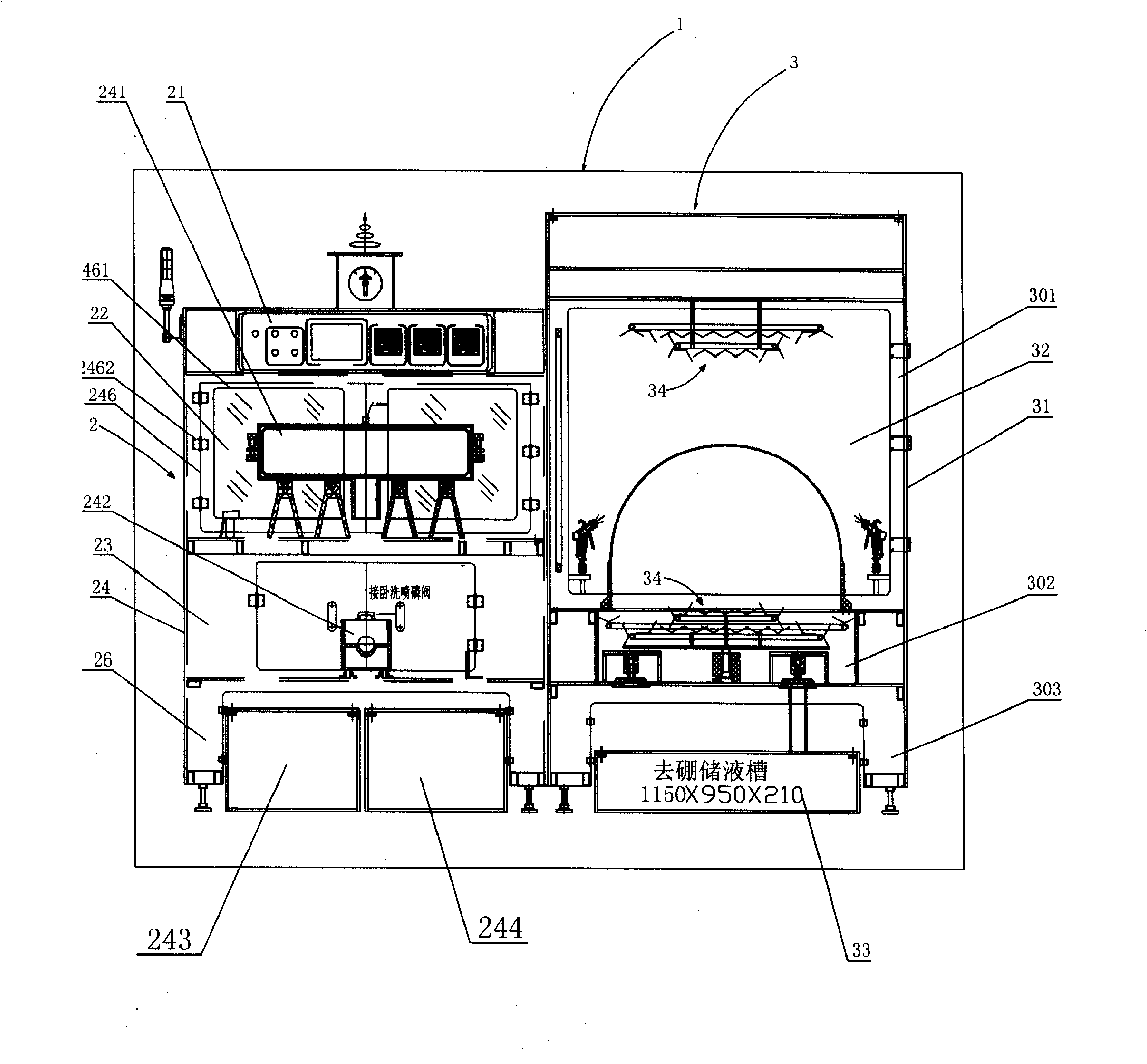

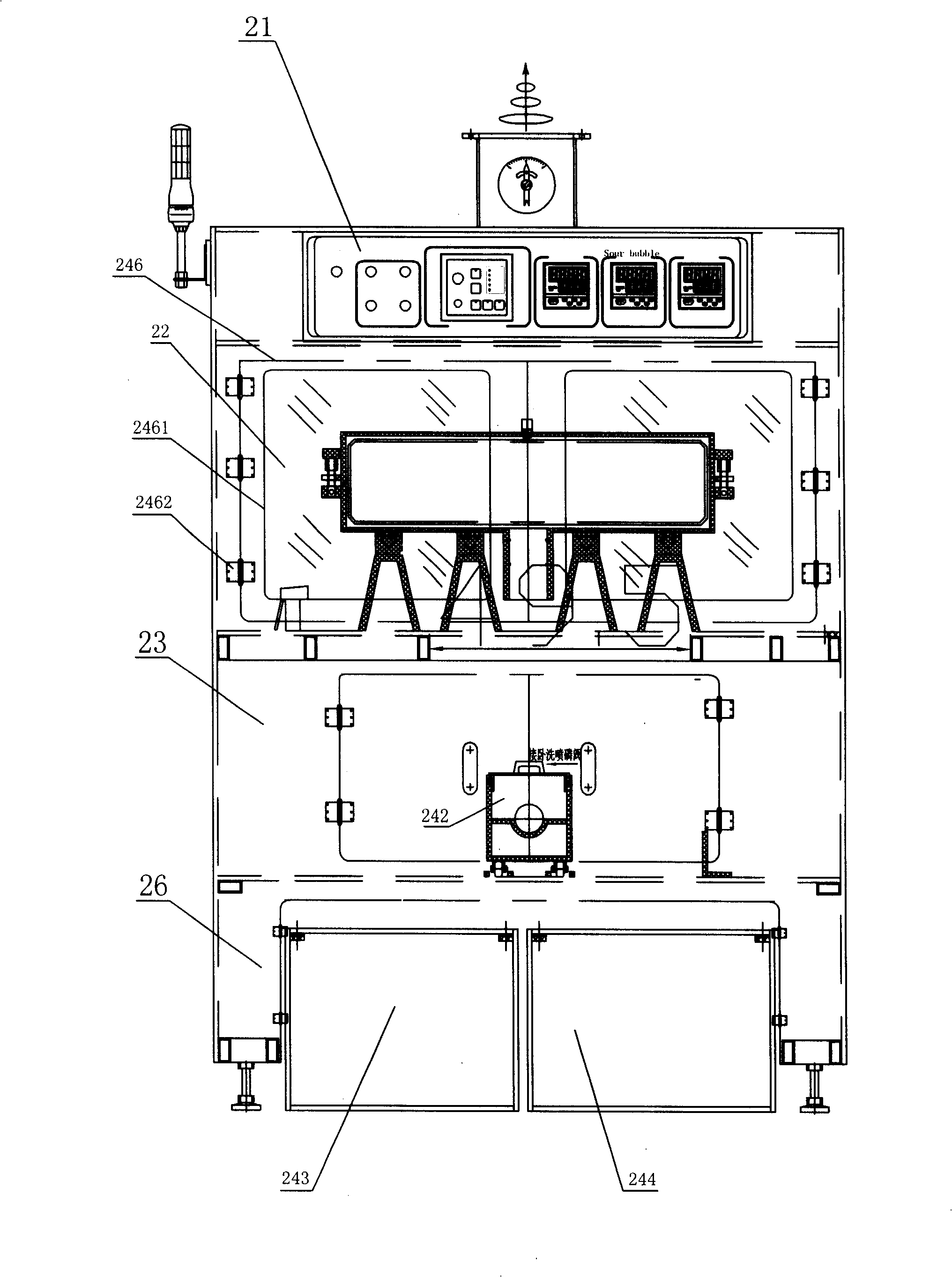

[0045] see figure 1 Shown in -7, a kind of combined bell jar washing machine of the present invention, it comprises casing 1, horizontal quartz bell jar washing machine 2 and vertical quartz bell jar washing machine 3; Described horizontal quartz bell jar washing machine 2 is arranged on box On the left side of the body 1, the vertical quartz bell jar cleaning machine 3 is arranged on the right side of the box body 1;

[0046] The horizontal quartz bell jar cleaning machine 2 is divided into an electrical appliance shelving area 21, a horizontal bell jar cleaning area 22, a supporting parts cleaning area 23 and a liquid storage tank placement area 26 from top to bottom;

[0047] The vertical quartz bell jar cleaning machine 3 is divided into a bell jar cleaning area 301 , a two-fluid spray pipeline and liquid recovery area 302 and a liquid storage tank placement area 303 from top to bottom.

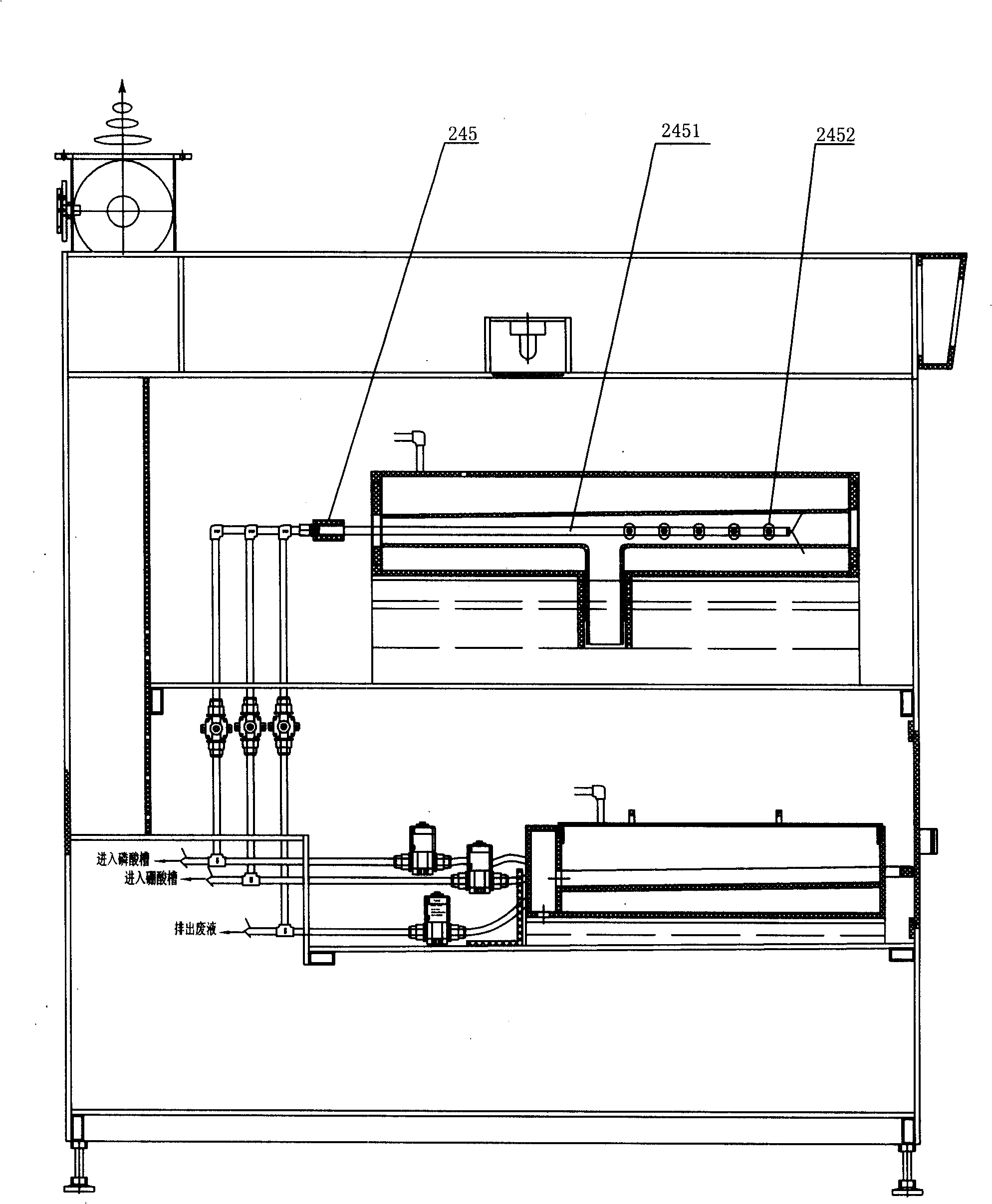

[0048] For further improved embodiments, see figure 1 , 2 , 3, 4, and 7, the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com