Method and device for processing explosion exhaust air

A treatment method and exhaust gas technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of huge equipment, unstable salt products, transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

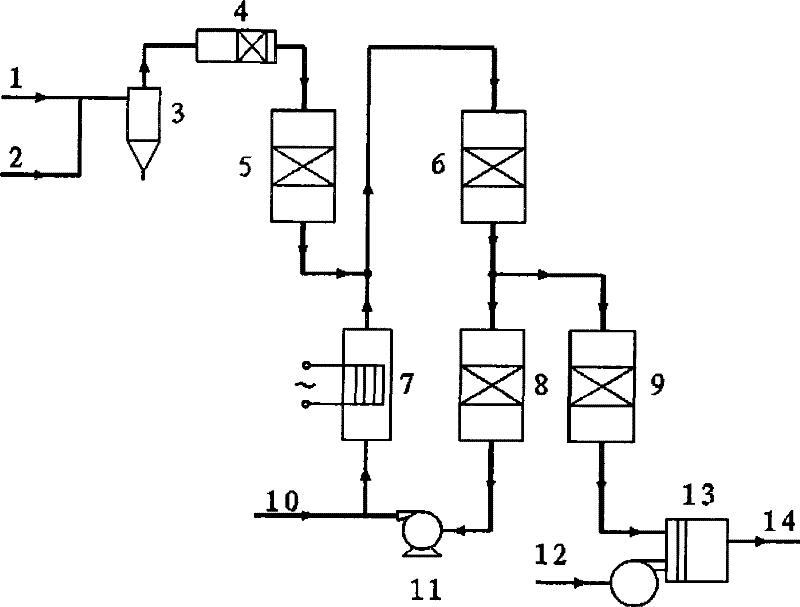

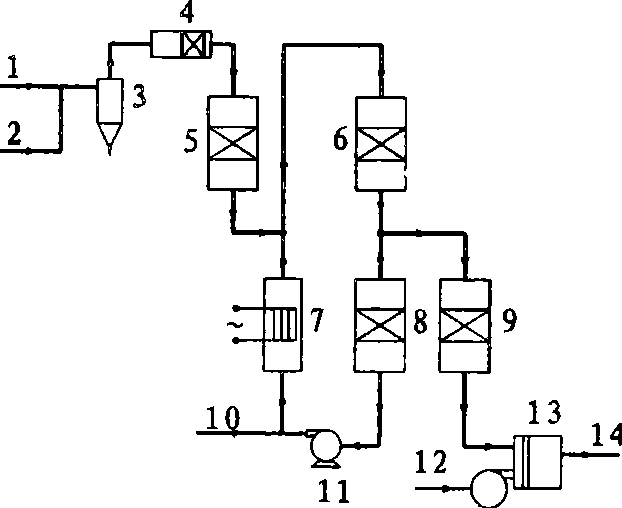

[0024] The present invention will be further described below in conjunction with accompanying drawing.

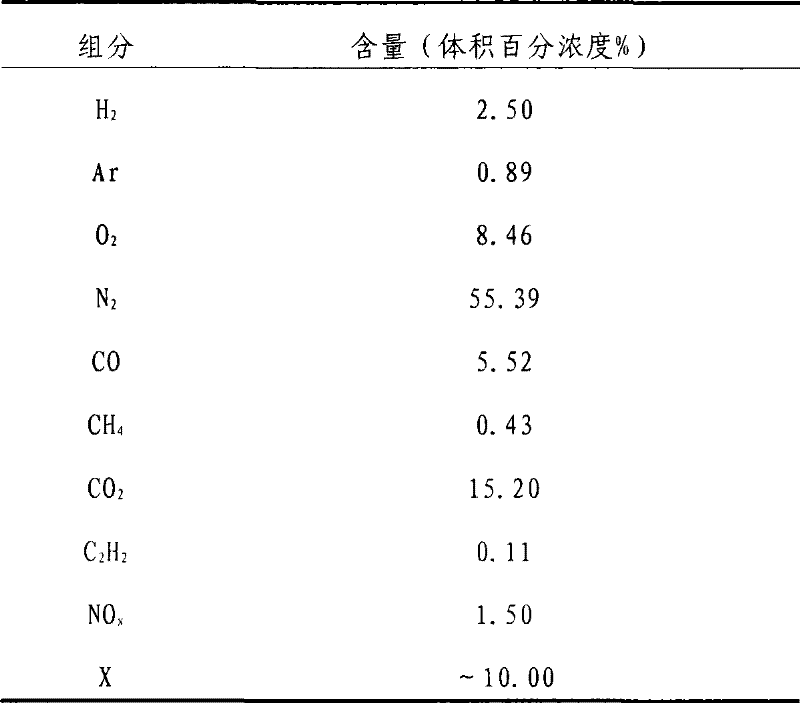

[0025] The example of the present invention takes the exhaust gas treatment of a certain explosion experimental device as an example. After the explosion experiment of the explosion experiment device, the product contains a small amount of heavy metal particles and NO, NO 2 Mixed gases of harmful substances such as Table 1 shows the gas composition in the explosive device after the explosion experiment.

[0026] Firstly, the exhaust gas treatment process is carried out:

[0027] Explosion waste gas 1 enters cyclone filter 3 to remove large granular objects such as sawdust and paper scraps produced after the explosion; then enters high-efficiency filter 4 to remove heavy metal ions in the explosion product aerosol; then enters molecular sieve dehydrator 5 for dehydration Then enter NOx adsorber 6 to absorb NOx; After adsorption, gas enters deodorizer deodorization 9; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com