Connecting system for conduits, fittings or assemblies

A connection system and assembly technology, applied in the direction of stuffing seal connection, sleeve/socket connection, pipe/pipe joint/fitting, etc. with fluid pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

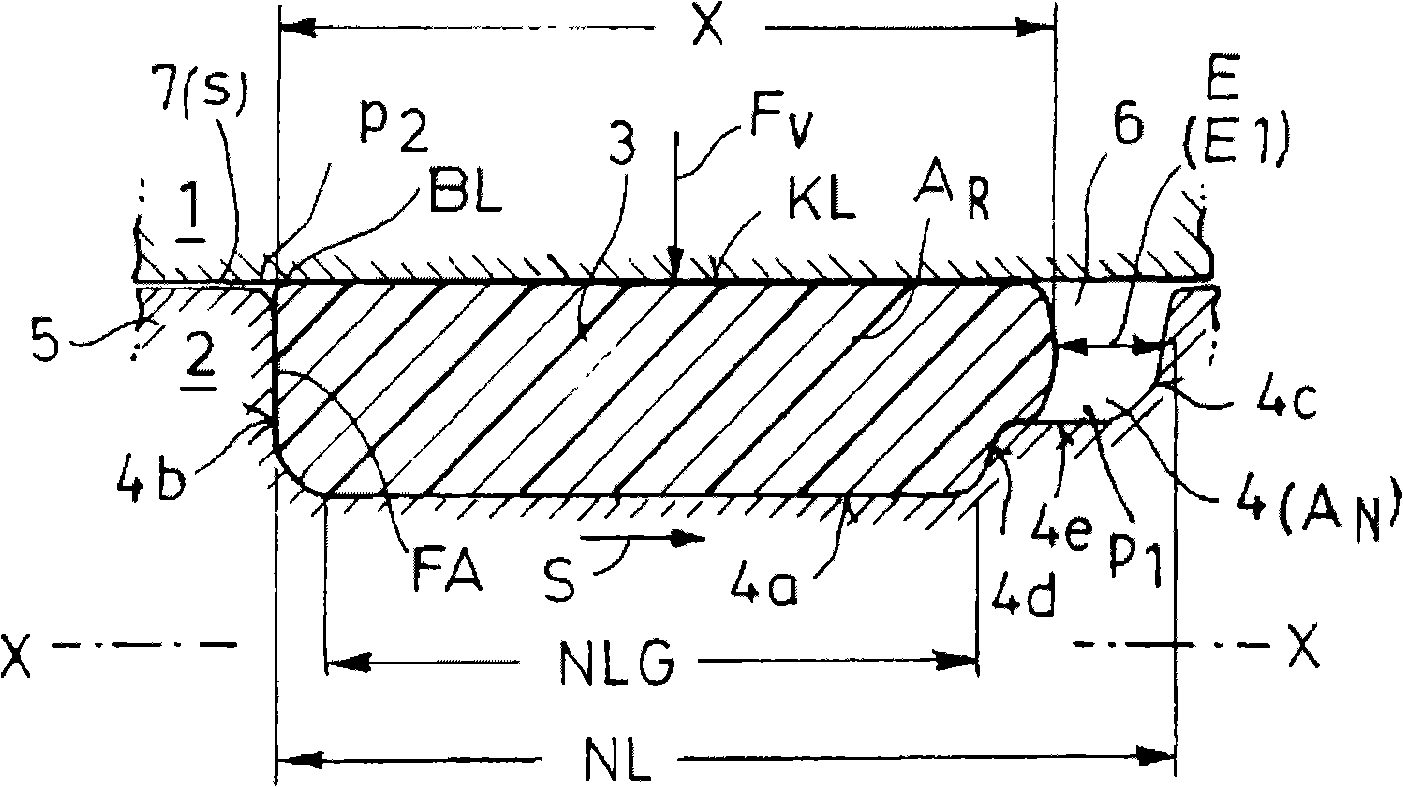

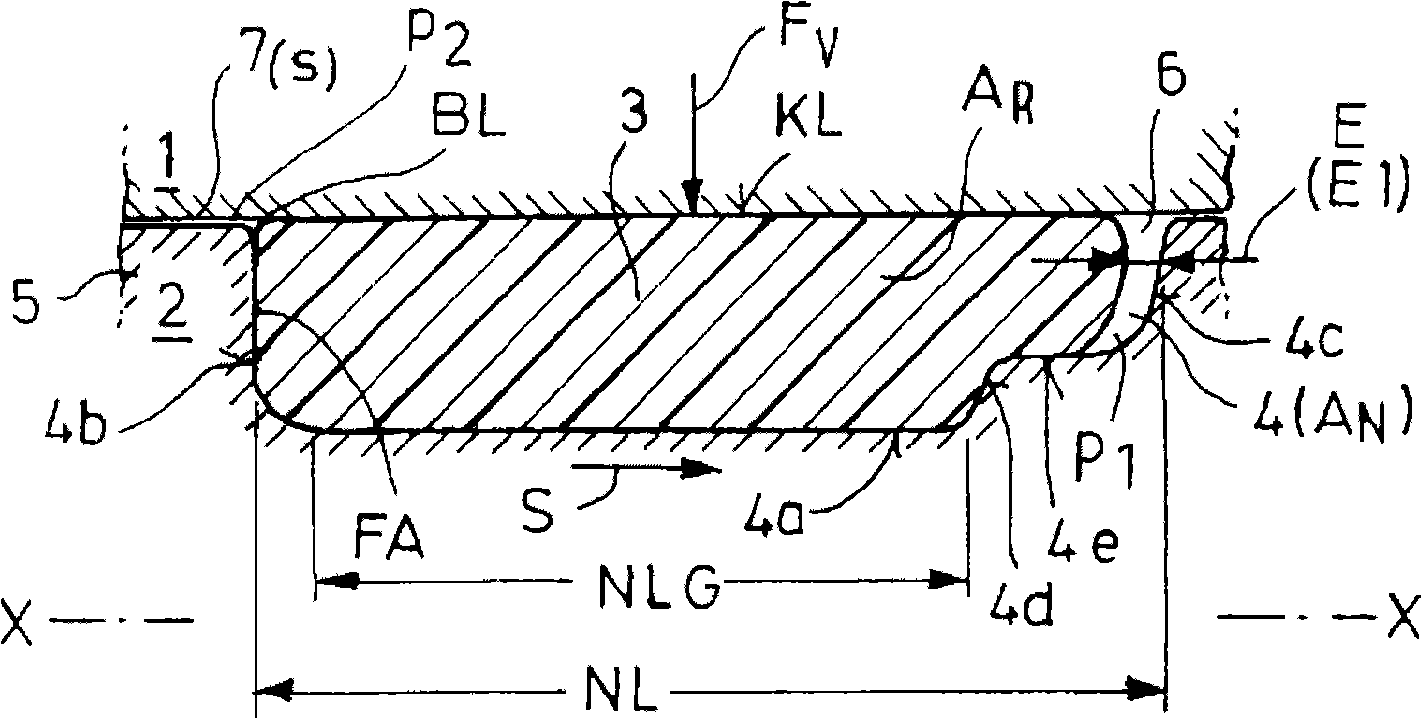

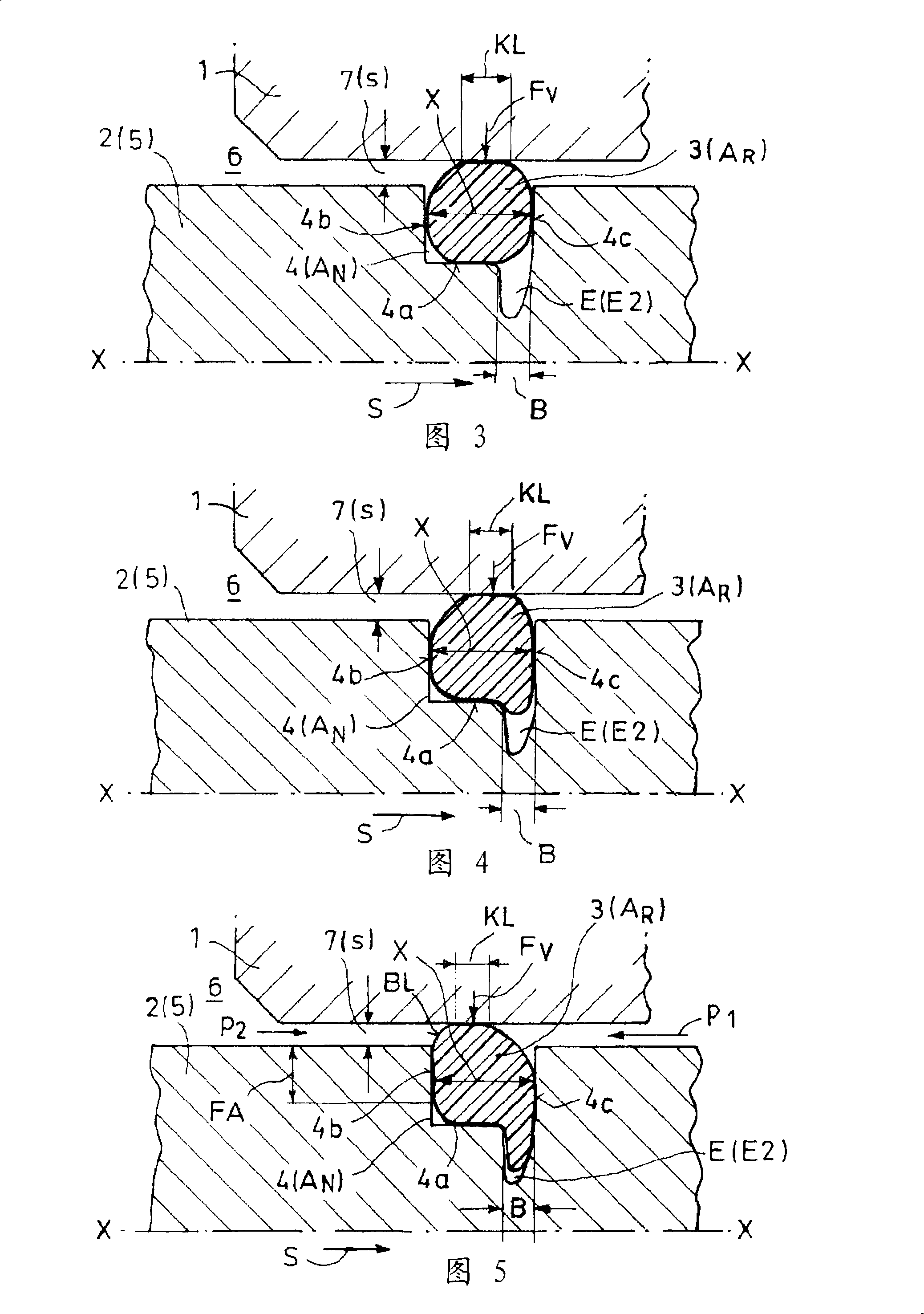

[0035] In the above-mentioned views of the drawings, identical parts are always assigned the same reference numerals and are therefore generally described each only once below.

[0036] first as figure 1 and 2 It can be seen that, according to the invention, a connection system for pipes, fittings or assemblies intended for use at pressures above the comparative pressure p 2 pressure p 1 To conduct a fluid down, the system comprises a first connection part 1 (for example a housing part), a second connection part 2 (for example a plug part), which can be connected to the first connection part 1, and by At least one peripheral seal 3 constituted by an elastomer and arranged in a groove 4 .

[0037] The first connecting part 1 and / or the second connecting part 2 can consist of plastic or preferably of a metallic material.

[0038] The peripheral seal 3 may preferably be made of polymeric fluorocarbon or synthetic rubber (such as silicone rubber, nitrile rubber (NBR) or H-NBR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com