High temperature resistant self-lubricating deep groove ball bearing

A deep groove ball bearing and self-lubricating technology, applied in the direction of ball bearings, bearing components, shafts and bearings, can solve problems such as economic losses, production delays, and inability to use life, so as to prevent offset jamming and improve flexibility The effect of resistance and load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and example content of the present invention will be further described:

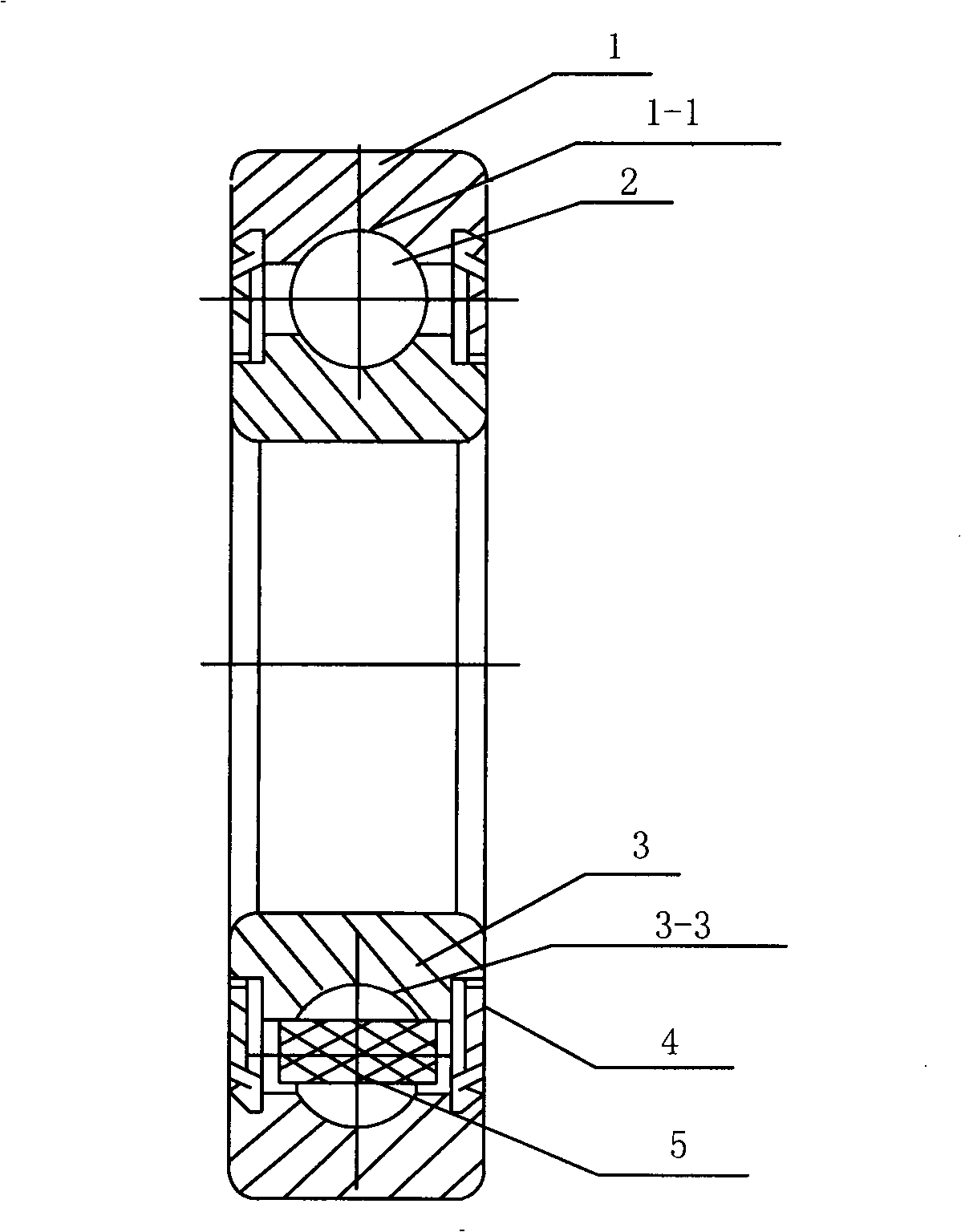

[0015] refer to figure 1 , the bearing of the present invention is composed of bearing outer ring 1, inner ring 3, steel ball 2 fitted between outer ring 1 and inner ring 3, graphite block 5 sandwiched between steel balls 2, two inner circular wall surfaces embedded in outer ring 1 Side dust cover 4 composition. The steel ball 2 is a sphere, the graphite block 5 is a cube, and a rolling groove 1-1 is arranged on the middle part of the inner circular wall surface of the outer ring 1 to accommodate the steel ball 2, and the depth of the groove 1-1 is the diameter of the steel ball 2. 1 / 8 to 1 / 2, the middle part of the outer circular wall of the inner ring 3 is also provided with a rolling groove 3-3 for holding the steel ball 2, and the depth of the groove 3-3 is also 1 / 2 of the diameter of the steel ball As the standard, the graphite block 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com