Zinc based titanium alloy coating process for mechanical plating

A mechanical galvanizing and titanium alloy technology, applied in the direction of pressure inorganic powder coating, etc., to achieve the effect of good overall performance of the coating, low energy consumption, and less process pollution

Inactive Publication Date: 2010-11-10

KUNMING UNIV OF SCI & TECH

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The mechanical plating process of a single metal, such as mechanical Zn plating, has been successfully applied to industrial production; the research and small-batch application of zinc-based aluminum, copper, tin, and rare earth alloy coatings obtained by mechanical plating are developing rapidly, while the mechanical plating method Obtain zinc-based titanium alloy coating, there is no report on research and industrial application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

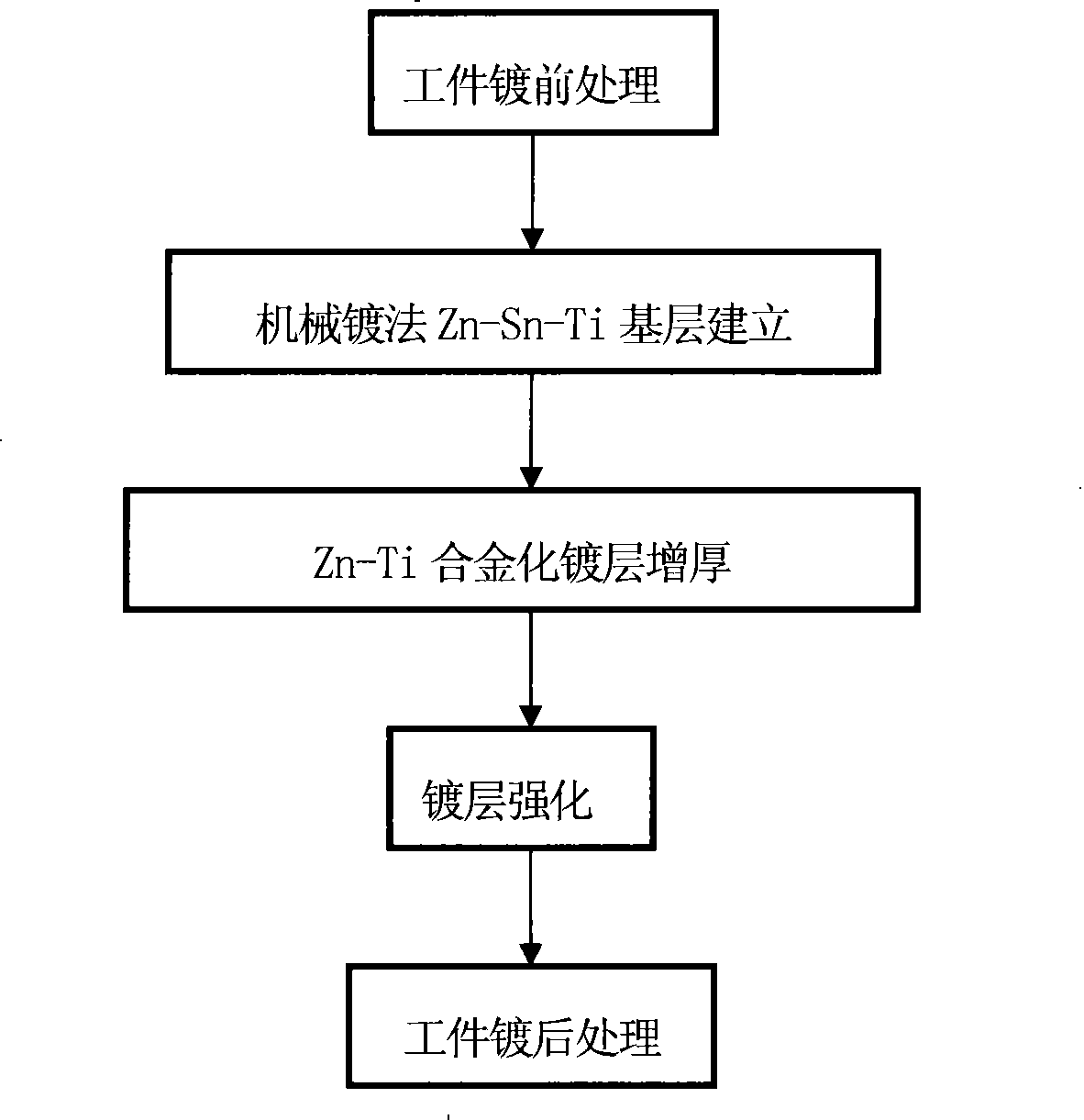

The invention puts forward a method for forming Zn-Ti alloy plating on the surface of a steel part by adding titanium salts in a mechanical plating process, belonging to the technical field of a surface plating process. The method comprises the following processes of treating a workpiece before plating, building a base layer, thickening alloyed plating, strengthening the plating, etc. After the workpiece is treated before plating at a normal temperature and pressure by use of a mechanical plating method, the workpiece is put into a plating cylinder having impact media and water; then zinc powder, stannous and inorganic titanium salt solution are added in, and the plating cylinder is rotated so as to form an alloy base layer on the surface of a steel matrix; surfactant, sedimentary activator, inorganic titanium salt water-soluble additive and zinc powder are added in for thickening the alloyed plating; and finally, water is added in and the plating cylinder is rotated, so as to strengthen the organization structure of the plating. As inorganic titanium salts are added in the mechanical plating process, under the action of plating solution and an impacting fluid state environment inthe plating cylinder, the titanium salts can improve the deposition characteristics of the metallic zinc powder and are partially reduced and precipitated, so as to increase the strength, hardness and corrosion resistance of the plating.

Description

Coating process of mechanical galvanized titanium alloy Technical field: The invention relates to a process for obtaining a zinc-based titanium alloy coating on the surface of iron and steel parts by means of mechanical plating. In particular, the method of mechanical plating uses inorganic titanium salt additives to form mechanical zinc-based titanium on the surface of iron and steel parts. Alloy coating (Zn-Ti) method. The invention belongs to the technical field of surface coating technology of iron and steel materials. technical background: The most widely used metal material in industrial and agricultural production is steel. The corrosion resistance of steel materials is poor, and the surface is very easy to oxidize pig iron, so it needs to be protected before use. At present, the main technologies for steel surface anticorrosion are hot-dip plating and electroplating. Since the thinner electroplating coating is not suitable for the surface protection of steel pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C24/04

Inventor 赵晓军王胜民何明奕钟福平刘丽谭蓉彭增华

Owner KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com