White polyester film

A polyester film, white technology, used in layered products, transportation and packaging, synthetic resin layered products, etc., can solve problems such as high brightness and high concealment that are difficult to deal with, and achieve both productivity and performance, low cost. , high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

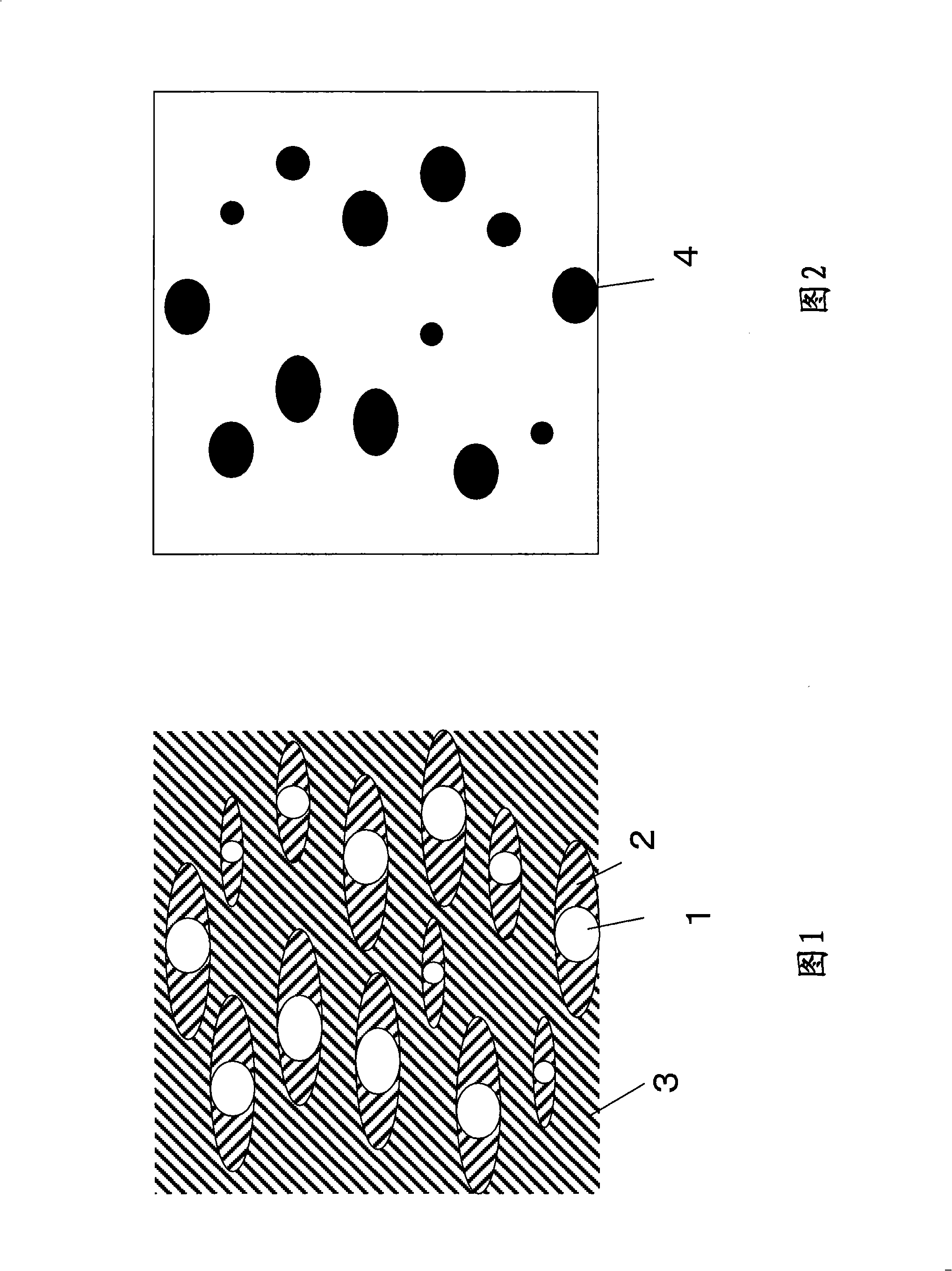

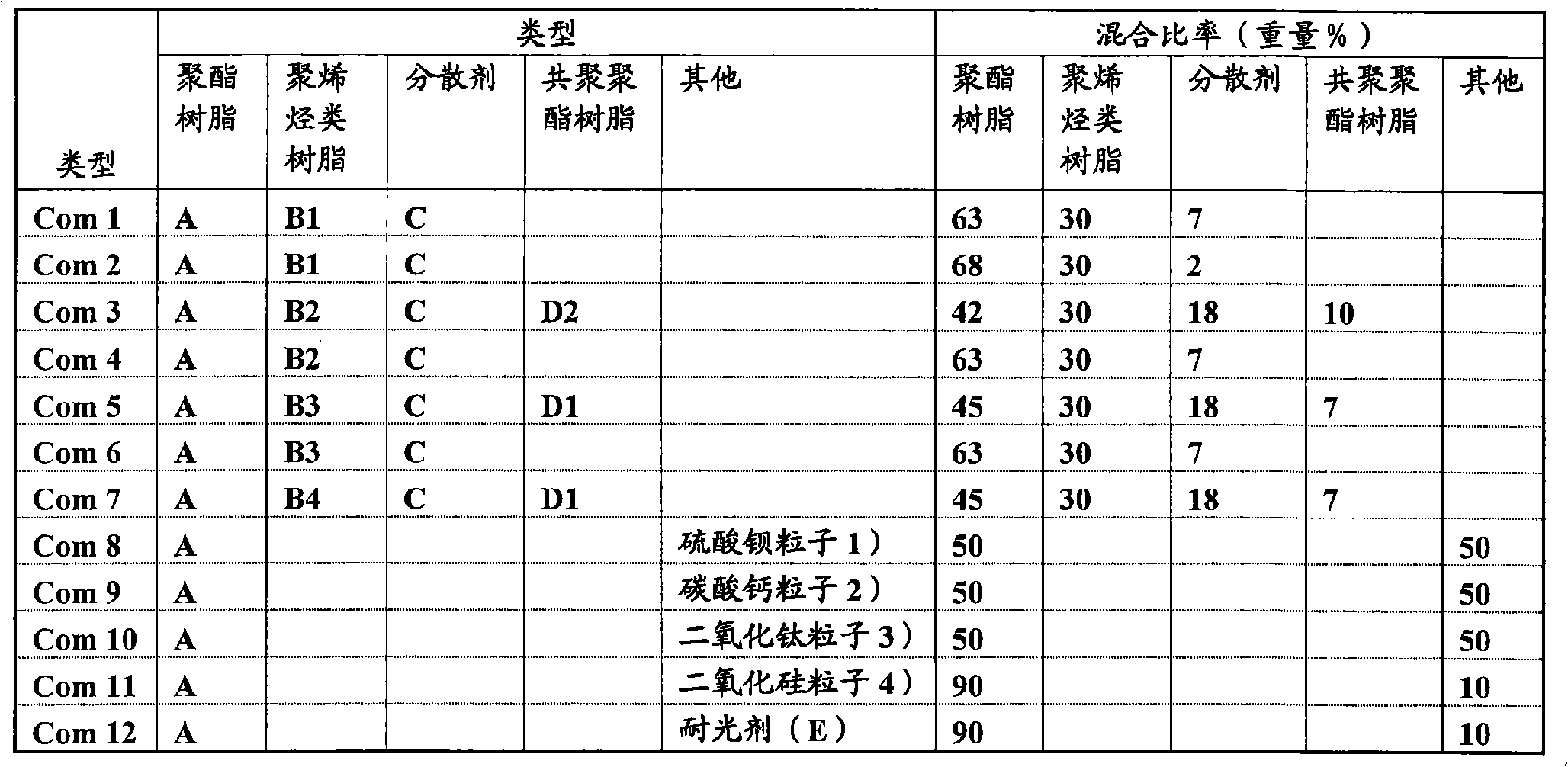

[0152] The polyester resin (A), masterbatch pellets (Com7), and masterbatch pellets (Com9), which were previously vacuum-dried at 160°C for 5 hours, were supplied to the extruder at a ratio of 41:43:16 in terms of weight (M) At the same time, the polyester resin (A) and masterbatch pellets (Com9) which were previously vacuum-dried at a temperature of 160°C for 5 hours were supplied to the extruder (S) at a ratio of 92:8 in terms of weight, After melt-extruding at a temperature of 280°C, foreign matter was filtered using a filter with a cut-off diameter of 30 μm, and then introduced into a T-die composite die. In addition, at this time, in the T-die compound die, the extruder (M) sends the resin to the inner layer of the film, and the extruder (S) sends the resin to the two outer layers of the film equally, so that Merged and extruded to form a 3-layer structure, co-extruded into a sheet form to form a molten laminated sheet, and this molten laminated sheet was bonded to a cyli...

Embodiment 2~3、 comparative example 1~3、5~7

[0155] The weight conversion ratio described in Table 1 and Table 2 was used to obtain a white film in the same manner as in Example 1. The resin ratios, thickness ratios, amounts of various additives, and physical properties and effects of the obtained films are shown in Tables 2 and 3. In addition, the film thickness of Example 2 was 225 μm.

Embodiment 4

[0157] Except having formed the 2-layer structure of A layer and B layer, it carried out similarly to Example 1, and obtained the film of 188 micrometers thickness. The resin ratios, thickness ratios, amounts of various additives, and physical properties and effects of the obtained films are shown in Tables 2 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com