Double effect process rectification diaminotoluene separation method

A technology of diaminotoluene and a separation method is applied in the field of separation of diaminotoluene by double-effect process rectification, which can solve the problems of increased tower heat load, large energy consumption, multi-high pressure steam, etc. The effect of reducing the heat load of the tower and reducing the difficulty of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

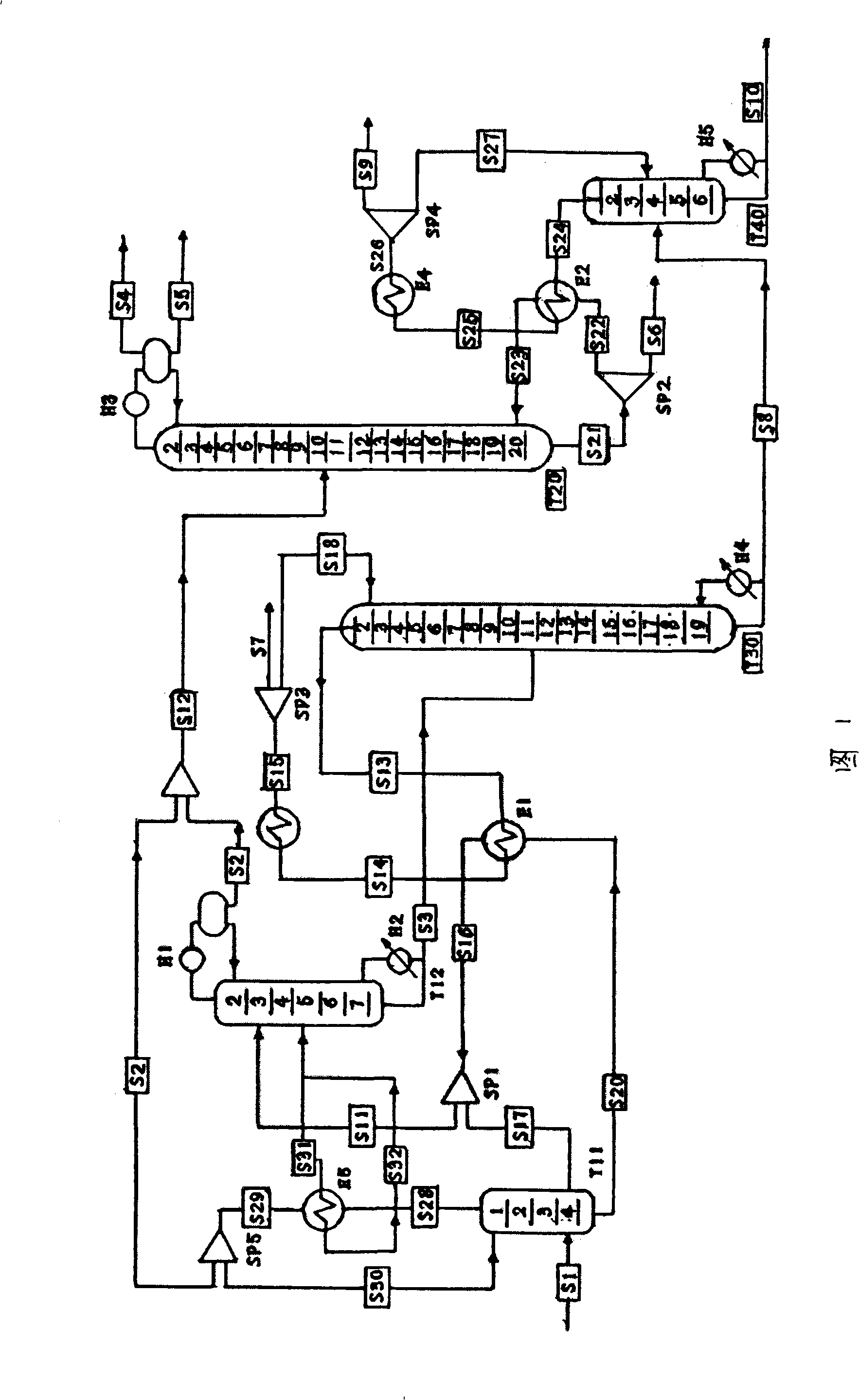

[0008] The present invention is characterized in that the crude TDA material containing water, solvent and tar is first dehydrated, then the solvent is removed, and then the TDA containing tar is subjected to isomer separation to remove ortho-position TDA and meta-position TDA, and finally obtain pure TDA, the solvent can be recycled.

[0009] As shown in Figure 1, concrete steps of the present invention are: the thick TDA material that contains water, solvent and tar enters dehydration tower (T11) dehydration from the bottom of the tower, then, part material directly enters desolventization tower (T20) from tower top, Most of the remaining materials are separated from the bottom of the tower through the dehydration tower (T12), and then the materials containing TDA and tar are discharged from the bottom of the tower, and then enter the first isomer separation tower (T30). (T30) tower top removes ortho-position TDA, then, the material containing a small amount of residue and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com