Method for coproduction of chrome tanning agent and menadione

A technology of menadione and chrome tanning agent, which is applied in the field of co-production of menadione with chrome tanning agent, can solve the problems of difficult expansion of output and large one-time investment, and achieve low production cost, reduction of waste liquid discharge, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

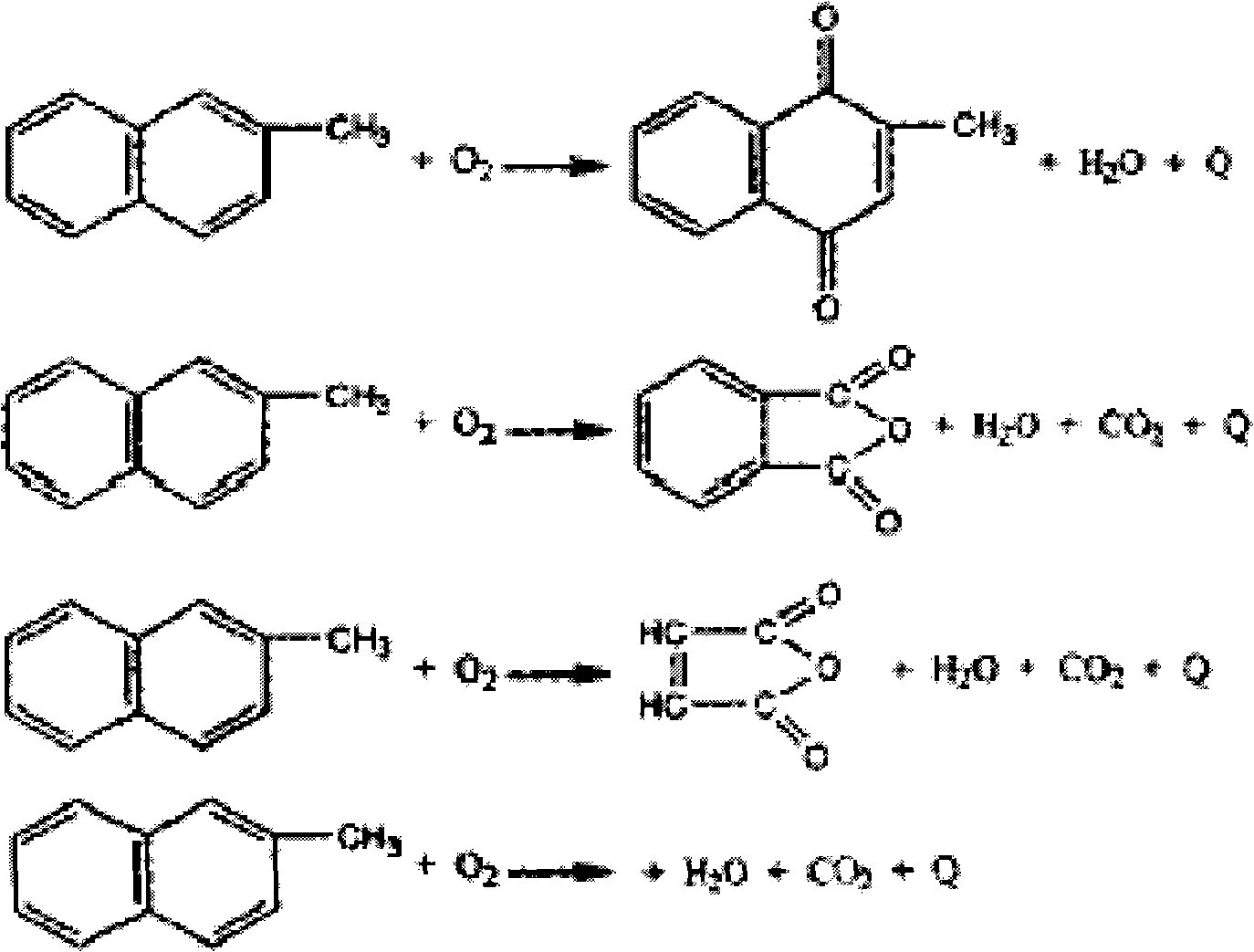

Method used

Image

Examples

Embodiment 1

[0027] The preparation process is as follows:

[0028] ① Preparation of Menadione

[0029] Add 10g of methylnaphthalene (content>95%), 35g of water and 0.35g of EL series emulsifier into a 500ml reaction flask, and stir and mix fully at 40°C. In addition, add 40g of sodium red alum (content > 98%) and 85ml of water into another 500ml reaction bottle, slowly add 60g of concentrated sulfuric acid under the condition of stirring and cooling down, and cool down to 40°C to get "red liquid" for use; The solution was slowly added dropwise to the first reaction bottle under stirring conditions, and the temperature was kept at 48°C. After the drop, the temperature was slowly raised to 70°C for 0.5 hours, and then the temperature was lowered to 45°C, filtered and dried to obtain a bright yellow crystalline powder. 6.5g, assay content 91.1%, yield 48%.

[0030] ② Preparation of basic chromium sulfate

[0031] Get preparation menaquinone gained mother liquor 200ml and measure unreacted...

Embodiment 2

[0033] The preparation process is as follows:

[0034](1) Preparation of menadione: Add 10g of methylnaphthalene, 55g of water and 0.38g of EL series emulsifier into a 500ml first reaction bottle, stir and mix thoroughly at 40°C; in addition, add 75g of sodium red alum and 110ml of water into 500ml of a second reaction In the bottle, slowly add 105 grams of 98% sulfuric acid under the condition of stirring and lowering the temperature, and cool down to 40°C to obtain the red liquid for use; then slowly add the prepared red liquid dropwise into the first reaction bottle under the condition of stirring, keeping The temperature was 43°C, slowly raised to 60°C after dropping, reacted for 0.5 hours, then cooled to 42°C, filtered and dried to obtain 7.5g of bright yellow crystalline menadione powder, assayed content 97.2%, yield 59%. ;

[0035] (2) The preparation of basic chromium sulfate: get the mother liquor 200ml that prepares menadione gained and record unreacted Na 2 Cr 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com