Omnidirectional running type forklift

A forklift and frame technology, which is applied in the field of omnidirectional traveling forklifts, can solve problems such as large auxiliary space, and achieve the effect of improving work efficiency and saving warehouse space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below through a preferred embodiment in conjunction with the accompanying drawings.

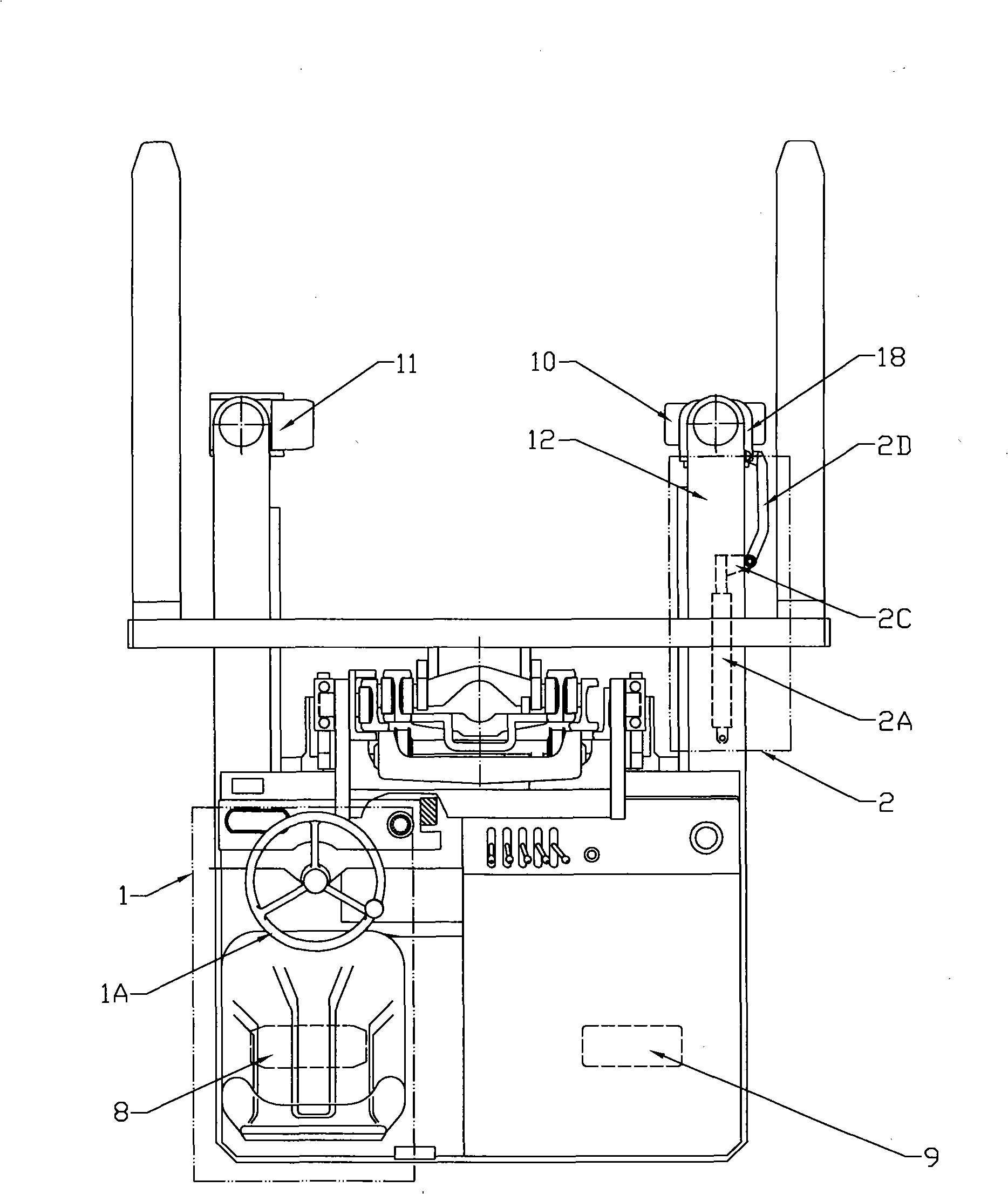

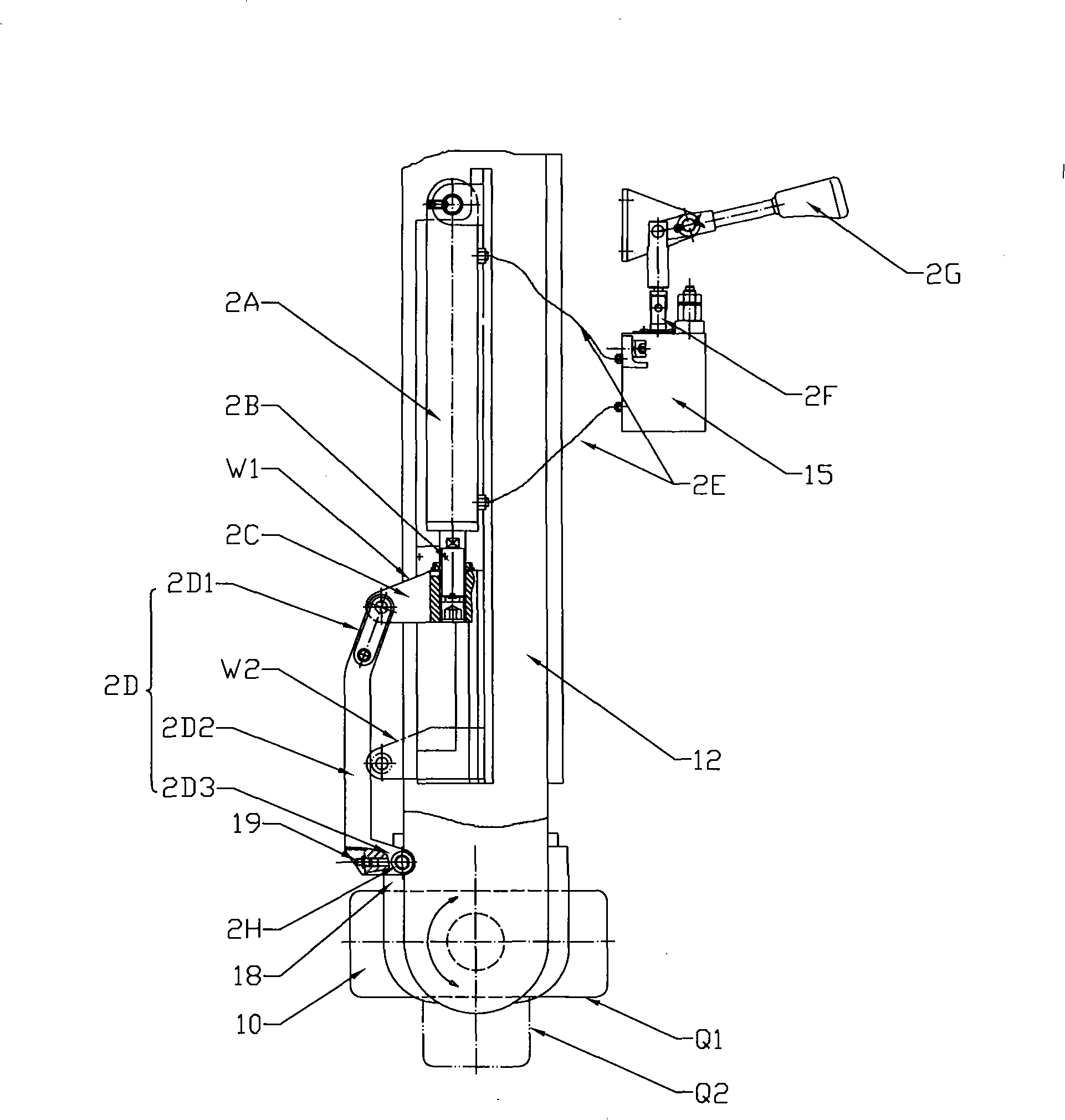

[0038] Such as figure 1 As shown, this omnidirectional travel type forklift comprises driving wheel 8, rear supporting wheel 9, front steering wheel 10, front supporting wheel 11 and driving wheel steering device 1, front wheel steering device 2, driving wheel-rear supporting wheel damping Suspension device 3, driving wheel position sensing device 4, wherein:

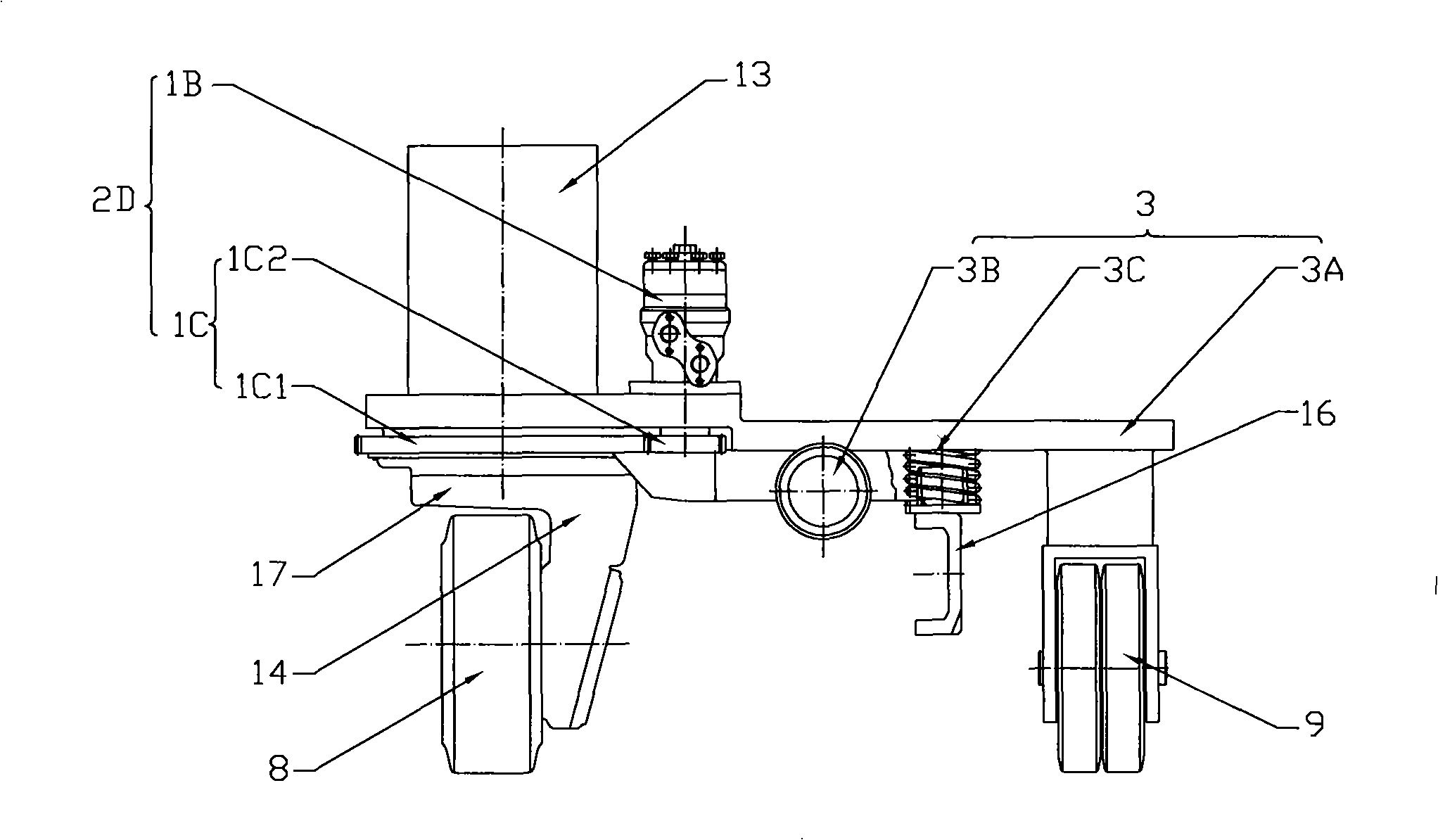

[0039] Drive wheel-rear support wheel shock absorbing suspension device 3 (see image 3 ) includes a swing frame 3A and a shock absorbing spring 3C, the swing frame 3A is connected to the frame 16 through a swing shaft 3B, the shock absorbing spring 3C is placed between the swing frame 3A and the frame 16, and the shock absorbing spring 3C is located on the rear support Between the wheel 9 and the swing shaft 3B. Drive wheel 8 (through its revolving body rotating shaft), rear su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com