Ceramic tile laminating apparatus

A technology for sticking devices and tiles, applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems of wear scars or fracturing on the surface of tiles, affecting the appearance and performance of tiles, restricting the efficiency of tile packaging, and preventing friction and extrusion. , Reduce the cost of packaging, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

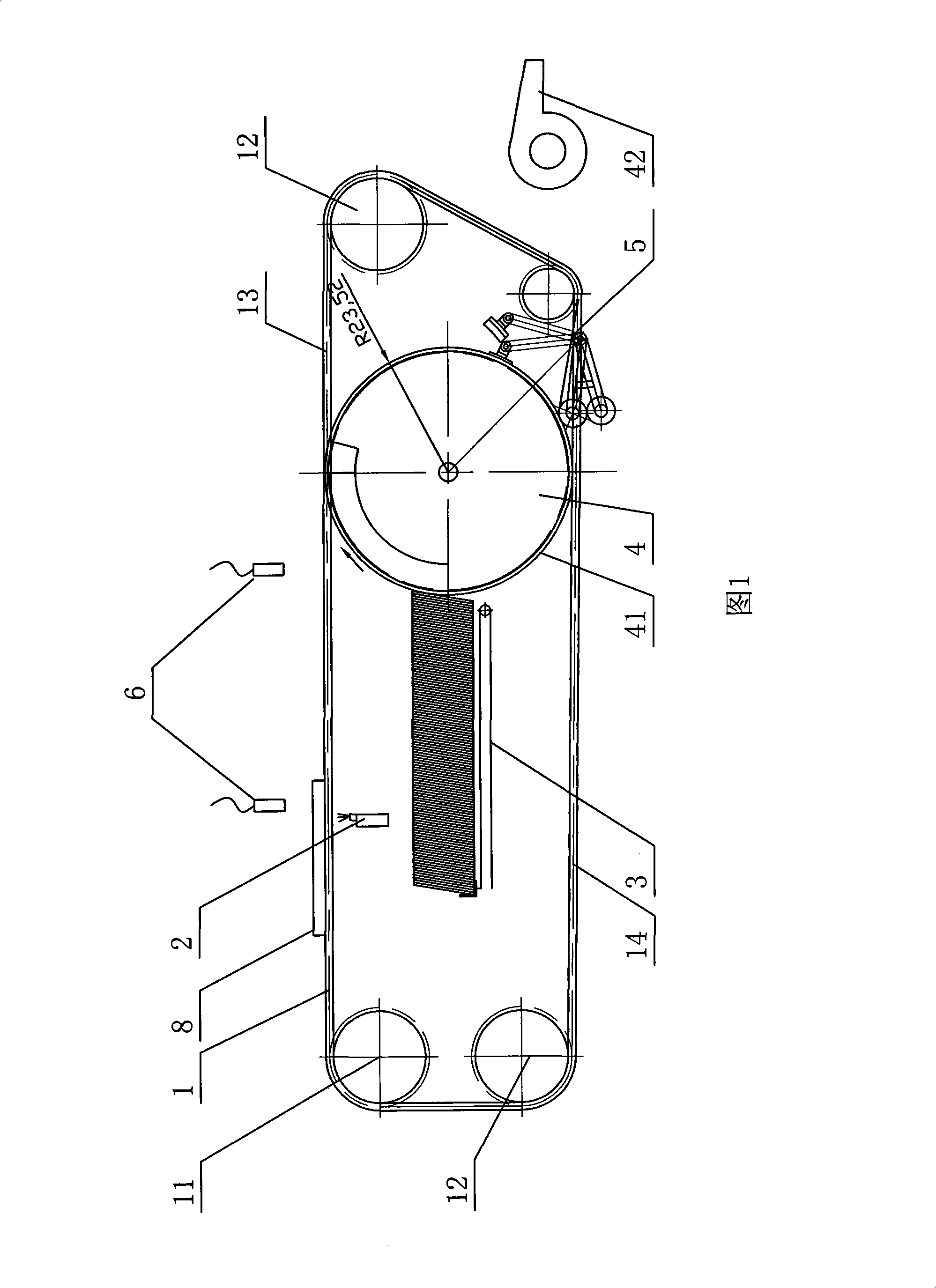

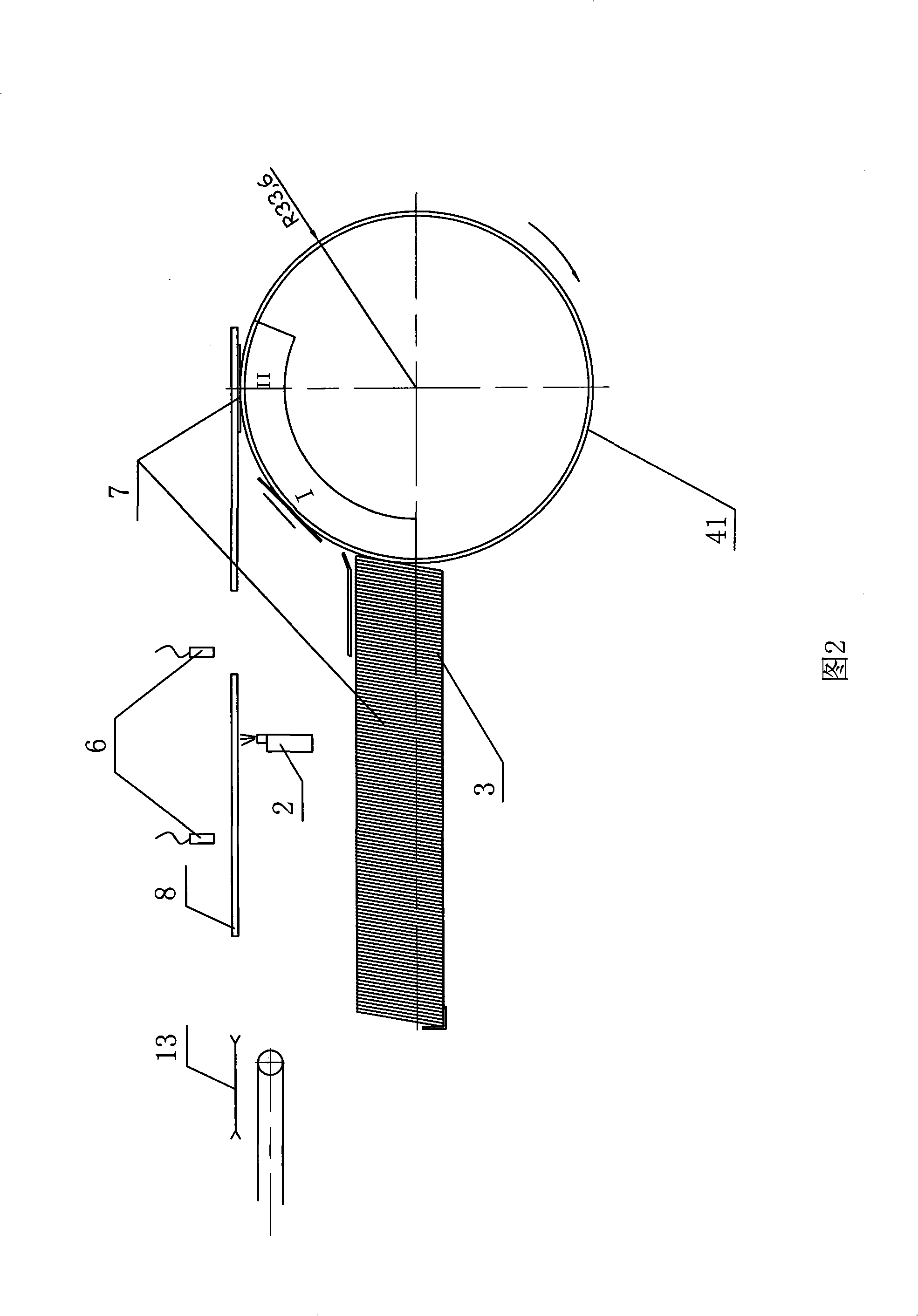

[0027] As shown in Fig. 1 and Fig. 2, a kind of tile sticking device of the present invention includes a tile conveying device 1, and the tile conveying device 1 consists of a driving wheel 11, three driven wheels 12, an upper conveyor belt 13, and a lower conveyor belt 14. and conveyor belts on both sides. In addition, the tile pasting device also includes a glue spraying device 2 , a release paper conveying device 3 , a release paper pasting device 4 , and a braking device 5 for braking the release paper pasting device 4 . Described glue spraying device 2 is located at the position below the upper conveyor belt 13 on the front side of release paper pasting device 4. This glue spraying device 2 is specifically a glue spraying head, and there are two glue spraying heads, which are arranged in parallel and correspond to each other. Place it under the tile 8 where stickers are needed. Usually, in order to save the amount of release paper 7 used, the bottom of the tile needs stic...

Embodiment 2

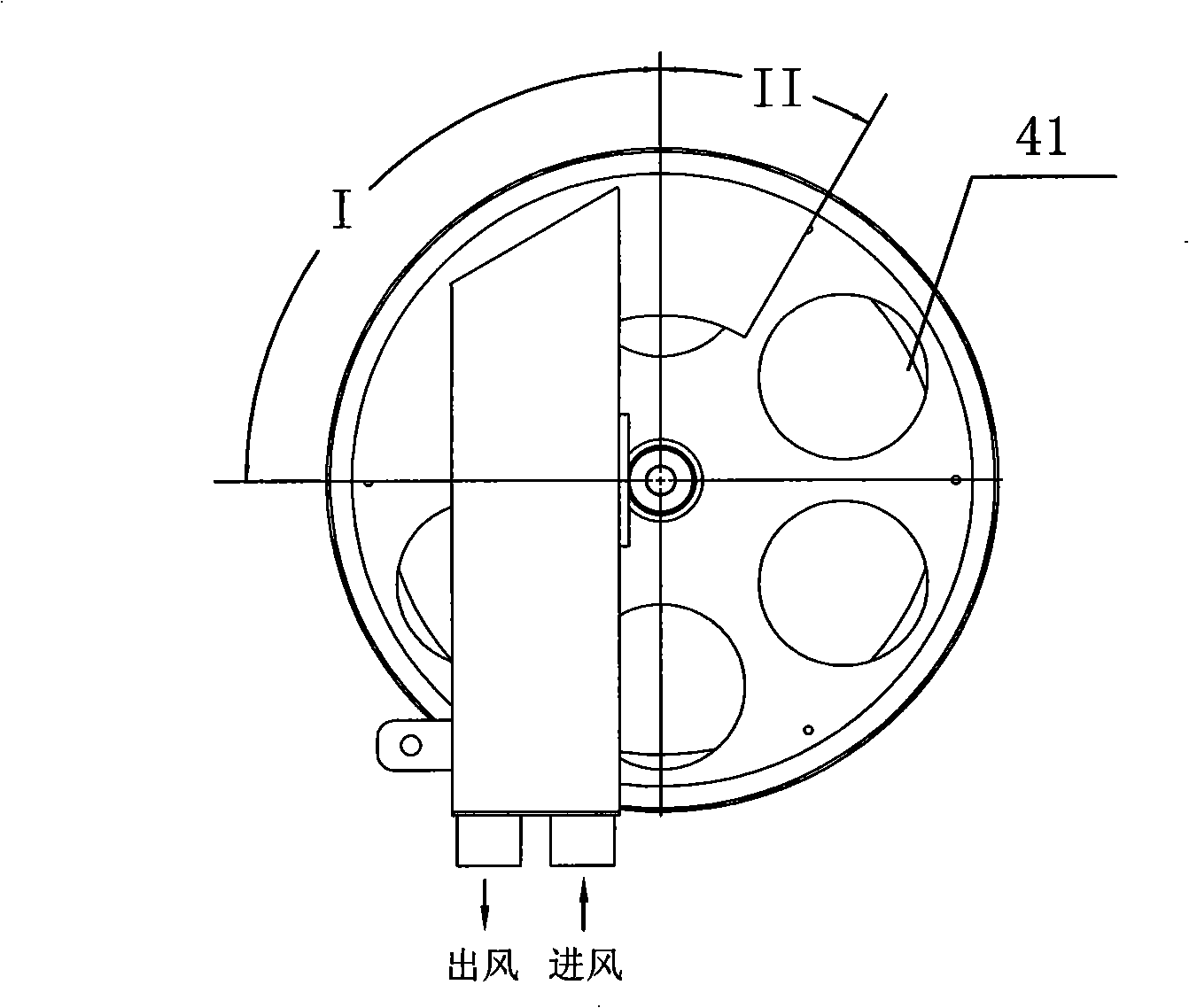

[0034] As shown in Figure 6, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the mesh structure on the wall surface of the horizontal drum 41 is partially provided, and the mesh structure is correspondingly arranged inside the horizontal drum 41 Negative pressure zone I and positive pressure zone II. Using the local arrangement of the mesh structure, the positive pressure and negative pressure in the horizontal drum 41 can be effectively gathered, so that the pressure of absorbing the release paper 7 and blowing out the release paper 7 is greater, even if the release paper 7 follows the horizontal drum. At 41 o'clock, it can be tightly adsorbed, and when blowing out, the release paper 7 is tightly pasted on the bottom surface of the ceramic tile 8 by a larger blowing force, and the pasting effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com