Method for preparing Ag nano granule compound CoSb3-based pyroelectric material

A technology of thermoelectric materials and nanoparticles, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems that nanoparticles are not easy to disperse, and achieve simple and easy preparation methods and excellent thermoelectricity. The effect of increasing the value and decreasing the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: AgNO 3 Dissolved in ethanol to prepare AgNO with a molar concentration of 0.01mol / L 3 ethanol solution, 4.3g of doped CoSb 3 The mechanically alloyed powder (particle size3 Ethanol solution 0.4ml. The completed solution is dripped into and dried into the pre-sintered body, and then put into the spark plasma sintering equipment for sintering. The sintering temperature is 450° C., the holding time is 8 minutes, the sintering pressure is 30 MPa, and the heating rate is 100° C. / min. Finally get Ag and CoSb 3 The composite material with a molar ratio of 0.0004:1 has a density of about 93%. The room temperature resistivity and Seebeck coefficient of the composite material are 12.4μΩm and -146μV / K, respectively.

Embodiment 2

[0026] Example 2: AgNO 3 Dissolved in ethanol to prepare AgNO with a molar concentration of 0.05mol / L 3 ethanol solution, 4.3g of doped CoSb 3 The base thermoelectric material mechanically alloyed powder (particle size 3 Ethanol solution 0.4ml. The completed solution is dripped into and dried into the pre-sintered body, and then put into the spark plasma sintering equipment for sintering. The sintering temperature is 450° C., the holding time is 3 minutes, the sintering pressure is 70 MPa, and the heating rate is 100° C. / min. Finally get Ag and CoSb 3 The composite material with a molar ratio of 0.002:1 has a density of about 92%. The room temperature resistivity and Seebeck coefficient of the composite material are 12.2μΩm and -146μV / K, respectively.

Embodiment 3

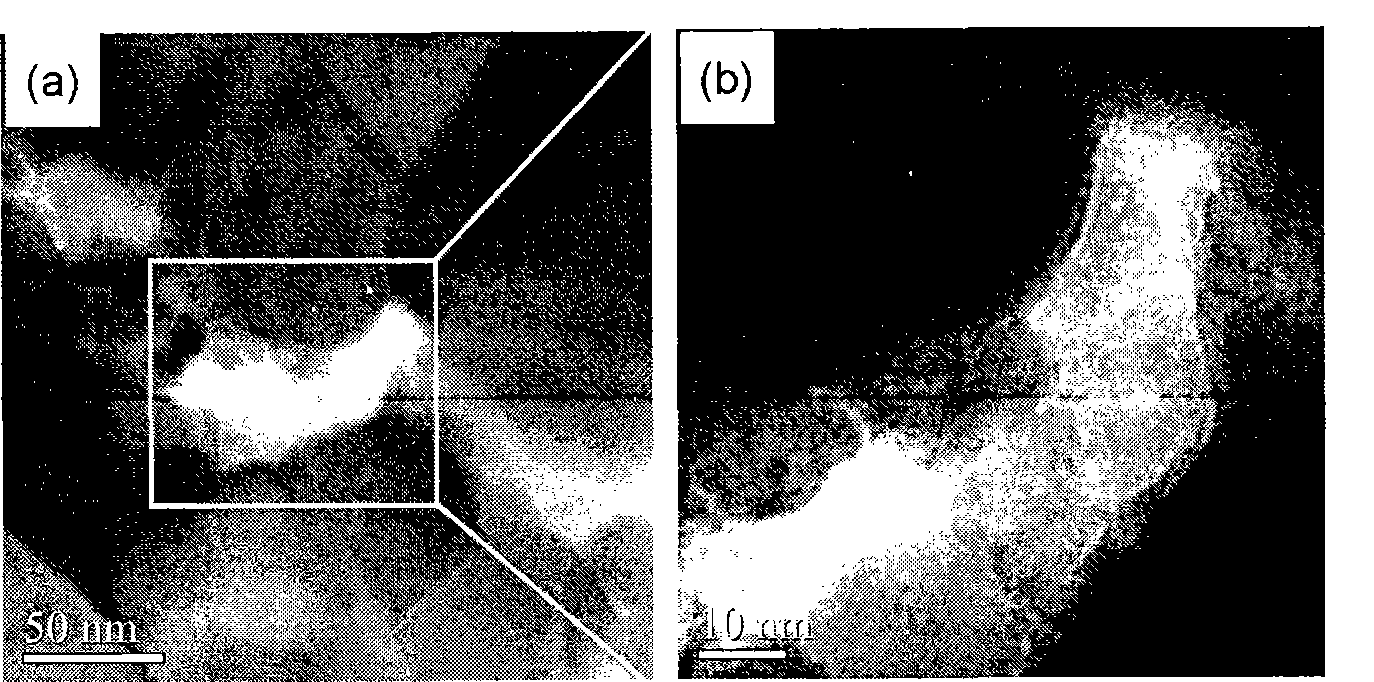

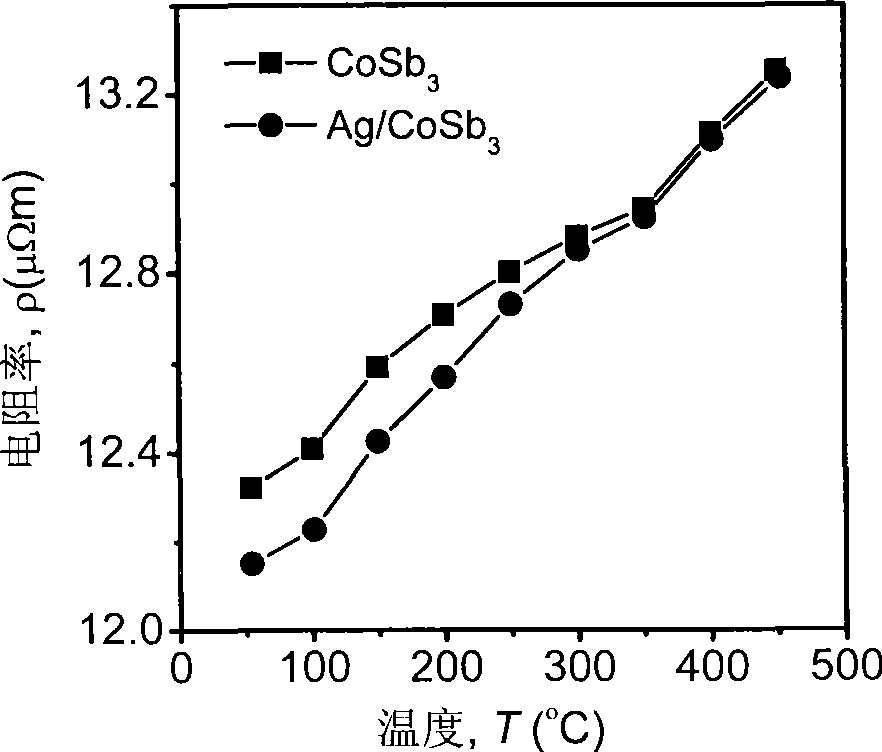

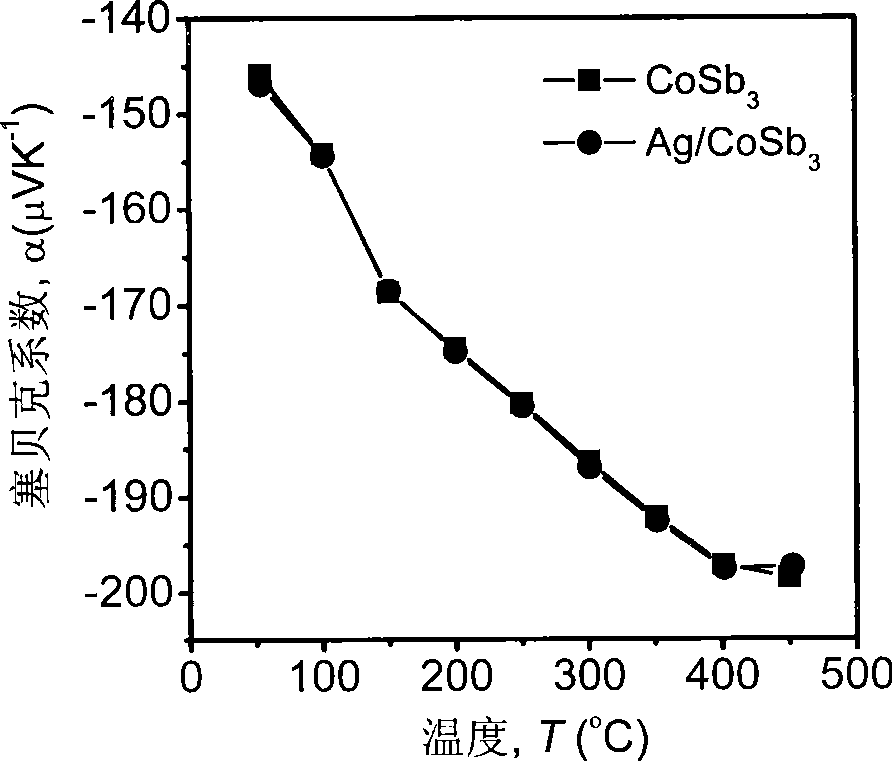

[0027] Example 3: AgNO 3 Dissolve in ethanol to prepare AgNO with a molar concentration of 0.1mol / L 3 ethanol solution, 4.3g of doped CoSb 3 The base thermoelectric material mechanically alloyed powder (particle size 3 Ethanol solution 0.4ml. The completed solution is dripped into and dried into the pre-sintered body, and then put into the spark plasma sintering equipment for sintering. The sintering temperature is 450° C., the holding time is 5 minutes, the sintering pressure is 50 MPa, and the heating rate is 100° C. / min. Finally get Ag and CoSb 3 The composite material with a molar ratio of 0.004:1 has a density of about 94%. figure 1 It is the TEM photo of the composite composite material. From the figure we can see that the CoSb 3 The grain size of the matrix is ~100 nm, while the size of the Ag particles located in the inter-grain space is about 10-20 nm. figure 2 , image 3 with Figure 4 Ag / CoSb were compared separately 3 Composite and pure CoSb 3 The res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com