Flame retardant thermoplastic resin composition

A composition and resin technology, applied in the field of flame retardant polymer compositions, can solve problems such as deformation and physical property changes, limiting applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0106] Components (A)-(D) were mixed as shown in Table 1 and Table 2, and each mixture was extruded in the form of pellets at 180-250° C. using a conventional twin-screw extruder. The resin pellets were dried at 80°C for 3 hours, and molded into test samples with a 6oz injection molding machine at 180-280°C, and the mold temperature was 40-80°C. The flame retardancy and physical properties of the test samples were evaluated according to the following procedures.

[0107] The flame retardancy of the test samples was determined according to UL 94VB with thicknesses of 1 / 12" and 1 / 8". The notched Izod impact strength (kgf·cm / cm) of the test specimens was measured at 23° C. according to ASTM 256A with a thickness of 1 / 8″. The heat resistance was measured under a load of 5 kgf according to ASTM D 1525.

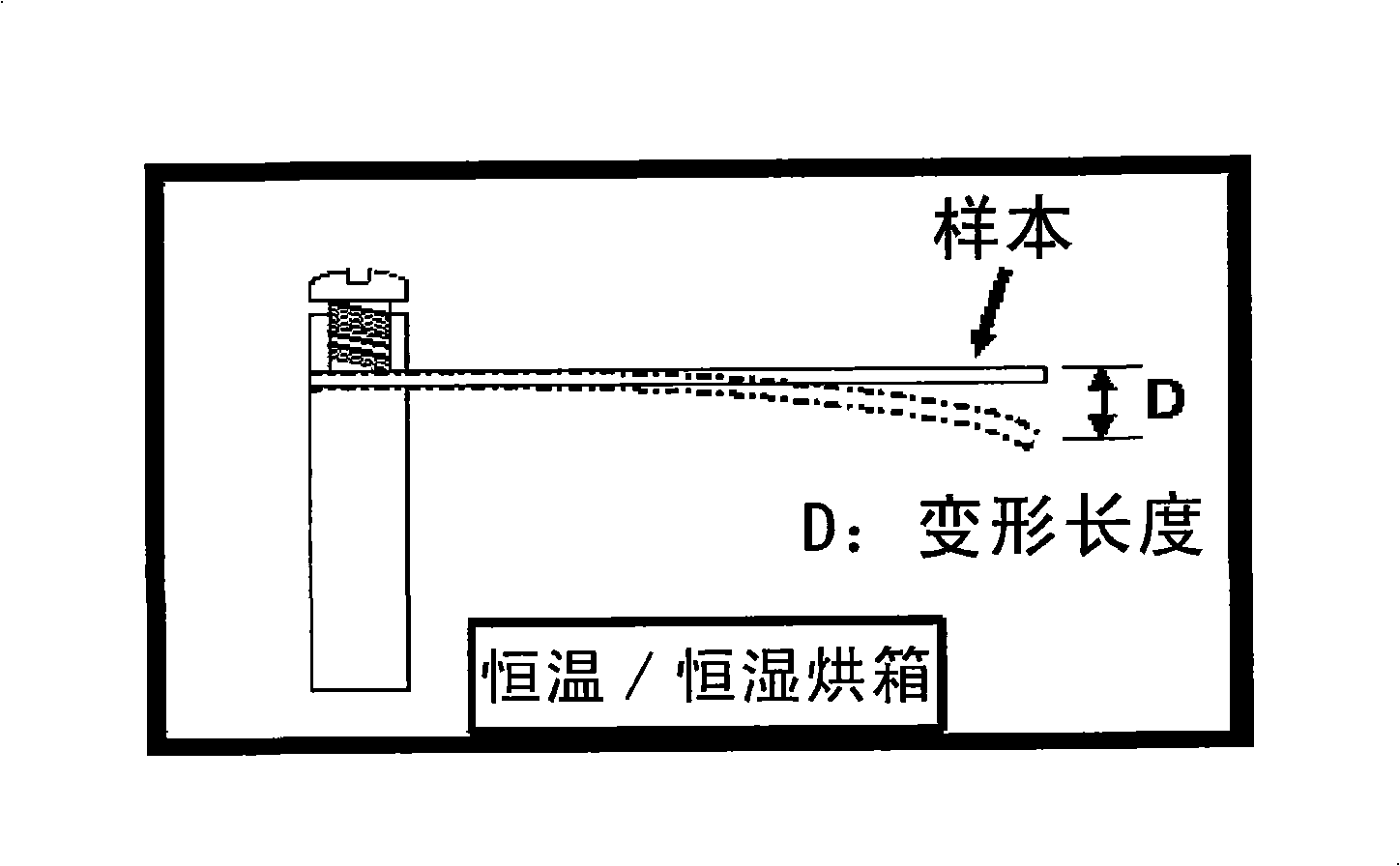

[0108] For a sample whose size is 125mm (width) x 13mm (length) x 1.6mm (thickness), its moisture absorption and heat sagging are measured. The moisture absorption rate was measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com