Magnetic inorganic hollow compound microsphere and preparation method thereof

A composite microsphere and hollow technology, which can be used in inorganic pigment processing, inorganic material magnetism, chemical instruments and methods, etc., can solve the problems of time-consuming, high polyelectrolyte price, and difficulty in large-scale synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) 0.2g superparamagnetic Fe of 10nm 3 O 4 Nanoparticles were ultrasonically dispersed into 20ml of 2M HNO 3 The magnetic nanoparticles were pretreated in the solution for 2 min, and the magnetic nanoparticles were fully washed with deionized water, and then ultrasonically dispersed into a mixed solution of 4.4 g of sodium citrate and 20 ml of deionized water. Finally, the product was separated with a magnet and dispersed in 5 ml of deionized water to obtain a stable dispersion for use.

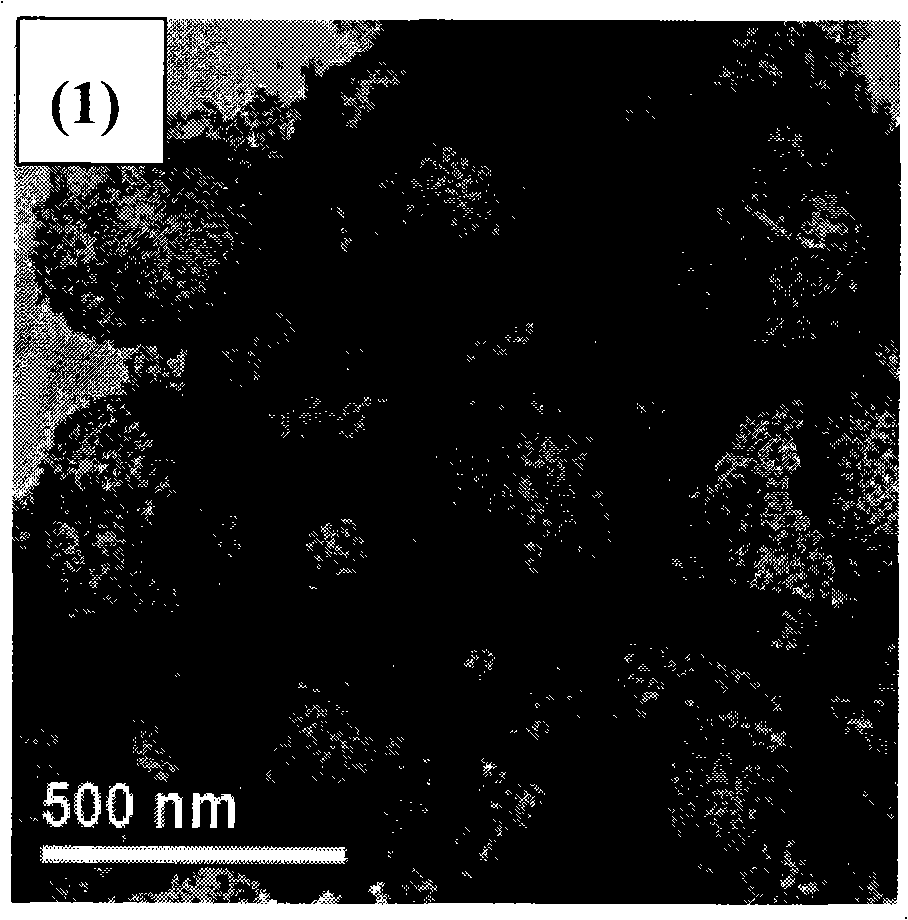

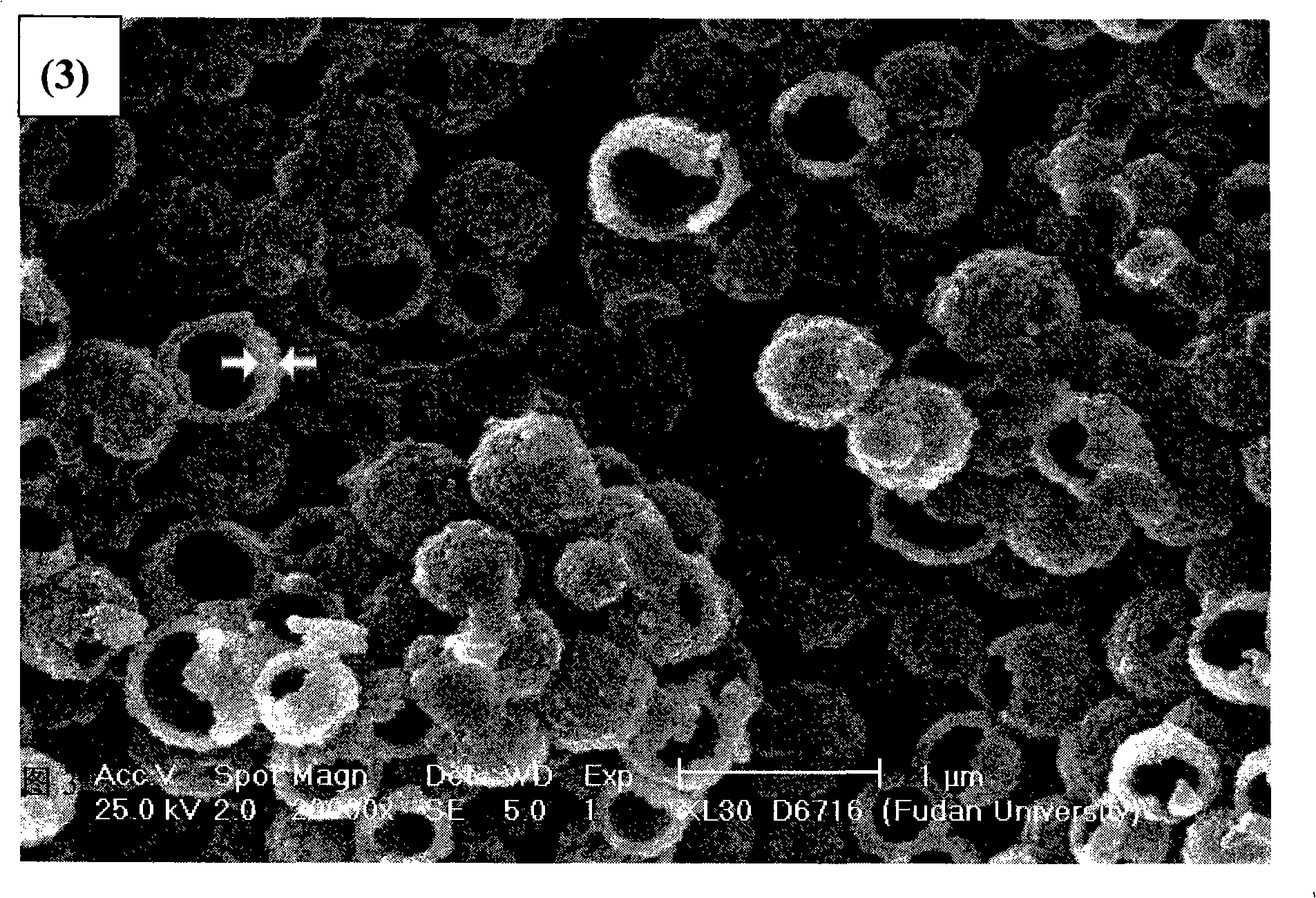

[0018] (2) Disperse 10g of 1μm polystyrene microspheres into 300g of deionized water, then take 5g of this solution and mix with the above nanoparticle solution, and then put the mixed solution into a 35°C oven to dry. The solid obtained after drying was immersed in a mixed solution of 0.9 g of ethyl orthosilicate, 0.1 g of 2M HCl, 8 g of ethanol and 2 g of deionized water for 3 hours, and then taken out to dry. After repeating the above procedure 3 times, the obtained solid was pl...

Embodiment 2

[0020] (1) 0.2g superparamagnetic γ-Fe of 10nm 2 O 3 The nanoparticles were ultrasonically dispersed into 20 ml of 1M HCl solution for 1 min for pretreatment, and the magnetic nanoparticles were fully washed with deionized water, and then re-sonicated into a mixed solution of 4.4 g of sodium citrate and 20 ml of deionized water. Finally, the product was separated with a magnet and dispersed in 5 ml of deionized water to obtain a stable dispersion for use.

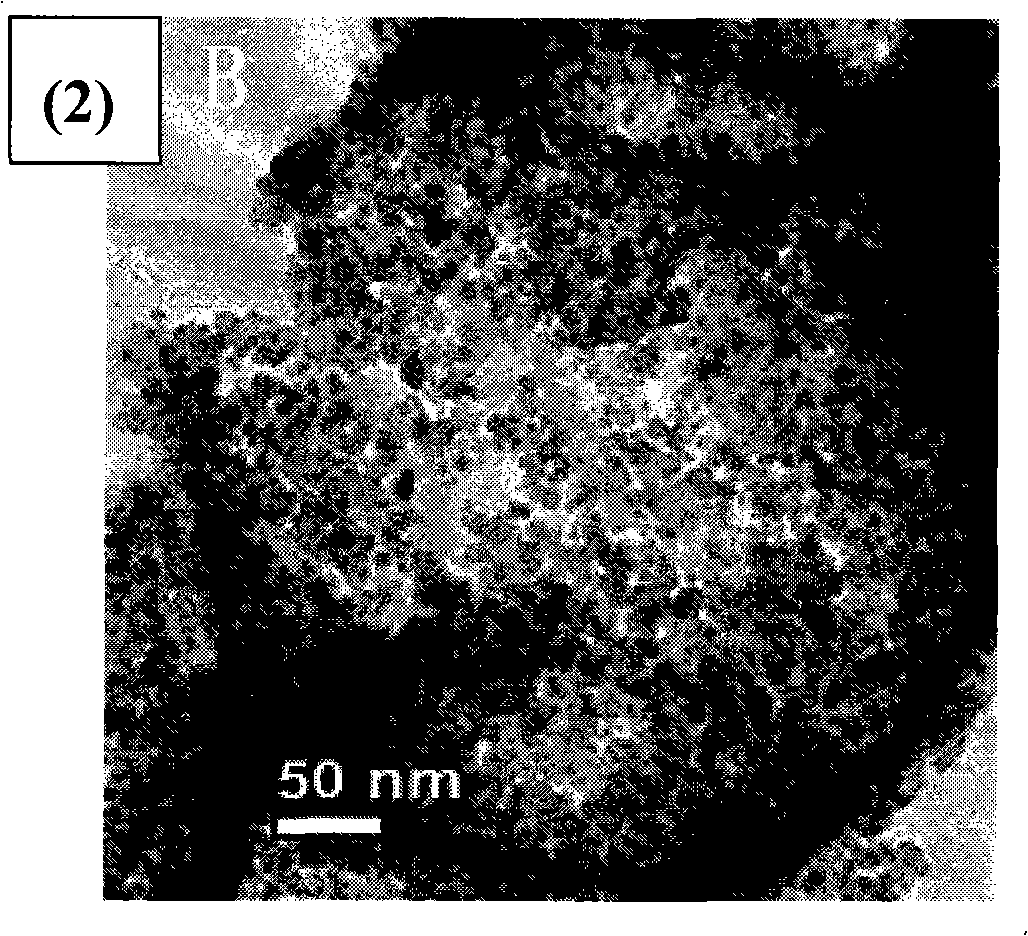

[0021] (2) 30g of 100nm polymethyl methacrylate microspheres were dispersed into 300g of deionized water, then 20g of this solution was mixed with the above-mentioned nanoparticle solution, and then the mixed solution was put into a 50° C. oven for drying. The solid obtained after drying was immersed in a mixed solution of 1.5 g of ethyl orthosilicate, 0.5 g of 2M HCl, 15 g of ethanol and 5 g of deionized water for 3 h. Remove to dry. After repeating the above steps 5 times, the obtained solid was placed in a 5 ml crucib...

Embodiment 3

[0023] (1) Ultrasonic dispersion of 0.4 g of superparamagnetic 20 nm cobalt nanoparticles into 30 mL of 2M HNO 3 The magnetic nanoparticles were pretreated in the solution for 5 min, and the magnetic nanoparticles were fully washed with deionized water, and then ultrasonically dispersed into a mixed solution of 5.0 g of sodium citrate and 30 ml of deionized water. Finally, the product was separated with a magnet and dispersed in 5 ml of deionized water to obtain a stable dispersion for use.

[0024] (2) 8g of 380nm poly(methyl methacrylate-methacrylic acid) copolymerized microspheres were dispersed in 200g of deionized water, then 5g of this solution was mixed with the above-mentioned nanoparticle solution, and then the mixed solution was put into a 45°C oven Dry in medium. The solid obtained after drying was immersed in a mixed solution of 1.8 g of zirconium isopropoxide, 0.4 g of 2M HCl, 8 g of ethanol and 6 g of deionized water for 5 h. Remove to dry. After repeating the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com