Bleaching and dyeing control technology and its control device

A control technology and bleaching and dyeing technology, applied in the field of bleaching and dyeing, which can solve the problems of uneven dyeing of fabrics or yarns, high labor intensity, and poor levelness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

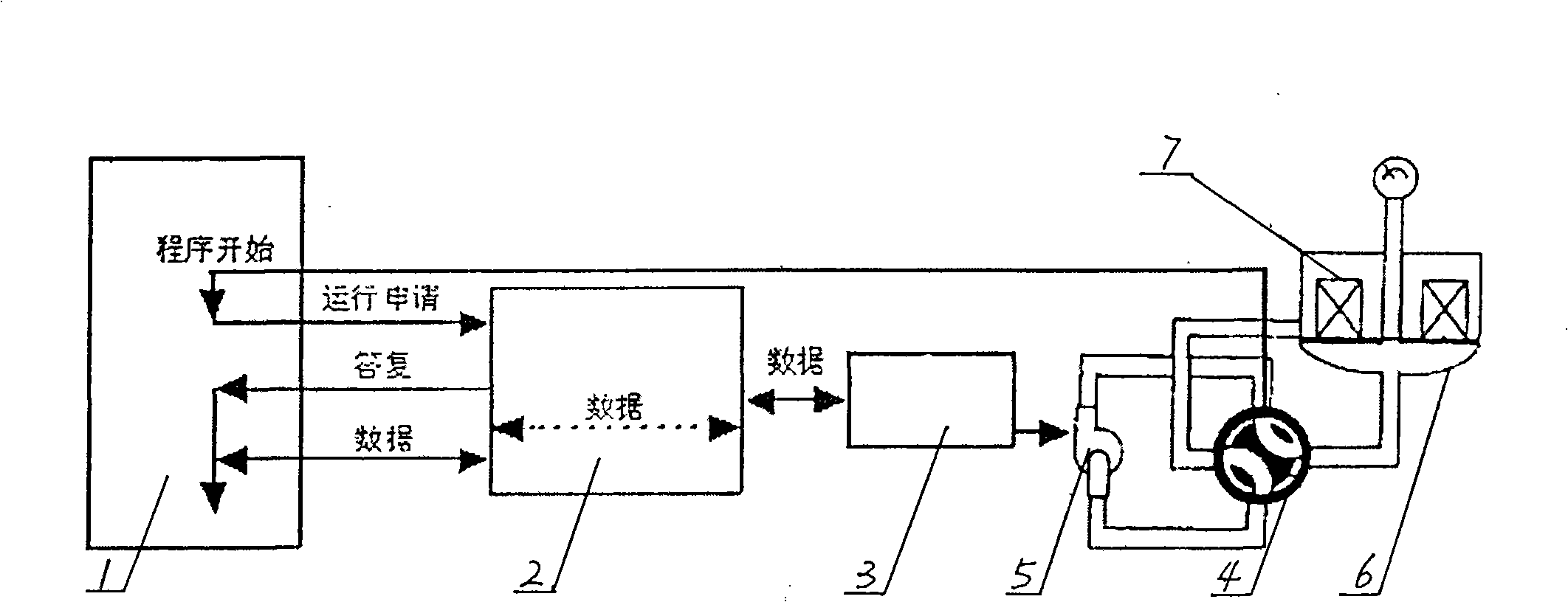

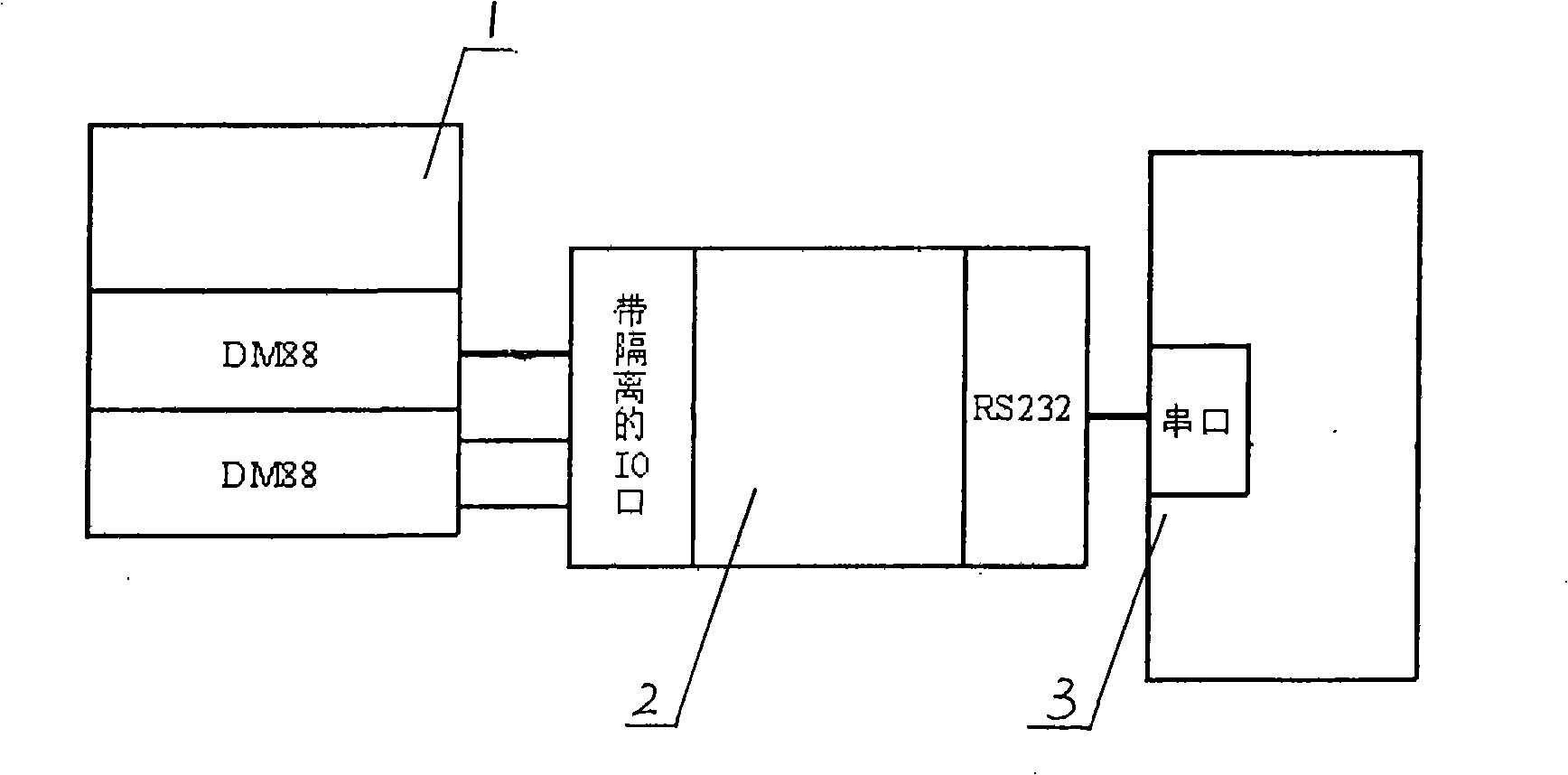

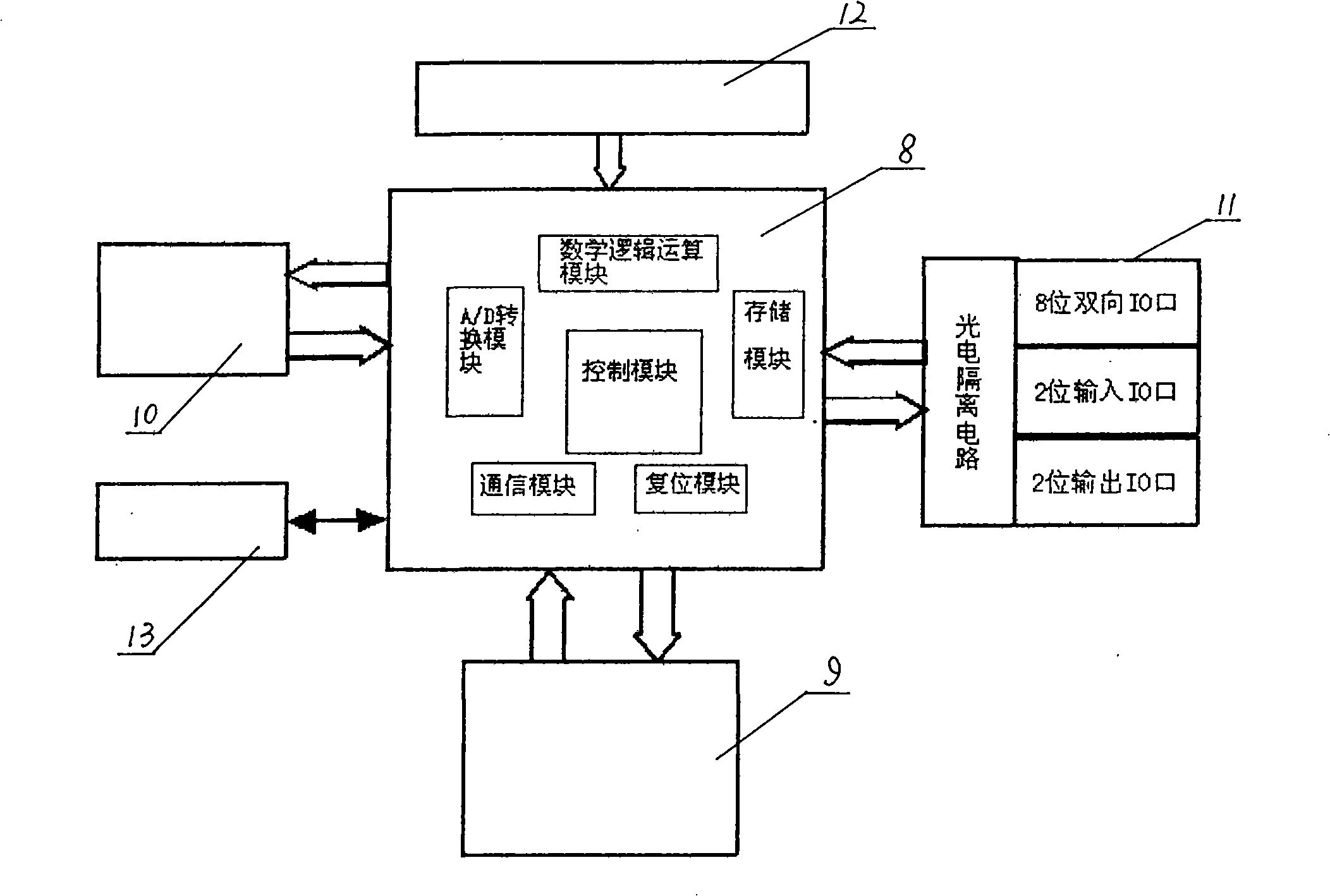

[0030] The structure of the bleaching and dyeing control device is as follows: figure 1 As shown, it includes dyeing computer 1, dyeing equipment controller 2, pulse flow converter 3, and flow direction regulator 4. Dyeing computer 1 adopts GFC883, dyeing computer 1 transmits data to dyeing equipment controller 2, and according to dyeing equipment controller 2 The instruction controls the flow direction regulator 4 to automatically change direction; the dyeing equipment controller 2 is respectively connected with the dyeing computer 1 and the pulse flow frequency converter 3, and the dyeing equipment controller 2 receives the data transmitted by the dyeing computer 1 and performs mathematical and logical operations to convert The data is sent to the dyeing computer 1, and the dyeing computer 1 controls the automatic reversing of the flow regulator 4; at the same time, the dyeing equipment controller 2 calculates the pulse flow data according to the set formula, and sends it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com