ABS testing bench control system based on CAN bus

A technology of CAN bus and measurement and control system, which is applied in the field of ABS test bench measurement and control system, can solve the problems of low precision, long cycle, high experiment cost, etc., and achieve the effect of improving reliability, reducing risk and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

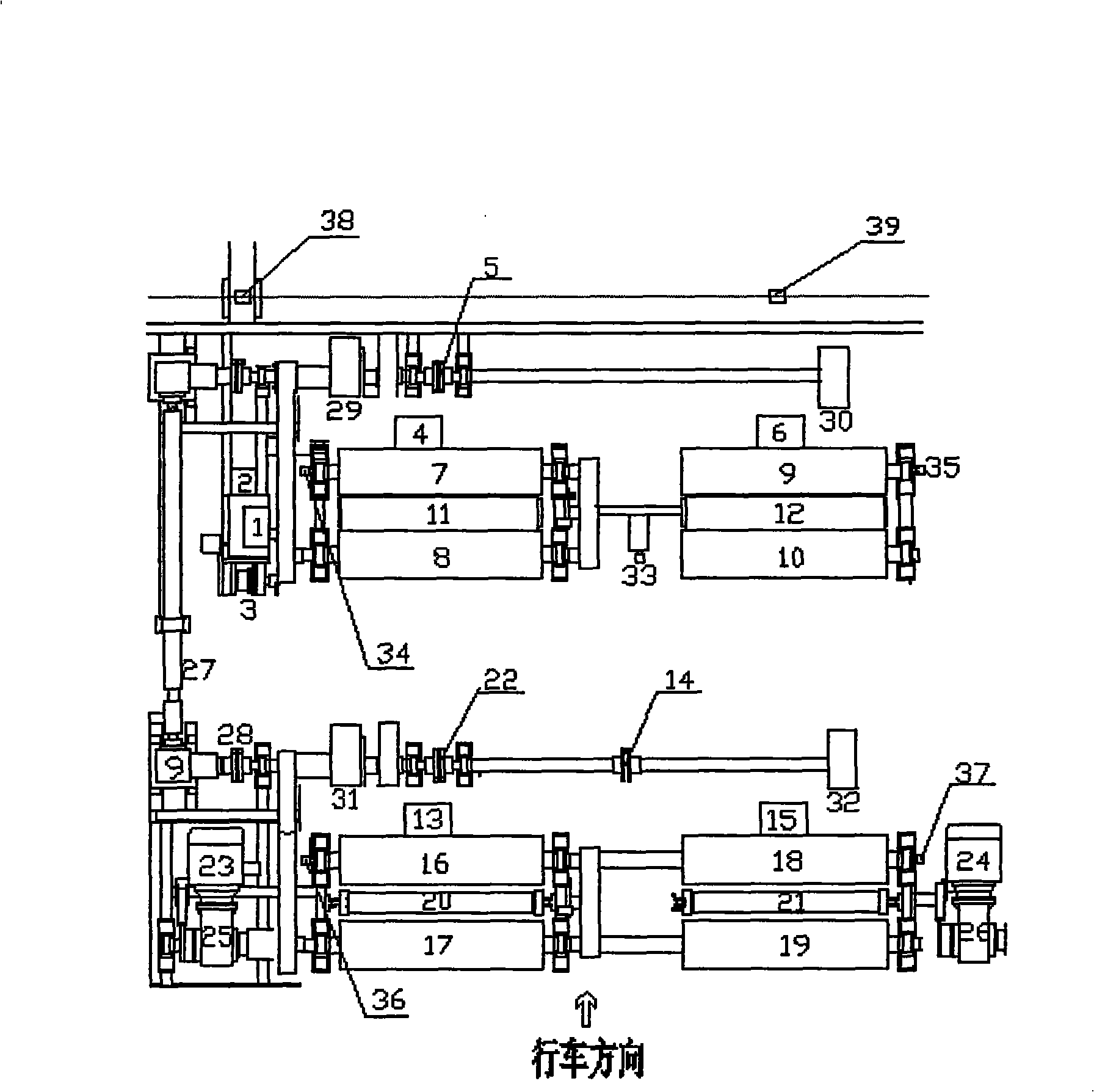

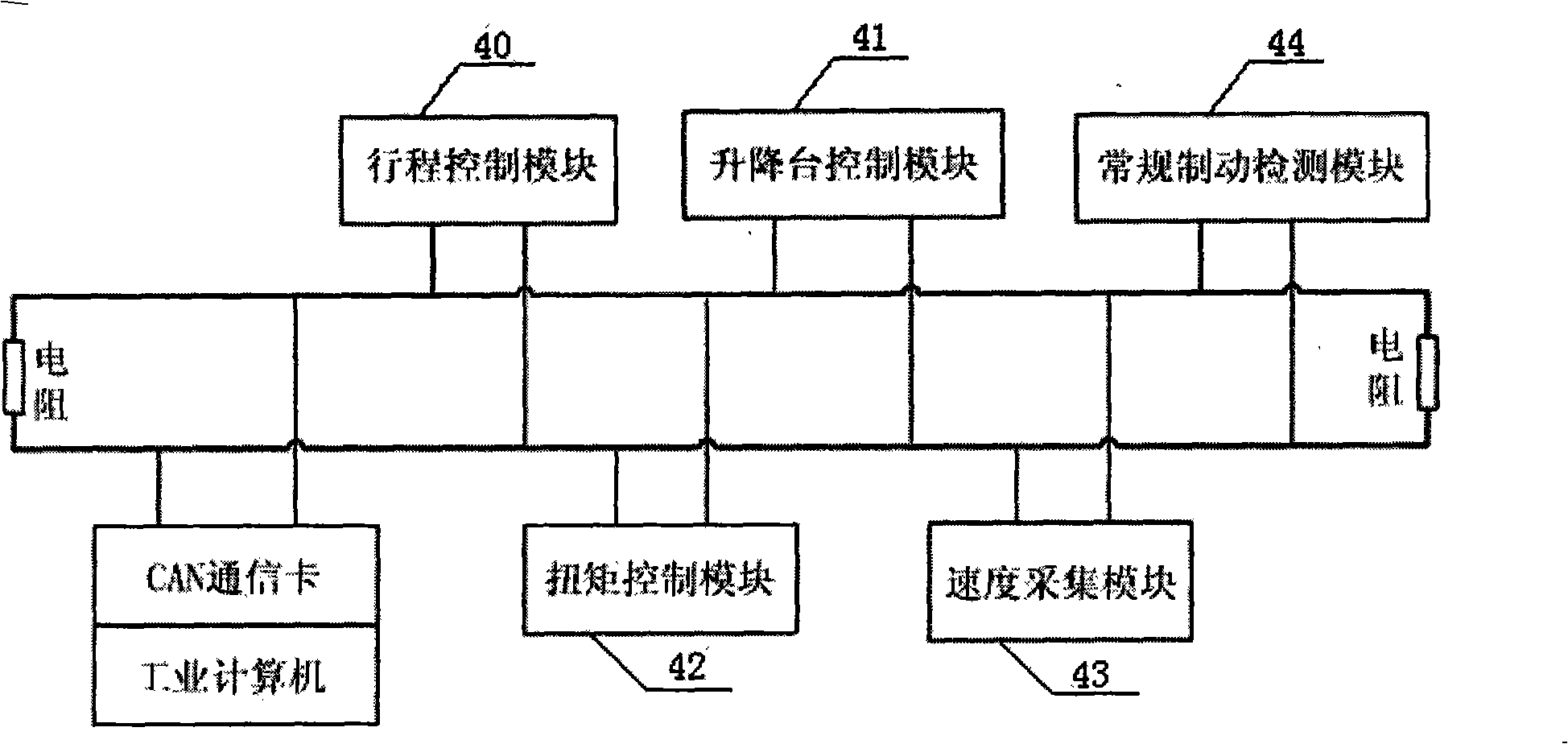

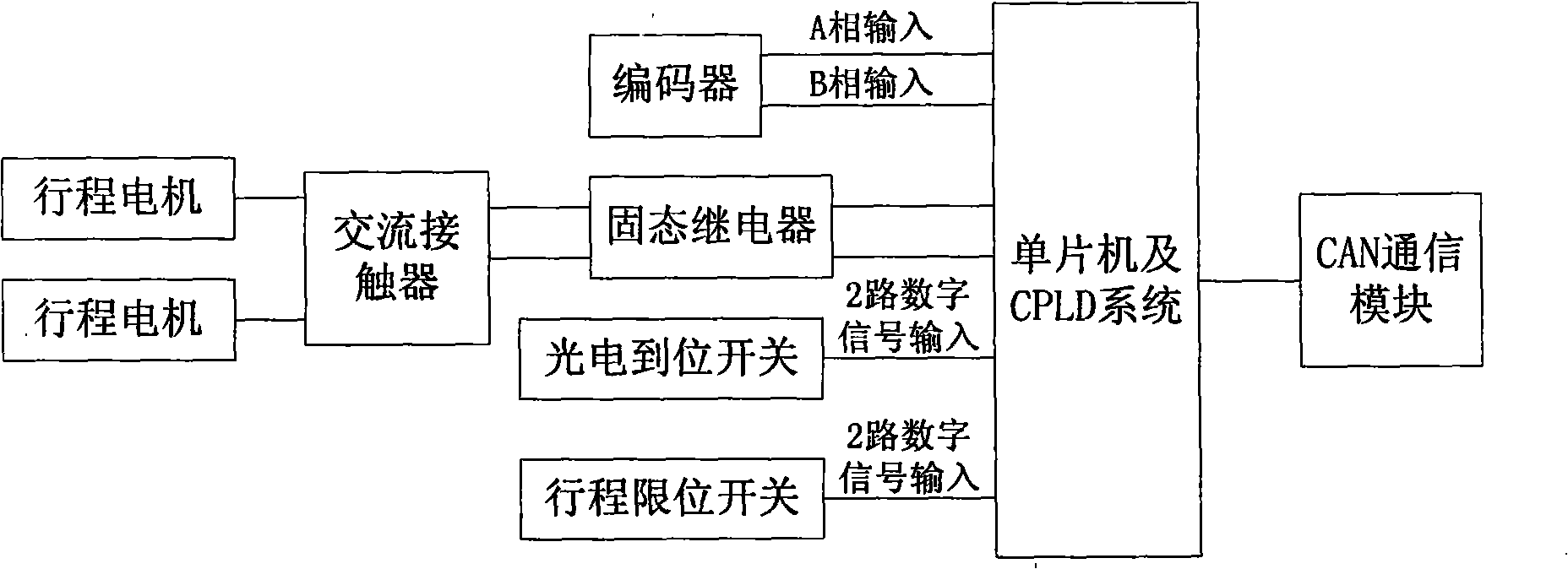

[0027] The automotive ABS test bench measurement and control system of the present invention consists of a motor, a pressure sensor, a speed encoder, a torque controller, an amplification filter circuit, an A / D conversion and data acquisition circuit, a single-chip microcomputer, a CAN bus, a computer, a printer, and a stand control system, etc. composition.

[0028] refer to figure 1 As shown, the driving motor 1 of the front frame is connected with the stroke control module, and is used for the front and rear movement of the front frame of the test bench. The motor is a positive and negative motor, and the direction of the motor is changed by changing the phase of the input current. 11, 12, 20, and 21 are lifting platforms, which are controlled by the lifting platform control module. The speed acquisition module collects the rotational speed of the drum during the ABS performance test through the drum speed encoders 34, 35, 36, 37, and calculates the corresponding wheel spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com