Impulse type cereal flux detection device

A technology for measuring grain flow and yield, which is applied in the direction of volume/mass flow generated by mechanical effects, and fluid flow detected by measuring pressure difference. It can solve the problems of measurement accuracy, poor dynamic response, and complex overall structure, and reduce equipment Cost, improvement of measurement accuracy, effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

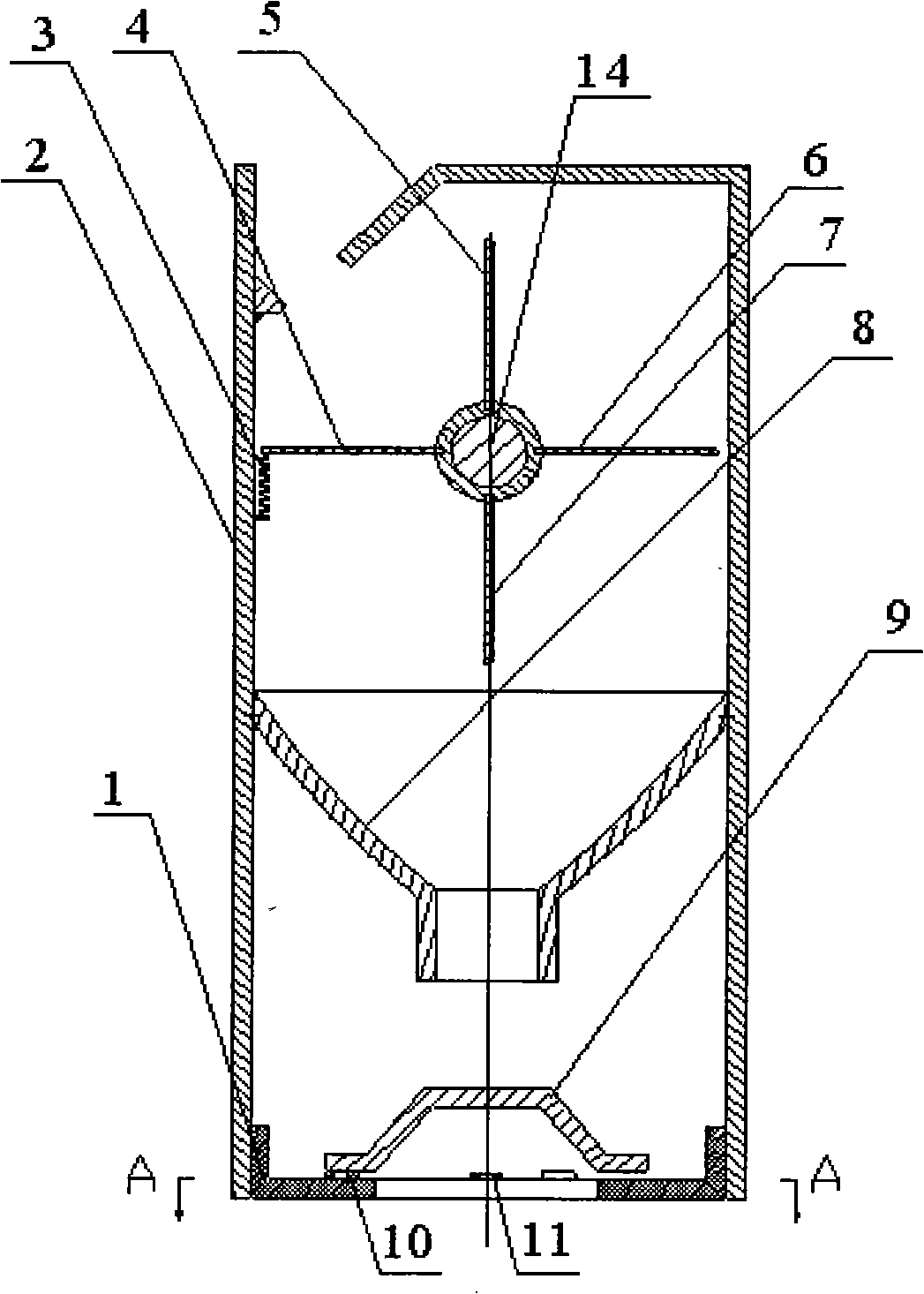

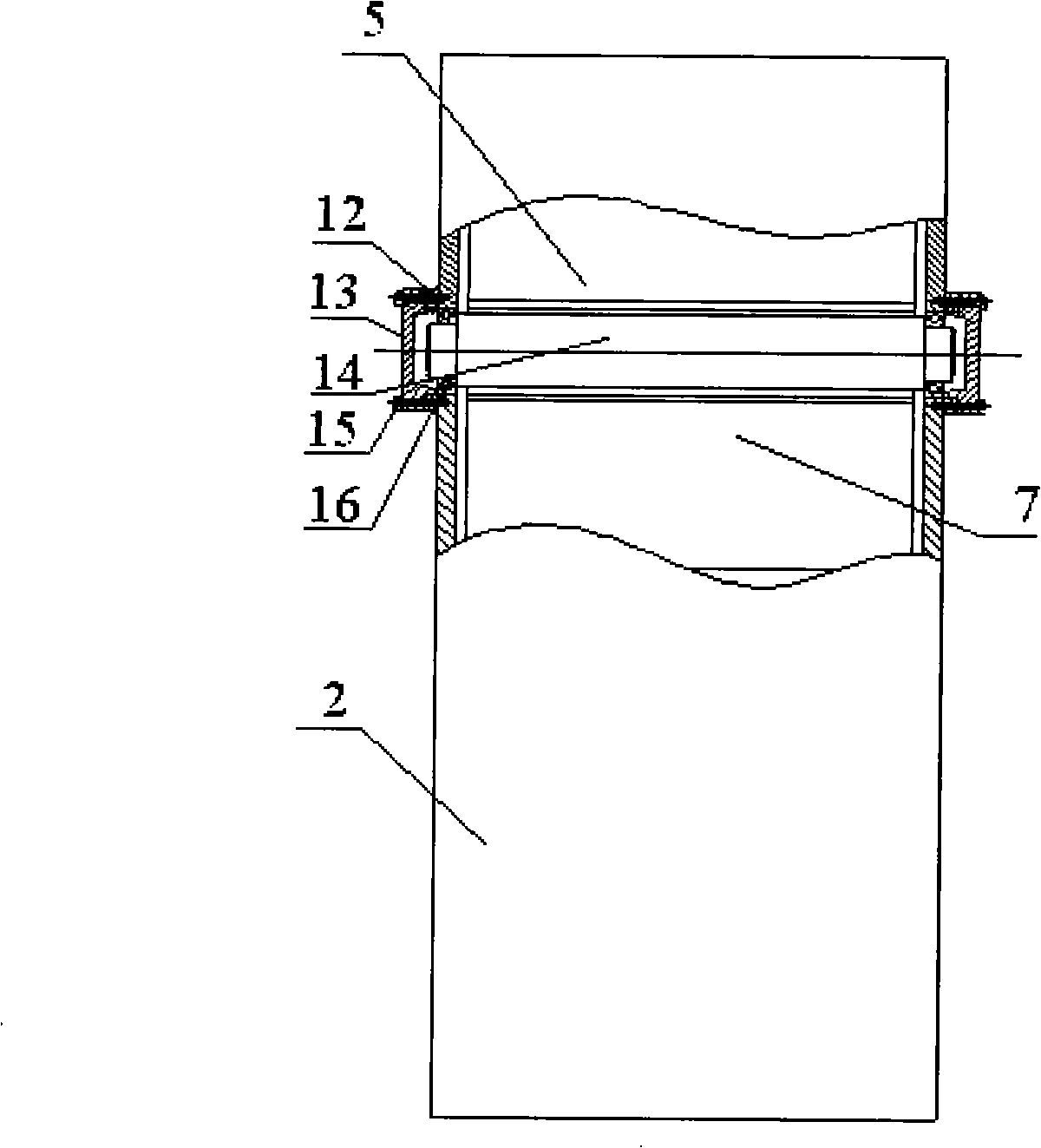

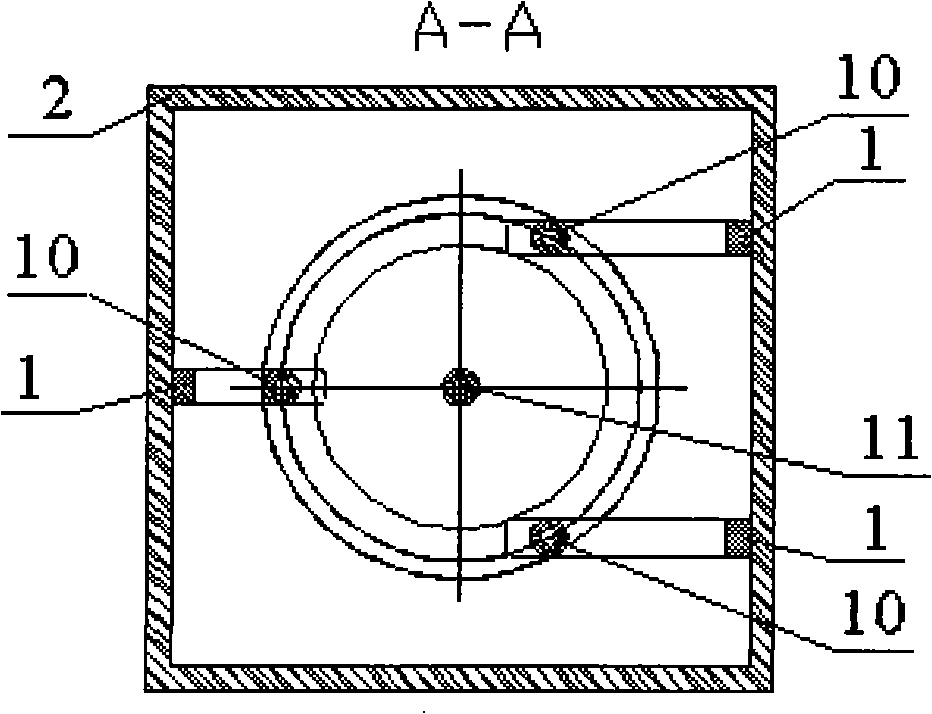

[0022] Such as figure 1 , 2 Shown, the whole device profile of the present invention is a square box shape, has a grain inlet on the top of the casing 2, and the cone-shaped grain diverter 8 is fixed on the casing 2 inner wall. The upper opening of the guide body 8 is fixed on the casing 2 inner wall, and the lower opening is a grain opening, which helps the grain to concentrate and fall. Fix the shaft 14 directly above the grain deflector 8, such as image 3 As shown, the two ends of the shaft 14 are firmly installed on the wall of the casing 2 through the bearing 16 and the corresponding bearing seat 12, the bearing cover 13 and the fixing screw 15. Four mutually perpendicular blades 4, 5, 6, 7 are fixed on the shaft 14. Wherein the blade 4 is arranged horizontally and its movable end is positioned at the below of the grain inlet. One end of the spring 3 is fixed on the inner wall of the box body 2, and the other end supports the movable end of the blade 4 in the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com