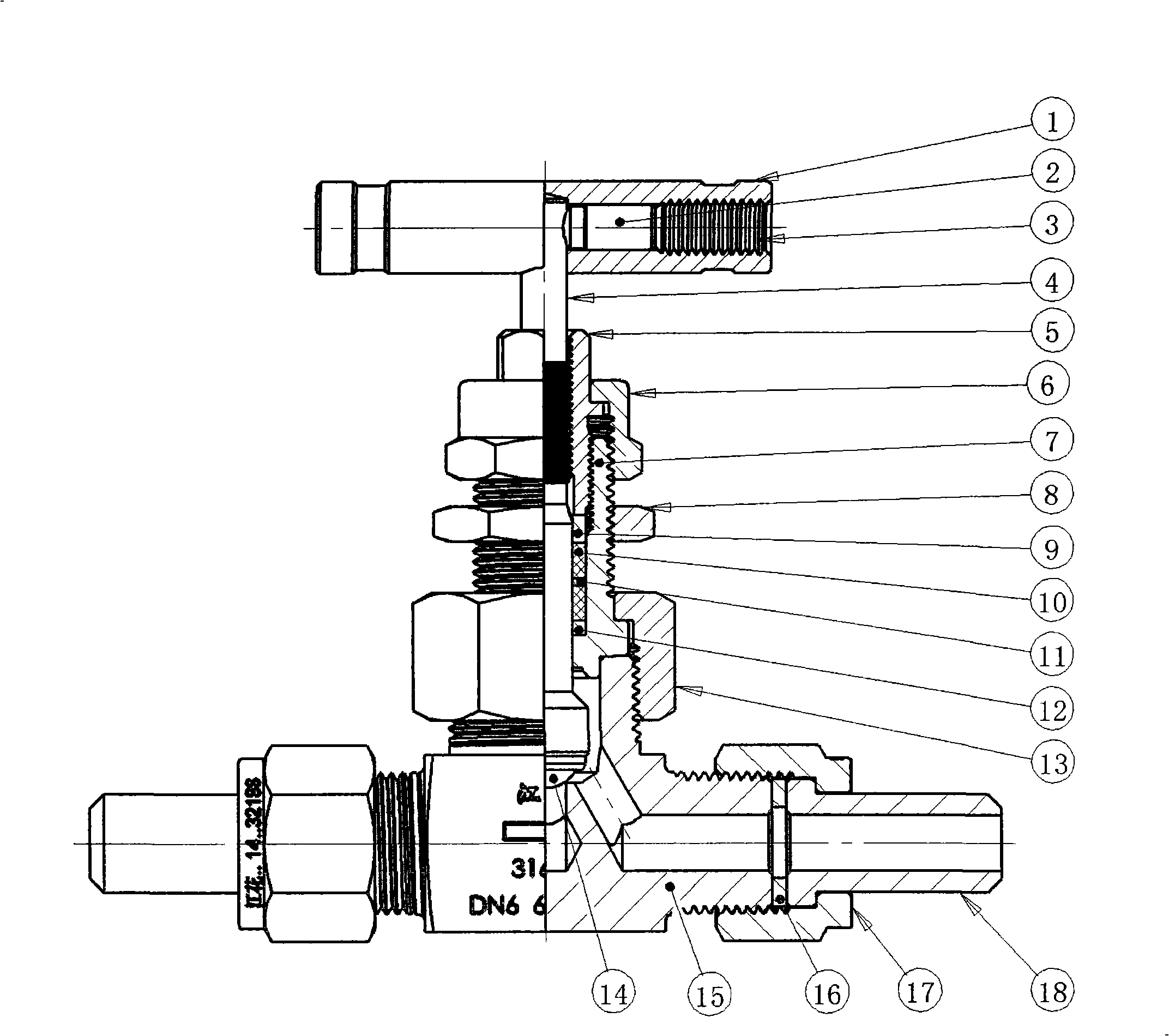

Combined valve cover type break valve

A globe valve and combined valve technology, applied in the field of globe valves, can solve the problems of hindering the flow of the medium in the pipeline, easy rust of the valve stem thread, low reliability, etc., to improve the sealing performance, prevent accidental loosening, social Good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] 1. The combined valve cover globe valve of the present invention adopts the structural design of the combined valve cover to ensure reliable sealing under harsh working environments, and provides the panel installation function;

[0012] 2. The valve stem 4 thread is designed above the sealing packing 10, which avoids the erosion of the valve stem thread and the scouring of the thread lubricant by the medium;

[0013] 3. The design of the packing bolt 5 enables the valve to perform packing adjustment in the closed or open position;

[0014] 4. The non-rotating spool 14 avoids scratches on the sealing surface and provides repeated non-leakage closures;

[0015] 5. Adjusting valve stem and stainless steel heat-treated conical valve disc can be provided;

[0016] 6. Through the improvement of the valve flow channel, it becomes a full-bore flow channel with large flow capacity;

[0017] 7. Various connection types, including double ferrule connection, union butt welding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com