Engine with novel oilway

An engine and oil channel technology, applied in the field of overhead valve engines, can solve the problems of high processing cost, inconsistent hole diameter at both ends, low oil pressure at the rear end of the oil channel, etc., achieve stable and reliable work, reduce processing difficulty, and balance oil pressure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

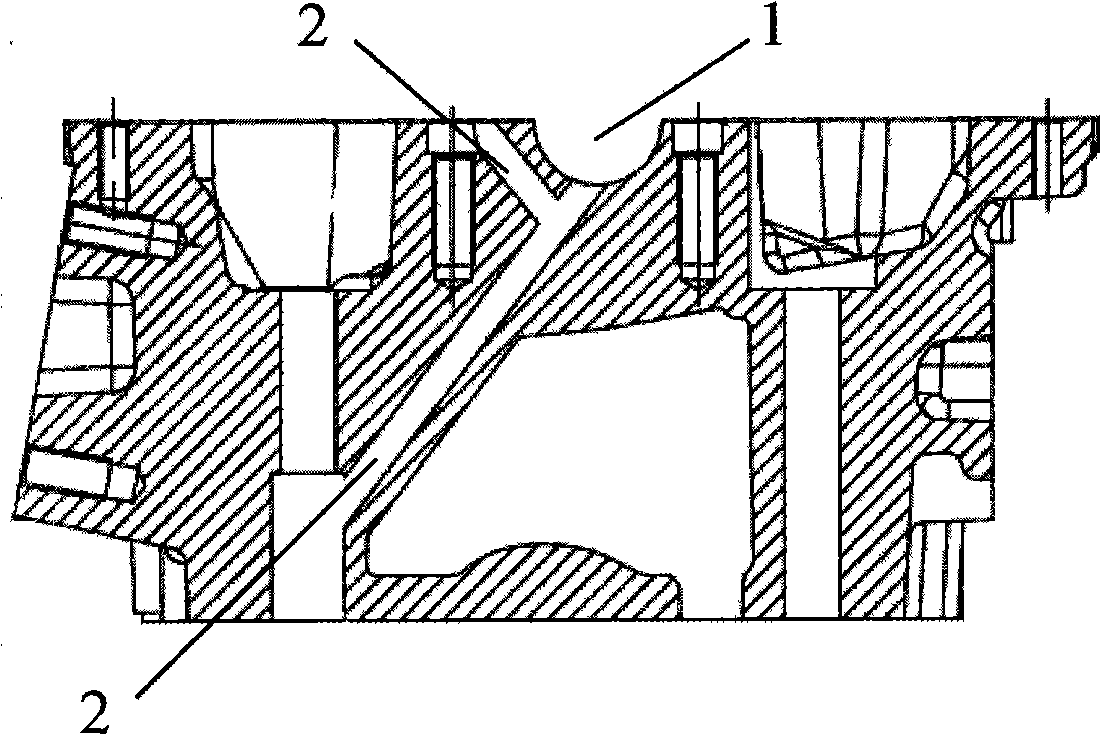

[0025] like figure 1 As shown, the cylinder head is provided with a main oil inlet passage 2 leading from the bottom of the cylinder head to the main journal hole of the camshaft and the middle position inside the camshaft bearing cap respectively. The oil passage in the main journal hole of the shaft and the oil passage that enters the inside of the camshaft bearing cap from the bottom of the cylinder head through the bolt hole in the middle of the cylinder head and the camshaft bearing cap. The main oil inlet passage 2 plays the role of supplying oil to the camshaft cover and lubricating the main journal hole of the camshaft.

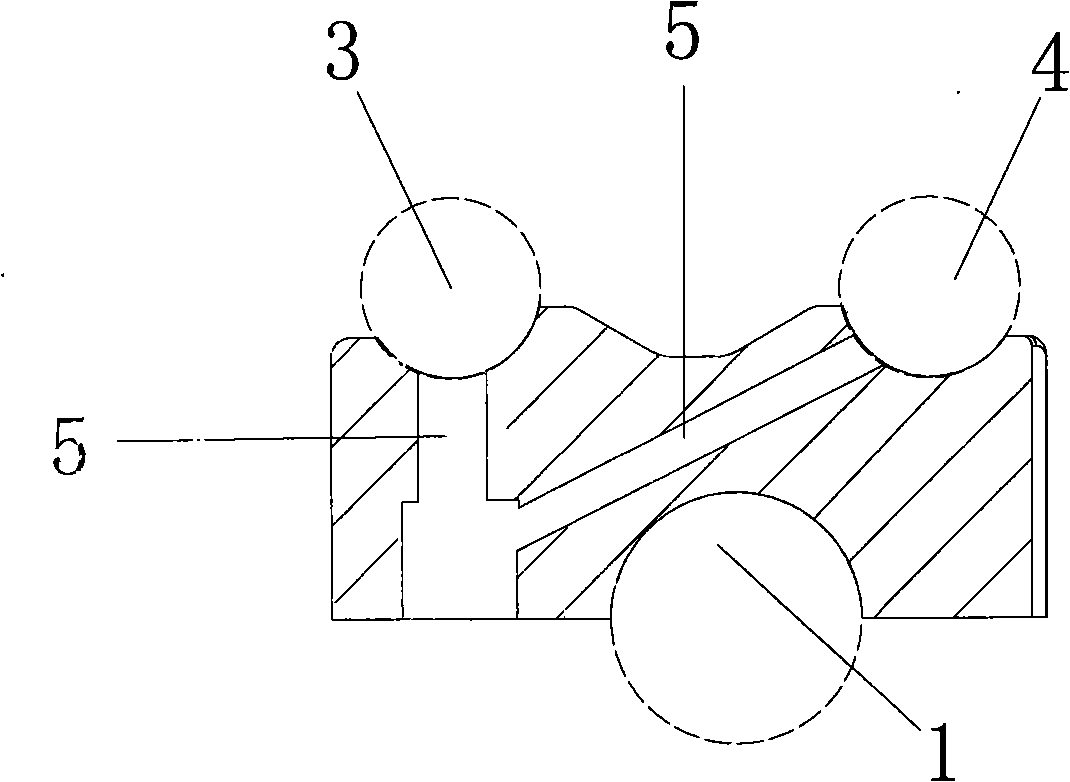

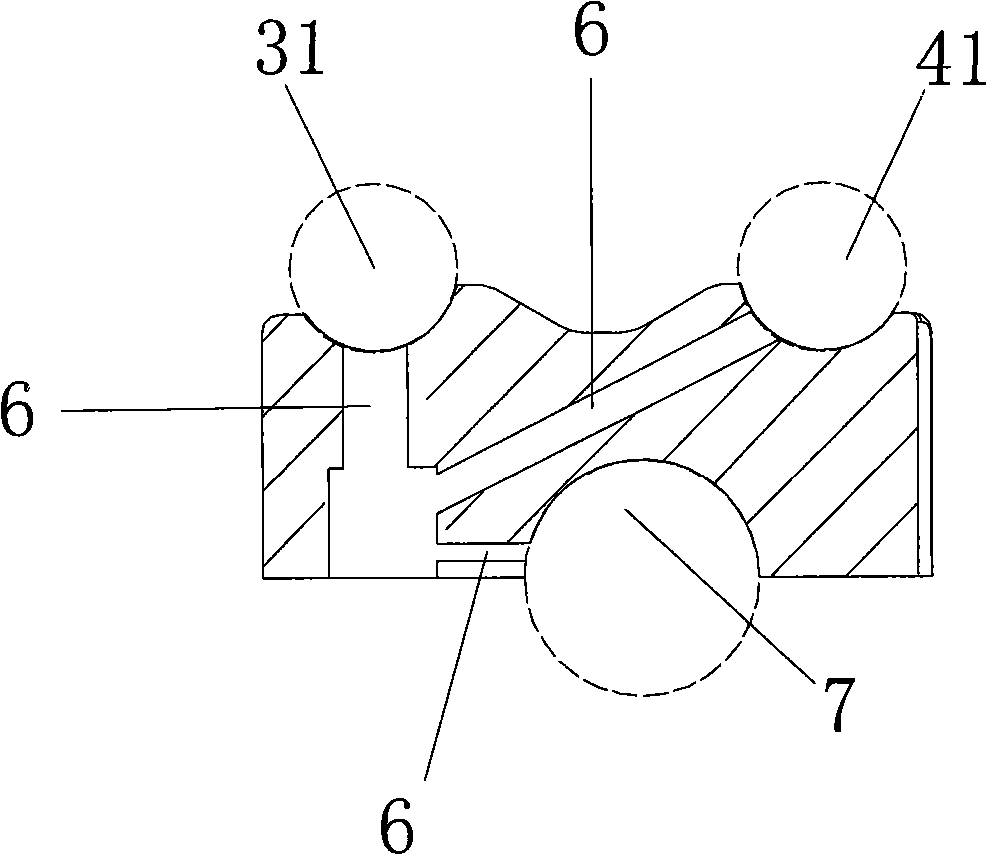

[0026] like figure 2 and image 3 As shown, the camshaft bearing cap is provided with a main oil passage 5 and a plurality of auxiliary oil passages 6, and the main oil passage 5 in the camshaft bearing cap leads to the air intake through the bolt hole in the middle position of the camshaft bearing cap. The oil passage in the central mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com