Salt (hot) thickening water-soluble polymer

A water-soluble polymer, polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as temperature rise, limited application, viscosity drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

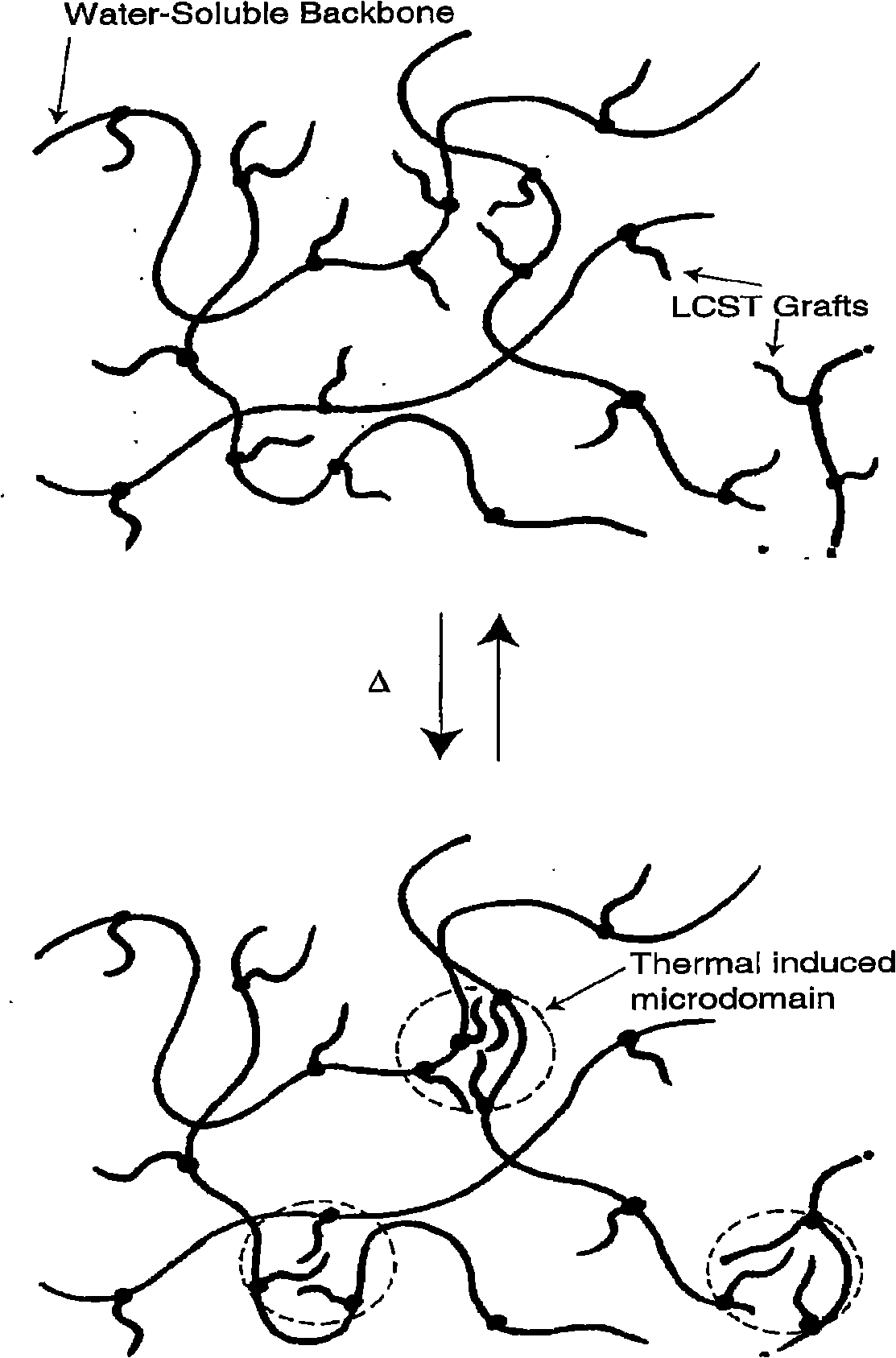

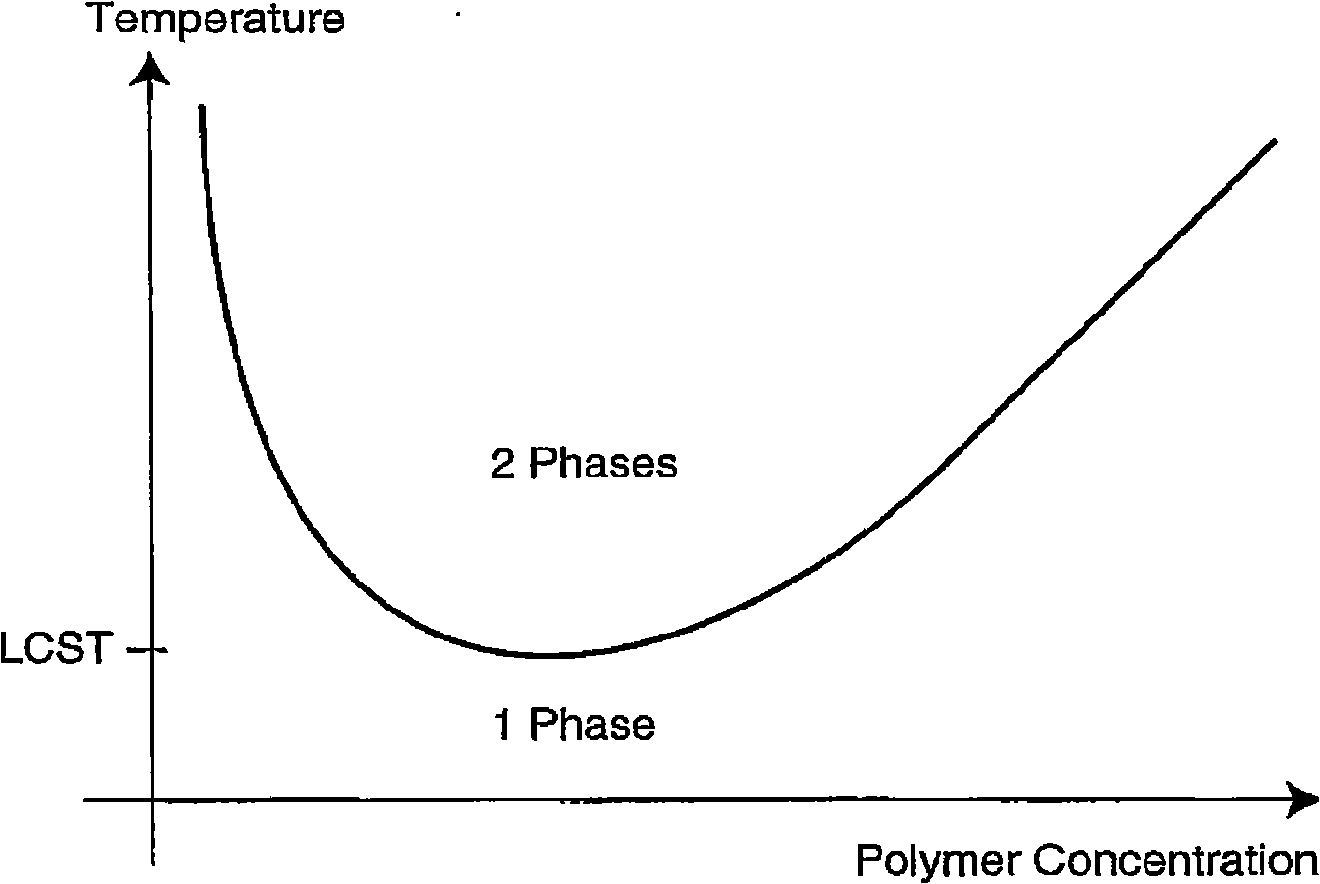

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

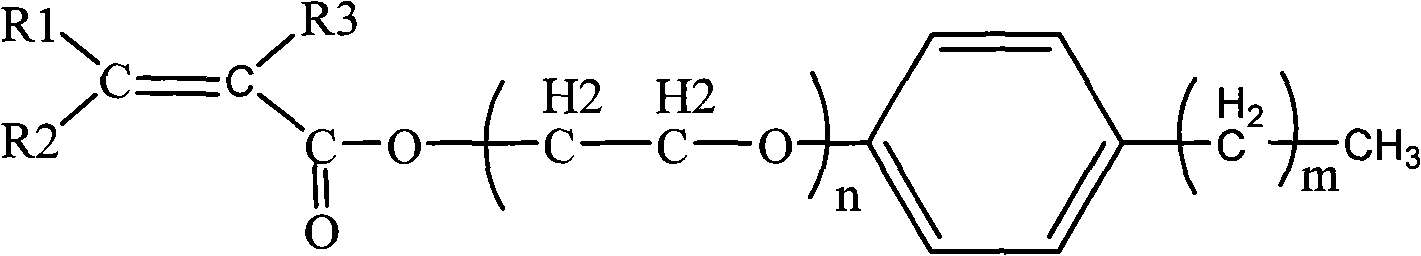

[0027] In the reaction vessel, add solvent dichloromethane 120ml, nonylphenol polyoxyethylene (OP-50) 0.01mol, cyclohexylcarbodiimide (DCCI) 0.012mol, 4-dimethylaminopyridine (DMAP) 0.04mol and 0.012mol of methacrylic acid (or acrylic acid), stirring continuously, controlling the stirring rate to 300rpm, reacting at room temperature for 12h, then filtering the mixture, and purifying the filtrate with ether five times to obtain a water-soluble macromonomer (B50).

Embodiment 2

[0029] In the reaction vessel, add solvent dichloromethane 120ml, nonylphenol polyoxyethylene (OP-70) 0.01mol, 1-cyclohexyl-3-(3,3-dimethylaminopropyl) carbodiimide iodine 0.016mol of methane quaternary ammonium salt, 0.06mol of 4-dimethylaminopyridine (DMAP) and 0.016mol of methacrylic acid (or acrylic acid), stirring constantly, controlling the stirring rate at 300rpm, reacting at room temperature for 25h, then filtering the mixture, and using the filtrate The ether was purified 5 times to obtain a water-soluble macromonomer (B70).

Embodiment 3

[0031] In the reaction vessel, add 80g of white oil and 40g of surfactant in a certain proportion, control the HLB value of the surfactant mixture between 9.2, control the temperature at 40°C, stir at 800rpm, and stir for 1.5h; according to the amount Acrylamide (monomer A) and monomer B (B50) were formulated into an aqueous solution (20 g) with a concentration of 55 wt% (the molar ratio of A to B was 99:1). Then, under the condition of stirring again, the aqueous monomer solution was slowly added dropwise, and the stirring was continued for 5 hours, and the temperature of the solution was controlled between 40°C. Continue to stir, control the stirring speed between 300rpm, pass high-purity nitrogen for 30 minutes, add water-soluble free radical initiator V500.15g, continue to pass nitrogen for 5 hours, and obtain transparent polymer microlatex with bluish light. Purify with absolute ethanol and 200# solvent naphtha as a precipitant to obtain small white particles. White powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com