Dual-speed self-tapping machine tool

An automatic tapping and machine tool technology, applied in the field of machine tools, can solve the problems of reducing work efficiency, unbalanced force on the power head, easy to attack deviation, etc., and achieve the effect of reducing labor intensity, improving work efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

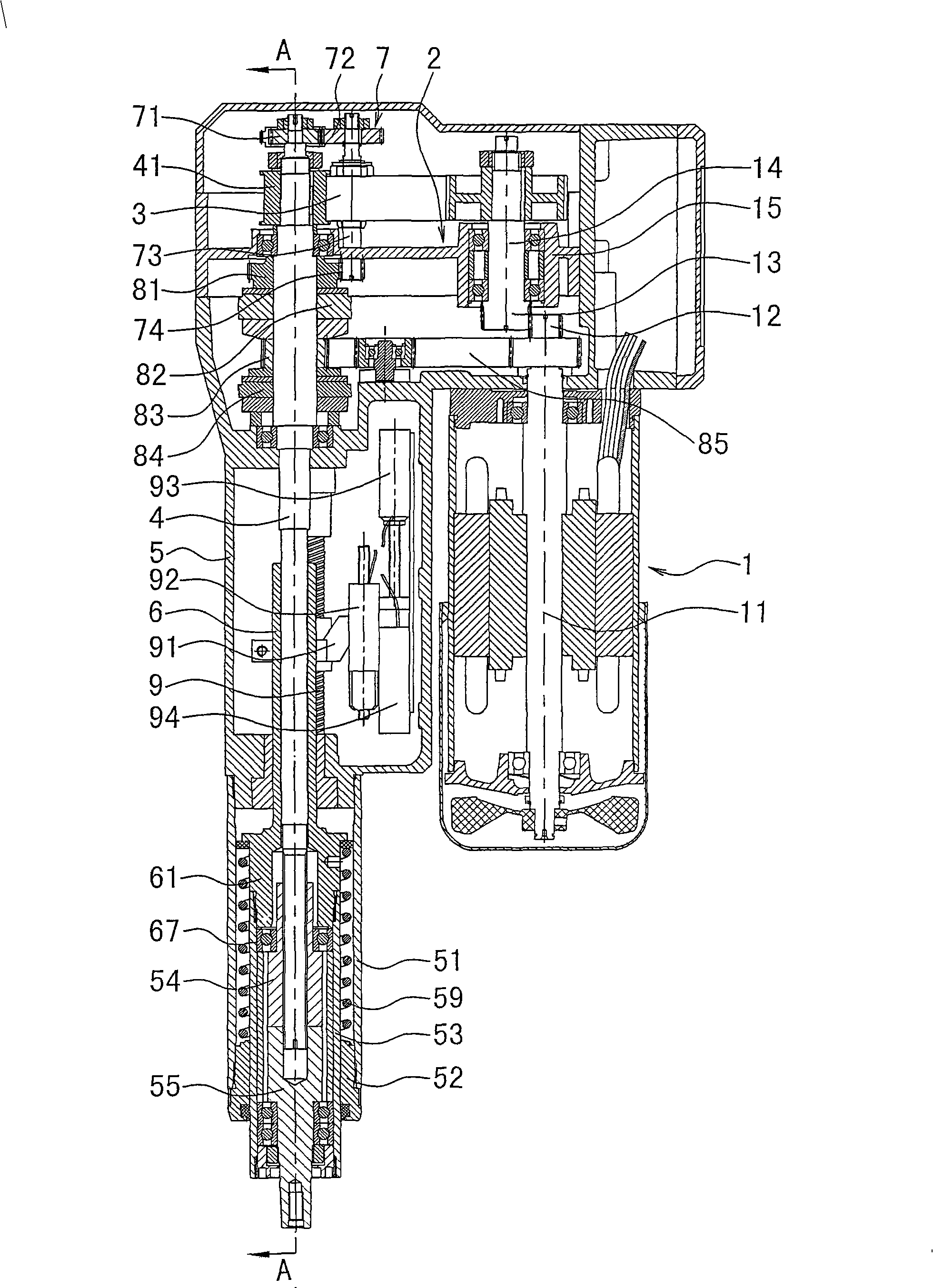

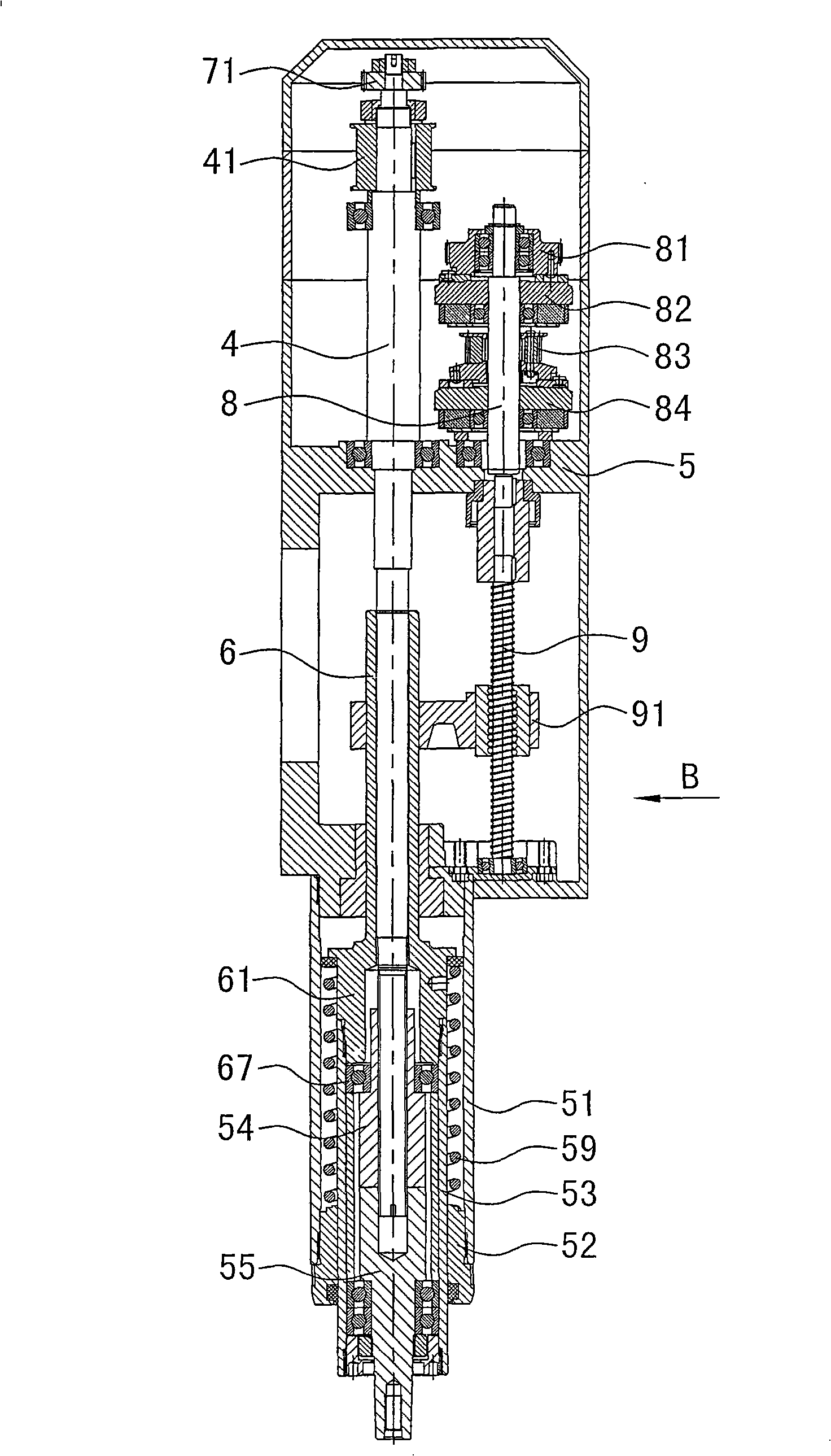

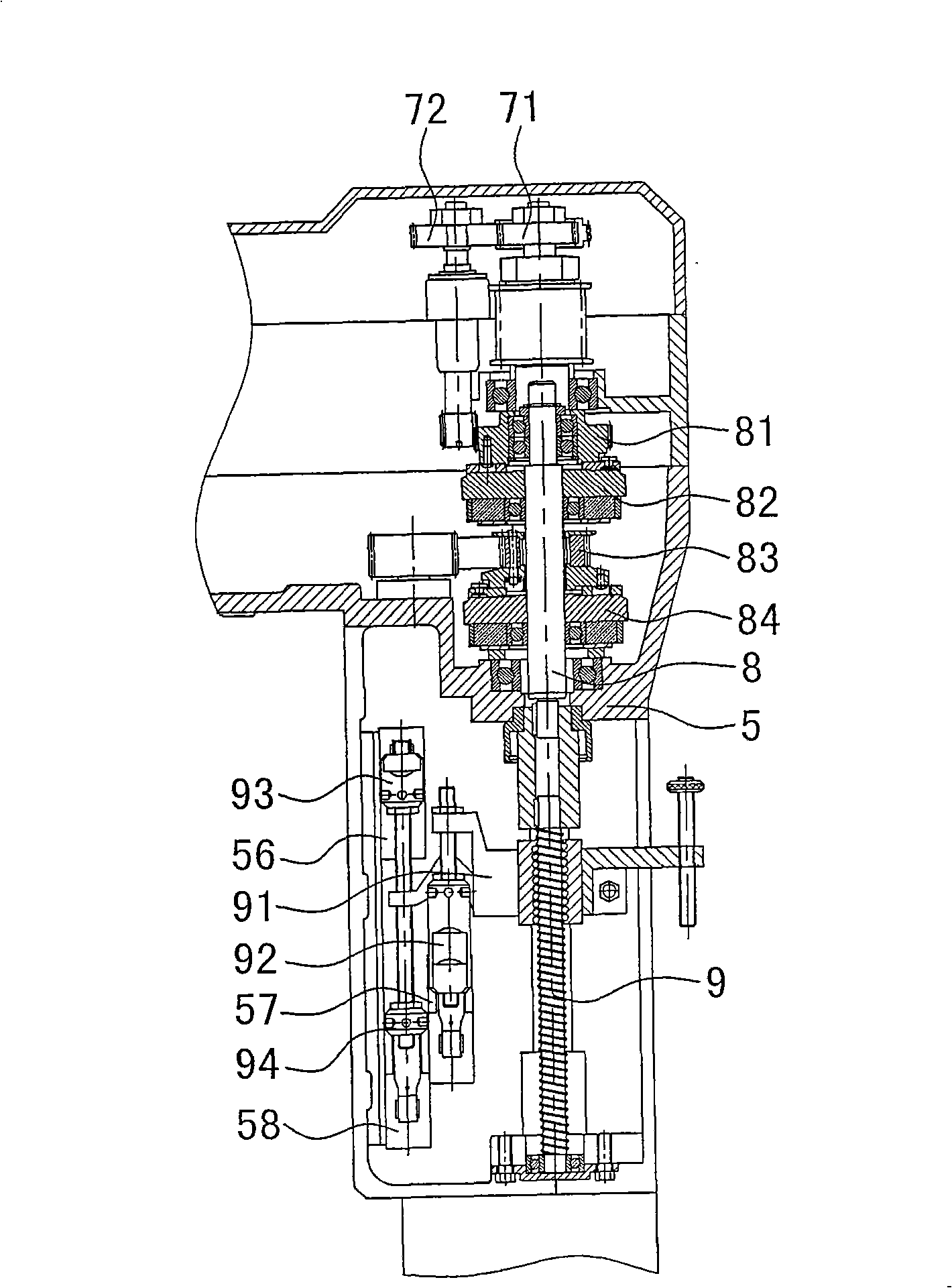

[0010] The invention discloses a two-speed automatic tapping machine tool, such as Figure 1-Figure 3 As shown, it includes the motor shaft 11 driven by the motor 1, the motor shaft is connected to the deceleration mechanism 2, the deceleration mechanism is meshed with the slow synchronous wheel 41 through the slow transmission belt 3, and the slow synchronous wheel 41 is fixed outside the spline shaft 4. The key shaft 4 is installed in the box body 5, and the middle and lower part of the spline shaft is movable to install the piston rod 6. The piston rod 6 is provided with a piston 61, and the bottom head of the spline shaft is screw connected with the power head. Connected outer cylinder 51, the outer cylinder is equipped with a lower end cover 52, a piston cylinder 53 is housed in the lower end cover, a spring 59 is housed between the piston cylinder 53 and the outer cylinder 51, and the top of the piston cylinder is in contact with the piston 61. Contact, the main shaft up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com