Marine plant for the automatic washing of boats, in particular for cleaning the hull

A technology for automatic cleaning and equipment, applied in the direction of ship cleaning devices, hulls, ship construction, etc., can solve the problems of non-negligible costs, performance degradation, and increased consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

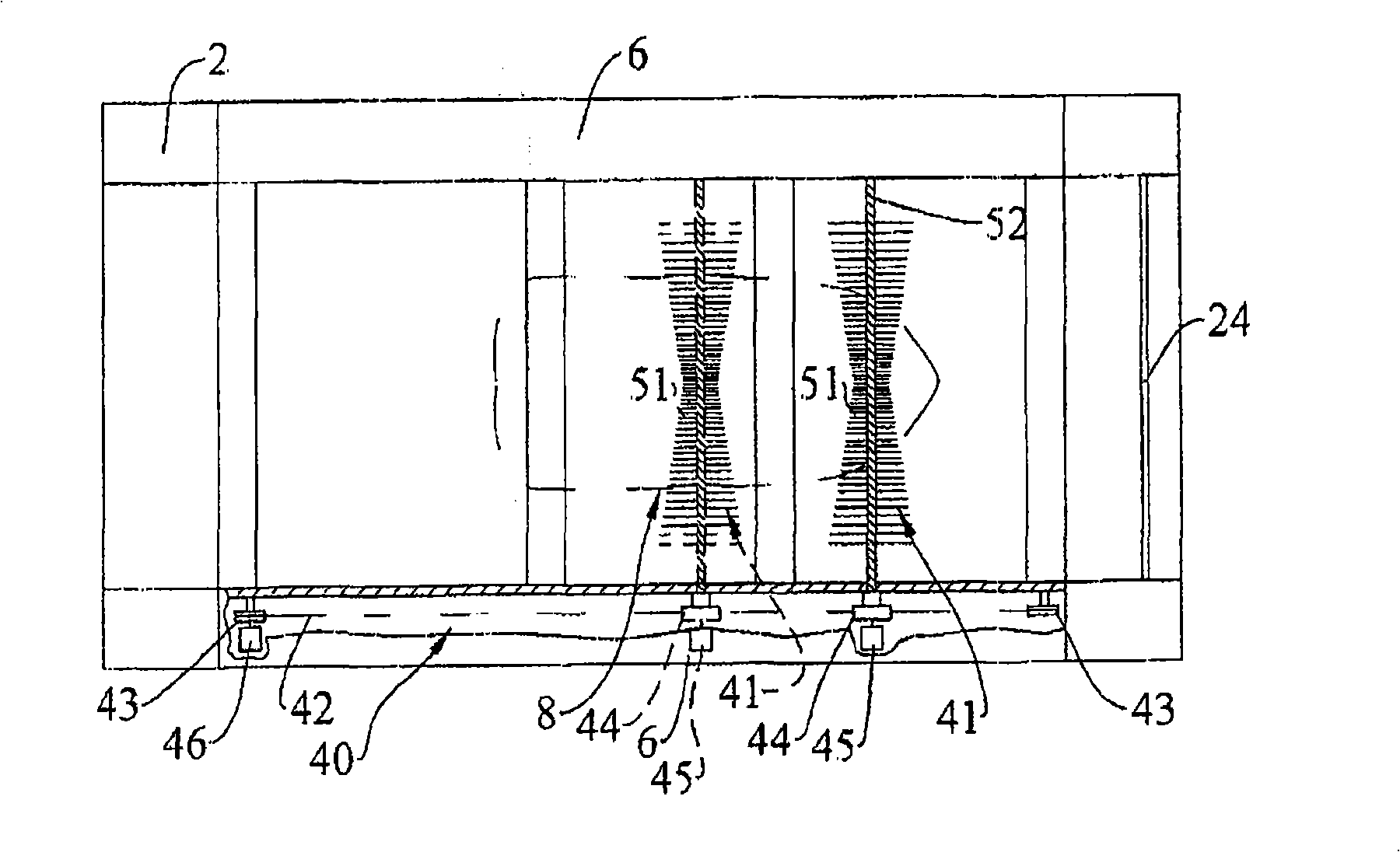

[0033] The offshore installation shown in Figures 1-6 comprises a support structure 1 made of steel or other rigid material, resting (or anchored) on the seabed and partially submerged, the support structure having hollow columns 2, fixed stringers 3 and the fixed beam 4.

[0034] The pillar 2 supports a pair of hollow beams 5-6 (upper beam 5 and lower beam 6) movable in the vertical direction and a device 7 for locking a vessel 8 floating on water 9 to a position by the sea. within the pool formed by the device itself.

[0035] Said locking device 7 , controlled by the operator using a control unit 200 ( FIG. 1 ), comprises a telescopic movable rod 10 articulated to the strut 2 , ending in a plate 11 resting on the hull 12 of the vessel 8 . The plate is covered with a soft material so that when it comes into contact with the hull 12 it will not damage the hull.

[0036] A chain transmission mechanism 13 for vertical movement of the upper beam 5 and a chain transmission mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com