A kind of manufacturing method of double-layer ultra-thin warm-keeping cloth and warm-keeping cloth

A manufacturing method and fabric technology, applied in textiles and papermaking, fabrics, multi-strand fabrics, etc., can solve the problems of difficult to meet the aesthetic pursuit of modern people, the thermal insulation effect is not ideal, and the thermal resistance of the yarn is low. The effect of strength, thickness increase, raw material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

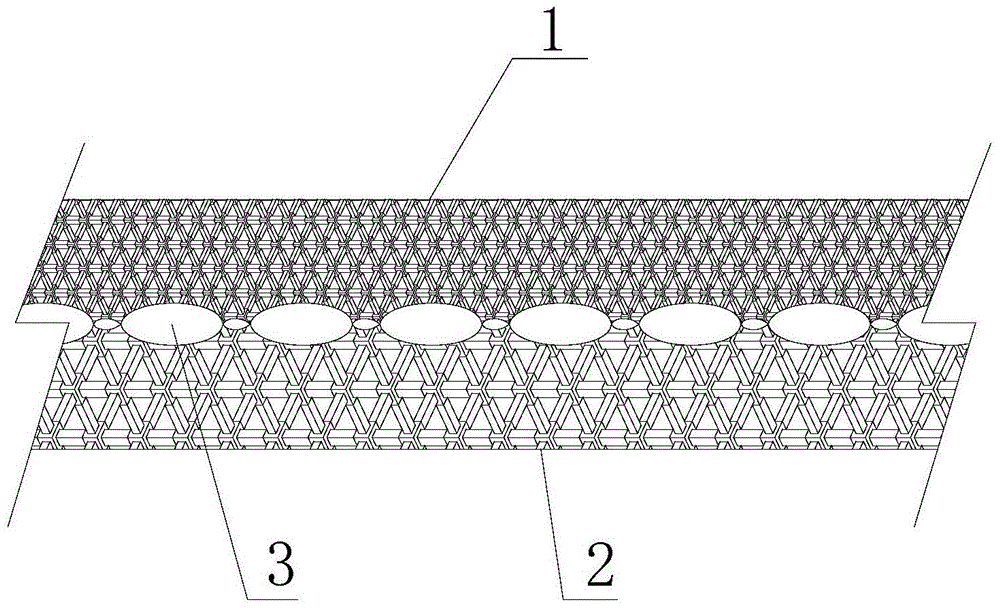

[0028] The invention relates to a manufacturing method of a double-layer ultra-thin warm-keeping cloth, which adopts a double-layer weaving method to form a surface cloth and a bottom cloth at the same time, and uses connecting warp yarns to connect the surface cloth and the bottom cloth together. Specific steps include:

[0029] First divide the warp yarns into surface warp yarns and bottom surface warp yarns alternately according to the ratio of 1:1, and set a connecting warp yarn every 8 warp yarns. Then the weft yarns are alternately divided into surface weft yarns and bottom weft yarns in a ratio of 1:1.

[0030] Then the surface warp yarn and the surface weft yarn are woven together to form a surface layer cloth, the bottom surface warp yarn and the bottom surface weft yarn are woven together to form a bottom layer cloth, and the surface layer cloth and the bottom layer cloth are connected with the connecting warp yarn. Here, two adjacent connecting warp yarns are not c...

Embodiment 2

[0033] The invention relates to a manufacturing method of a double-layer ultra-thin warm-keeping cloth, which adopts a double-layer weaving method to form a surface cloth and a bottom cloth at the same time, and uses connecting warp yarns to connect the surface cloth and the bottom cloth together. The specific steps include: first dividing the warp yarns into surface warp yarns and bottom surface warp yarns alternately according to the ratio of 1:1, and setting a connecting warp yarn every 6 warp yarns. Then the weft yarns are alternately divided into surface weft yarns and bottom weft yarns in a ratio of 2:1. By properly reducing the intervals between the warp yarns, the strength of the fabric is improved, and the fabric is prevented from being hardened due to too close intervals, which affects the feel and comfort.

[0034] The principle of the manufacturing method of a double-layer ultra-thin thermal fabric provided by this embodiment is basically the same as that of Embodi...

Embodiment 3

[0036] The invention relates to a manufacturing method of a double-layer ultra-thin warm-keeping cloth, which adopts a double-layer weaving method to form a surface cloth and a bottom cloth at the same time, and uses connecting warp yarns to connect the surface cloth and the bottom cloth together. The specific steps include: first dividing the warp yarns into surface warp yarns and bottom surface warp yarns alternately according to the ratio of 2:1, and setting a connecting warp yarn every 5 warp yarns. Then the weft yarns are alternately divided into surface weft yarns and bottom weft yarns in a ratio of 2:1.

[0037] The total number of warp yarns is 14000, the average diameter of the surface warp yarns and surface weft yarns is 0.15 mm, and the average diameter of the bottom surface warp yarns and bottom surface weft yarns is 0.40 mm. The sum of the densities of the surface weft yarns and the bottom weft yarns is 35 threads / cm. By increasing the number of surface warp yarn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com