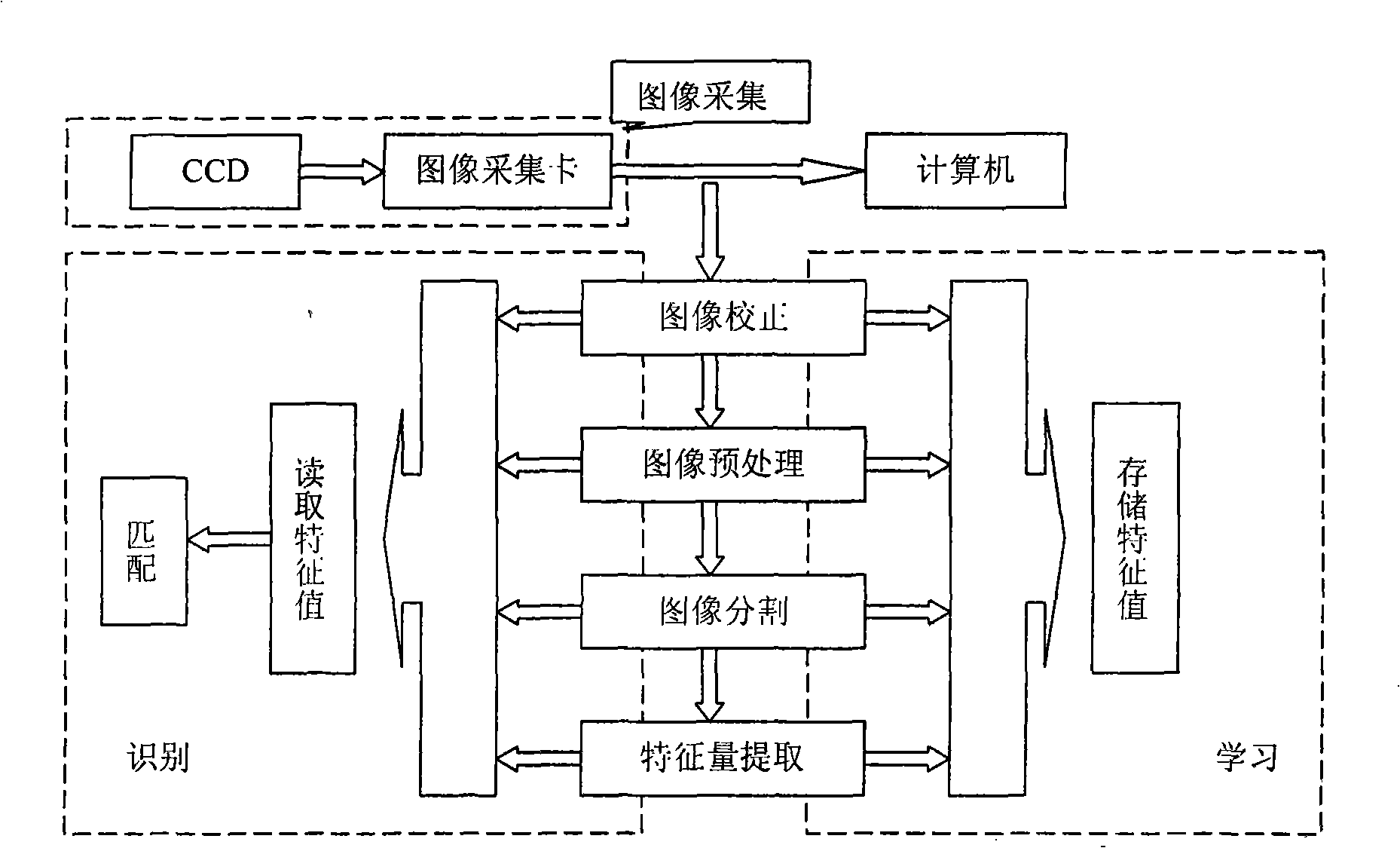

Image processing process of full-automatic lead wire bonding machine image processing system

A wire bonding machine and image processing technology, applied in image data processing, image enhancement, image analysis, etc., can solve problems affecting image quality, difficulty in image processing, inconsistency between imaging system and ideal pinhole model, etc., to achieve automatic Alignment, the effect of improving alignment and positioning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

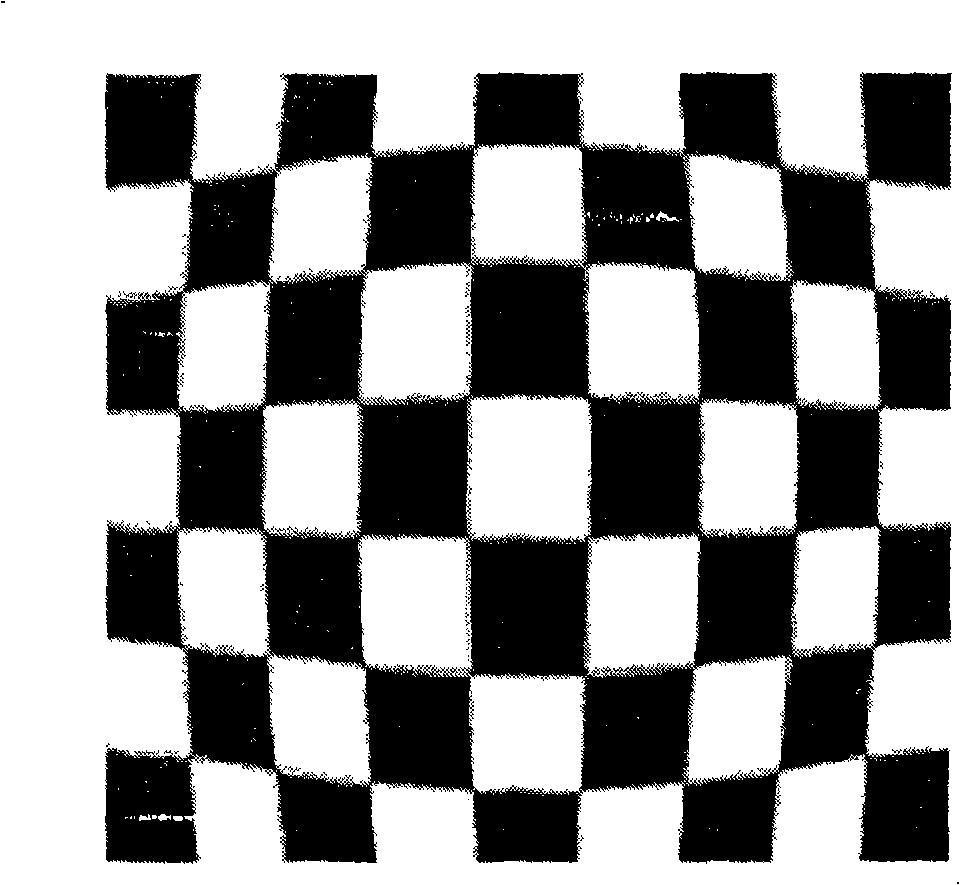

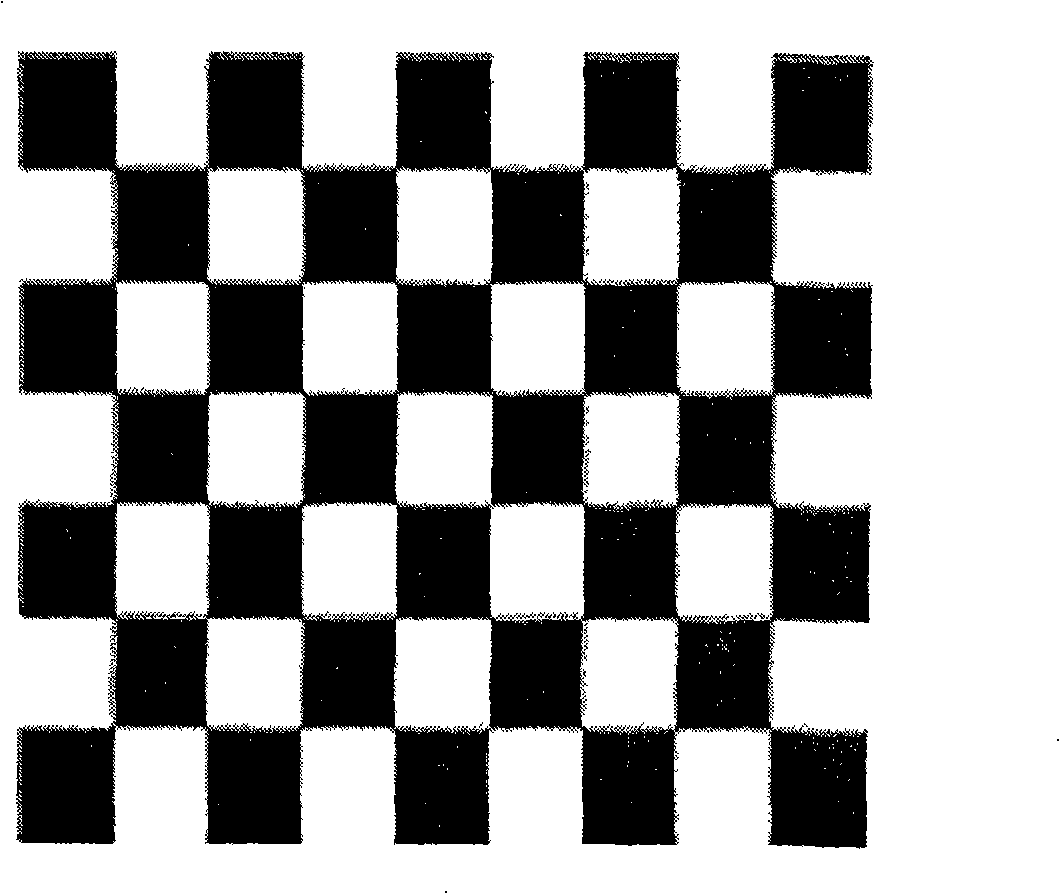

Method used

Image

Examples

Embodiment Construction

[0023] Just operate according to the technical solution in the summary of the invention above.

[0024] Once the pin feature points and chip feature points are identified, the system will automatically calculate the chip loading error and pin error, and correct the distance between the inner solder joint and the outer solder joint. According to the position difference, the workbench is adjusted by the control card of the motion control system of the wire bonding machine, and the distance between the inner soldering point and the outer soldering point on the integrated circuit is determined. In addition, the distance between the inner solder joints on the chip and the outer solder joints on the pins is not affected by chip mounting errors and pin errors. Therefore, all kinds of data required to realize fully automatic wire bonding have been determined. At this point, the position of the chip is precisely positioned, and the wire bonding machine can complete the precise bonding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com