Method for correct measurement for wave-guide wide edge gap admittance of millimeter wave frequency range

A technology for measuring waves and broadsides, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of phase error, affecting the accuracy of measurement results, etc., to reduce phase error, easy to operate, The effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

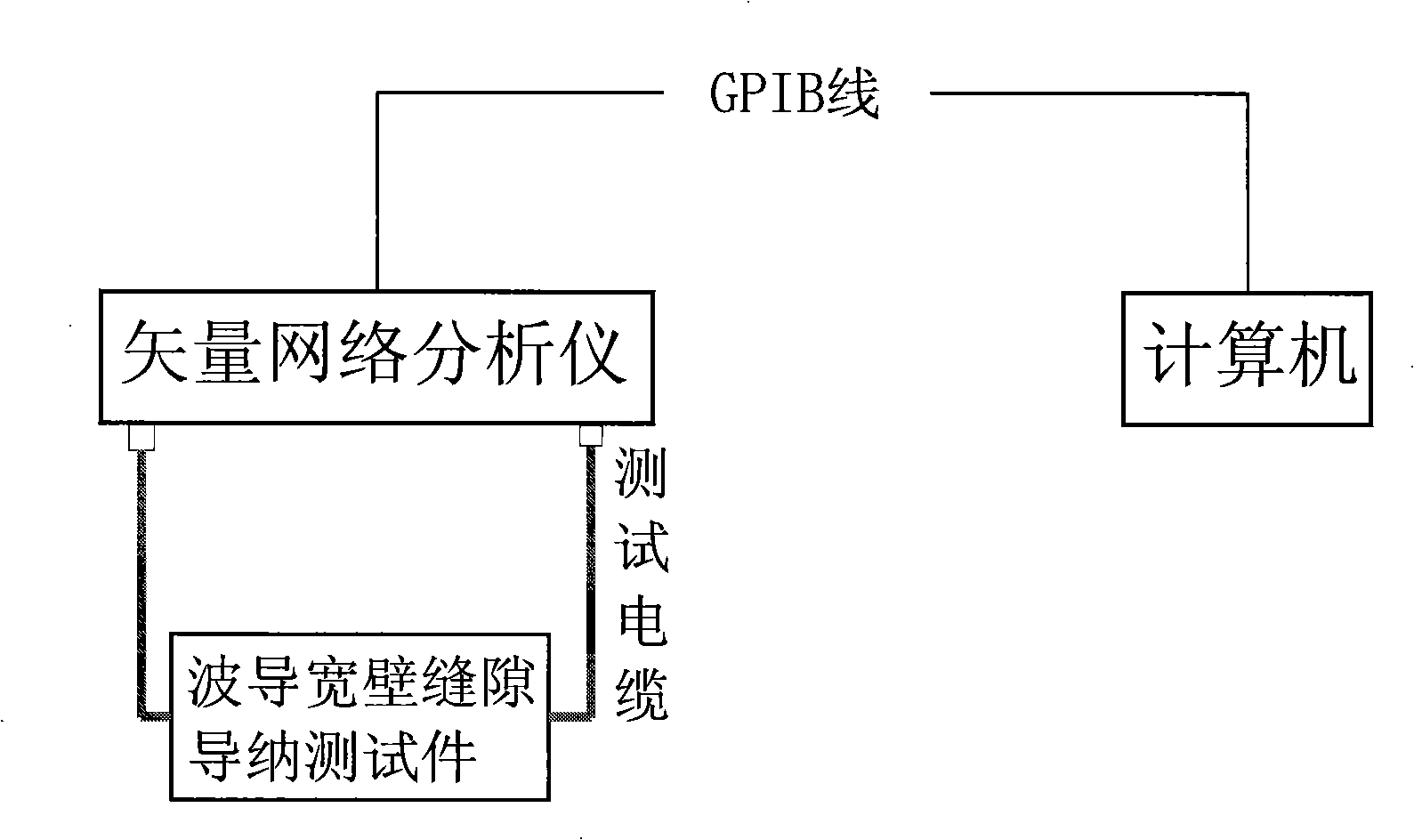

[0013] see figure 1 , figure 2 . According to the present invention, use vector network analyzer to electrically connect the computer that contains mathematical analysis software program, set up test platform; coaxial-to-waveguide converter. One end of transmission line L1 is used as standard 1, the other section of transmission line L2 is used as standard 2, and the reflector is used as standard 3 to form two transmission standards and one reflection standard (transmission line L1-reflector R-transmission line L2) LRL calibration form.

[0014] When calibrating the vector network analyzer, connect the two test cables of the vector network analyzer to both ends of a waveguide used as a transmission standard. The length of the waveguide is the same as the length of the tested admittance test piece, and the S-parameters of the tested transmission waveguide are measured. Connect a test cable of the vector network analyzer to a short-circuited waveguide used as a reflection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com