Wrapping executing structure of high-density over lock machine of cup seaming machine

A high-density technology with execution structure, applied in sewing machine ferrules, sewing machine components, sewing machine needle holders, etc., can solve the problems of affecting aesthetics, extremely thin materials cannot meet the requirements of hemming, and reduce the amount of thread used. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

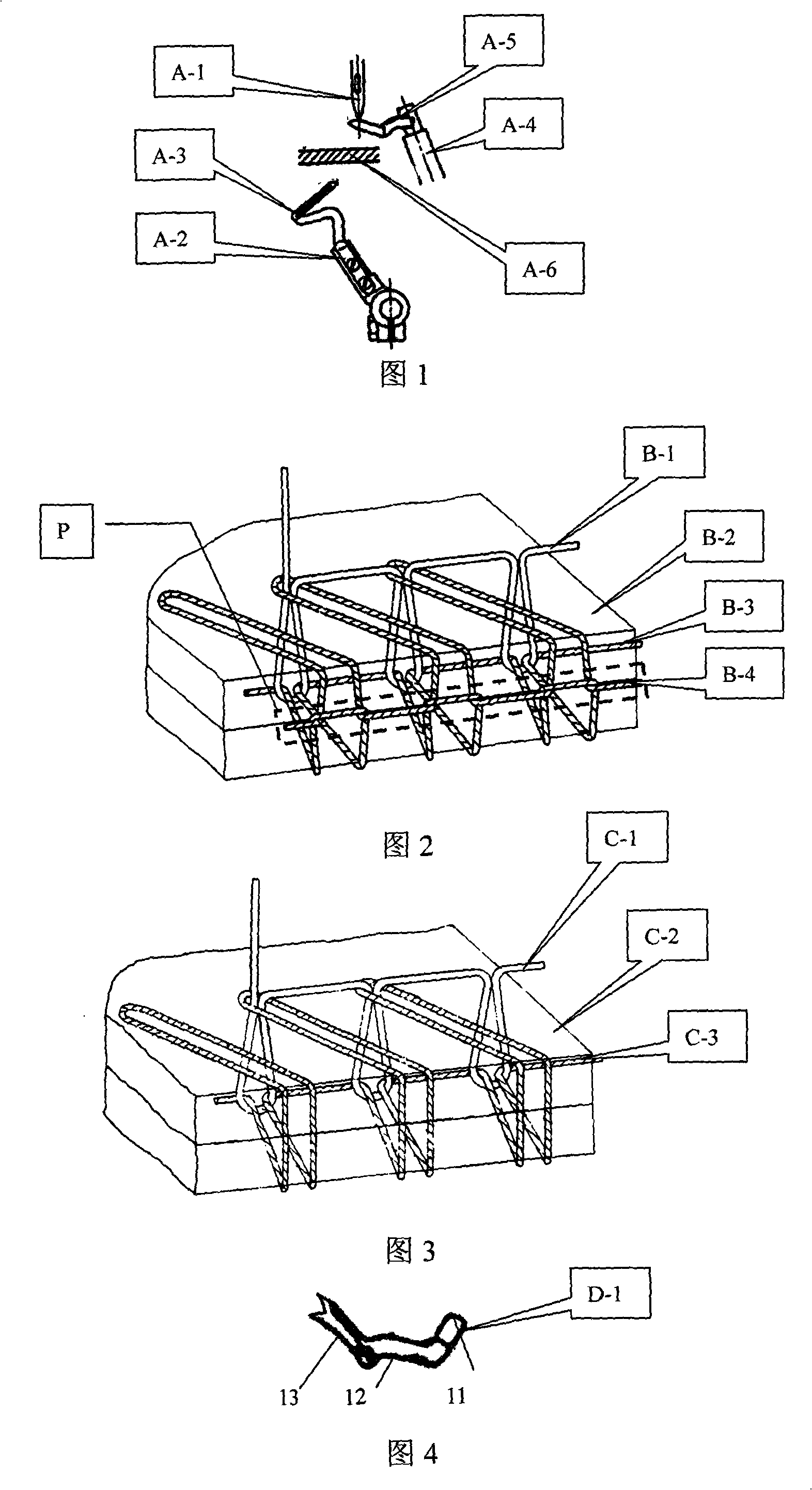

[0015] It can be seen from Figures 1 and 4 that the present invention includes: a needle A-1, a lower looper A-3 mounted on the lower looper rocker A-2, an upper looper guide rod A-4, and a needle plate A -6; It also includes a fork needle D-1 that only plays the role of pulling the thread and no longer uses suture; the fork needle D-1 is installed on the upper looper guide rod A-4;

[0016] The shape of the fork needle D-1 is: a cylindrical mounting handle 11 (approximately 7mm long), a cylindrical connecting body 12 (approximately 10mm long), 95-100° between the two Included angle, there is also a fork 13 at the front end of the working part.

[0017] It can be seen from Fig. 3 that the loop of needle thread C-1 is used to penetrate into the loop of the lower looper thread C-3 of the overlock material and into the sewing material C-2, which is expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com