A kind of sewing machine to go to the bird's nest and quickly change the knife with a knife presser foot

A sewing machine and presser foot technology, applied in the field of sewing machines, can solve the problems of missing stitches, increase defective products, troublesome replacement, etc., and achieve the effects of ensuring sewing performance, short residual thread ends, and beautiful stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

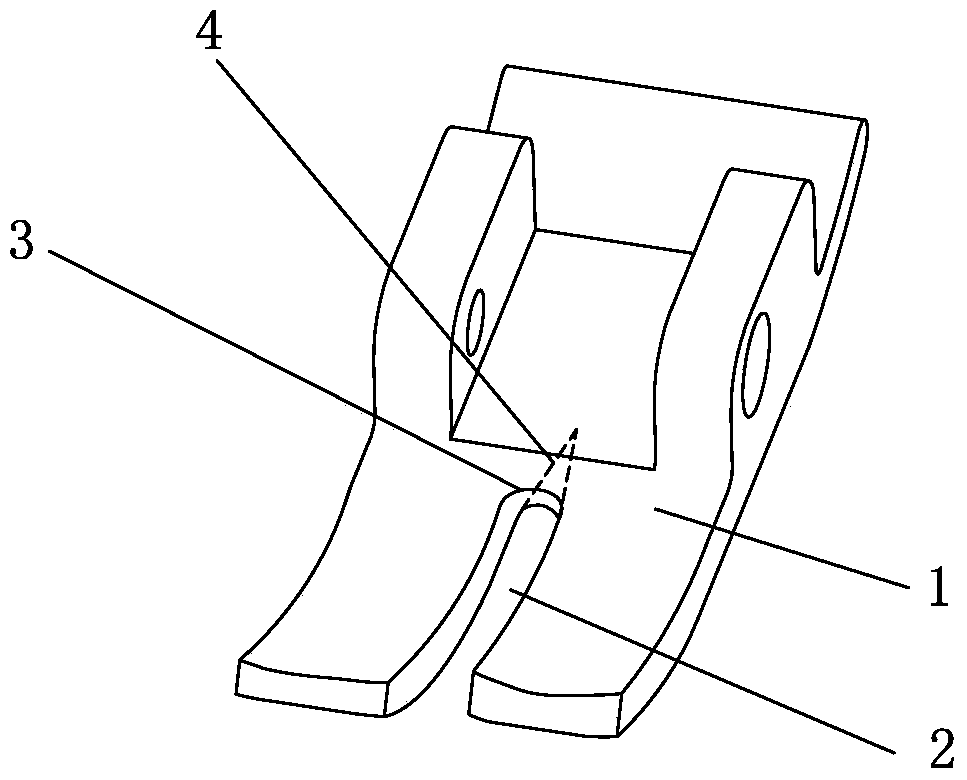

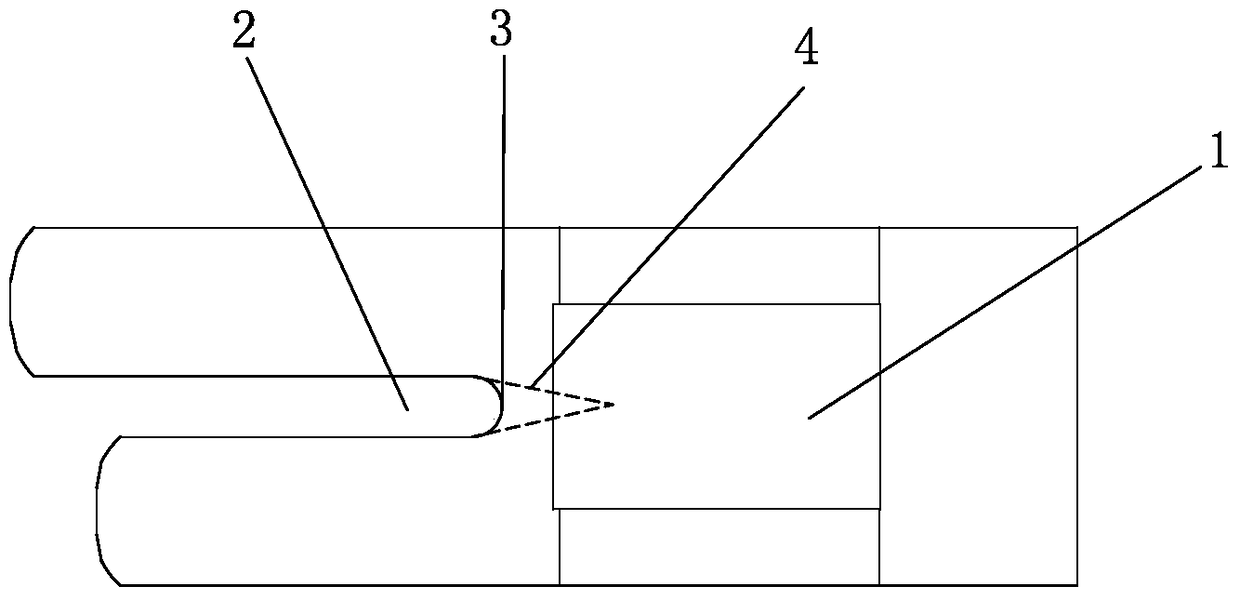

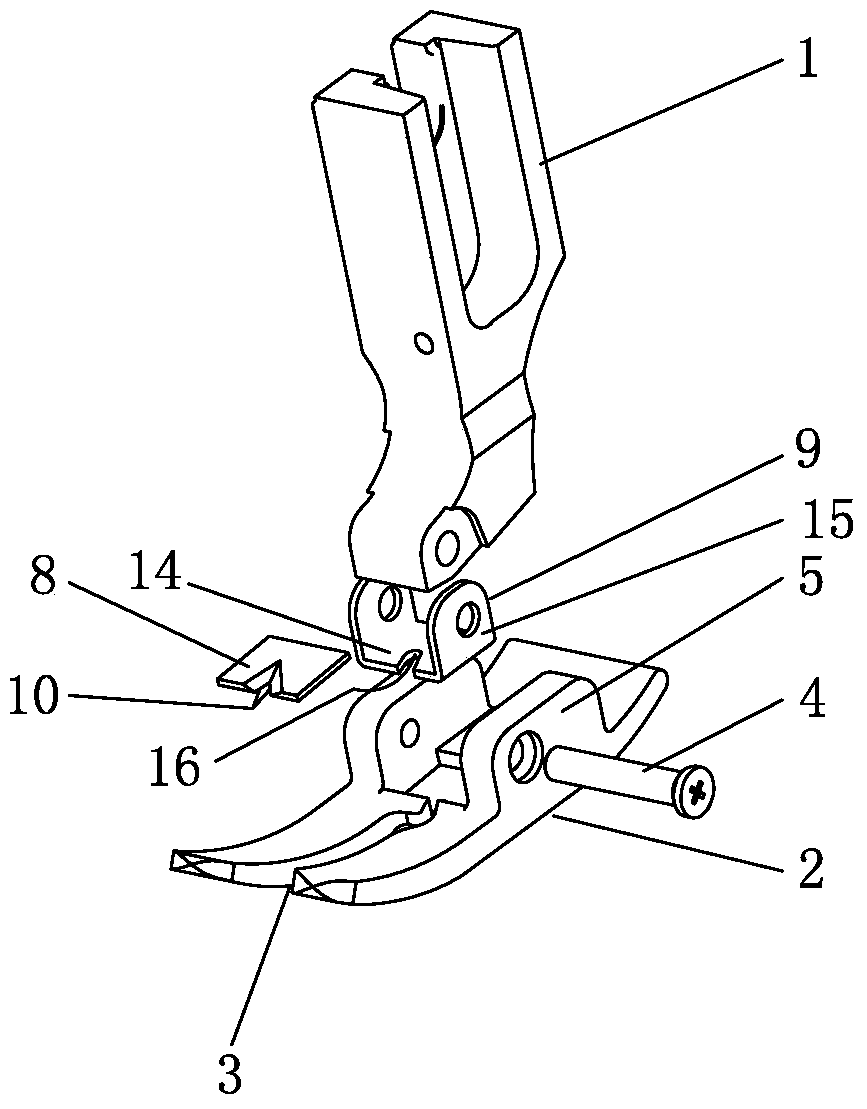

[0035] A sewing machine presser foot with a knife for quick tool change without bird's nest, including a presser handle 1 and a presser plate 2, a central thread groove 3 is arranged at the front of the presser plate 2, and the presser handle 1 is connected to the presser plate 2 through a screw 4 or a pin The two connecting parts 5 are hinged with the presser foot plate 2, and the presser foot plate 2 at the rear end of the central wire groove 3 is provided with a wire groove 6, the central wire groove 3 communicates with the wire groove 6, and the presser foot plate between the two connecting parts 5 A blade groove 7 is formed on the 2, the end of the wire passing groove 6 is located in the blade groove 7, and the blade 8 is arranged in the blade groove 7, and the blade 8 of the blade 8 is positioned above the wire passing groove 6. When installing blade 8 and changing blade 8, unscrew screw 4 or pin, pull down presser foot handle 1 and can realize quick tool change.

[0036...

Embodiment 2

[0043] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that a blade pressing plate 9 is provided between the blade 8 and the presser handle 1 . The specific structure is as follows:

[0044] A blade pressing plate 9 is arranged between the upper plane of the blade 8 and the bottom plane of the presser handle 1 , and the blade pressing plate 9 presses the blade 8 into the blade groove 7 .

[0045] The structure of the blade pressing plate 9 is that the two ends of the horizontal plate 14 are bent upwards to form a vertical portion 15, and an opening 16 is provided on the horizontal plate 14 corresponding to the position of the blade, and an opening 16 is provided on the vertical portion 15 to facilitate the screw 4 to pass through. through vias. The screw 4 fixes the blade pressing plate 9 through the through hole, so that the blade pressing plate 9 presses the blade 8 .

[0046] In order to have a better positioning effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com