Cleaning type gas bridge pipe for thermal recovery coke oven

A heat recovery and clean technology, applied in coking ovens, heating of coking ovens, petroleum industry, etc., can solve problems such as incomplete combustion of raw gas, shedding of zirconium-containing ceramic folded blocks, and prolonged coking time of coke, achieving coking time Effects of shortening, reduced load, and low heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

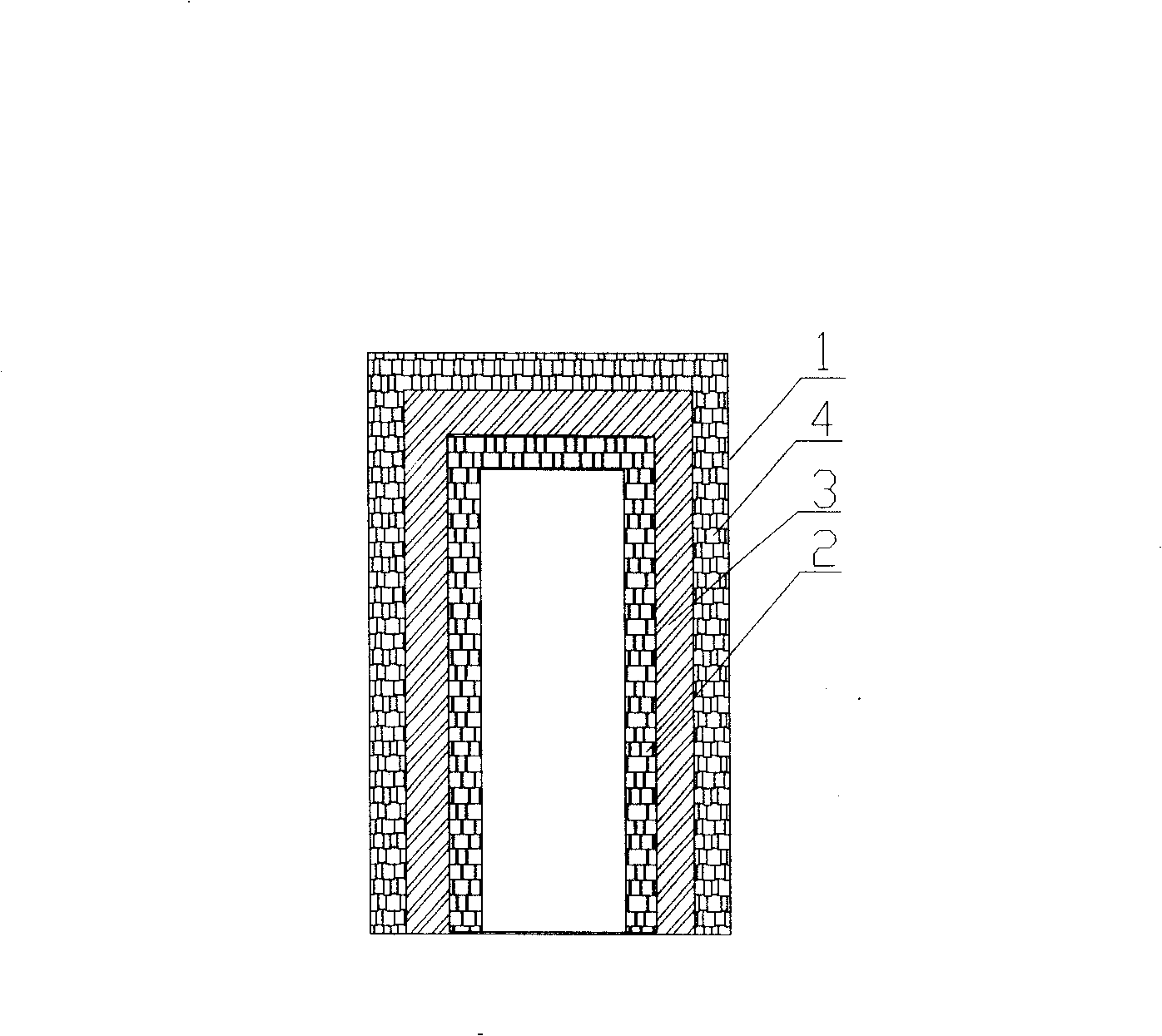

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] As shown in the figure, the clean heat recovery coke oven bridge tube includes an outer shell 1 and an inner lining. The inner lining is composed of a clay brick layer 2, an aluminum silicate thermal insulation felt layer 3 and a perlite brick layer 4, wherein the clay brick layer 2 It is located in the innermost layer of the bridge tube 1. In order to prevent high-temperature smoke from leaking through the brick joints, the clay brick is in the shape of a groove; in order to increase the stability of the bridge tube, a T-shaped clay is used in the middle of the clay brick layer 2 Brick masonry, using overhead brick masonry on its upper part; the aluminum silicate thermal insulation blanket layer 3 is located around the outer surface of the clay brick layer 2, and the perlite brick layer 4 is located between the shell 1 and the aluminum silicate thermal insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com