Diphenylamines substitutedstyrylbiphenyl compounds for preparing blueing material and use thereof

A blue-light material, phenyl vinyl technology, applied in the preparation of amino hydroxyl compounds, luminescent materials, organic compounds, etc., can solve the problems of no patents and literature, few research and reports, etc., and achieve simple reaction and solubility The effect of good and excellent solution processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

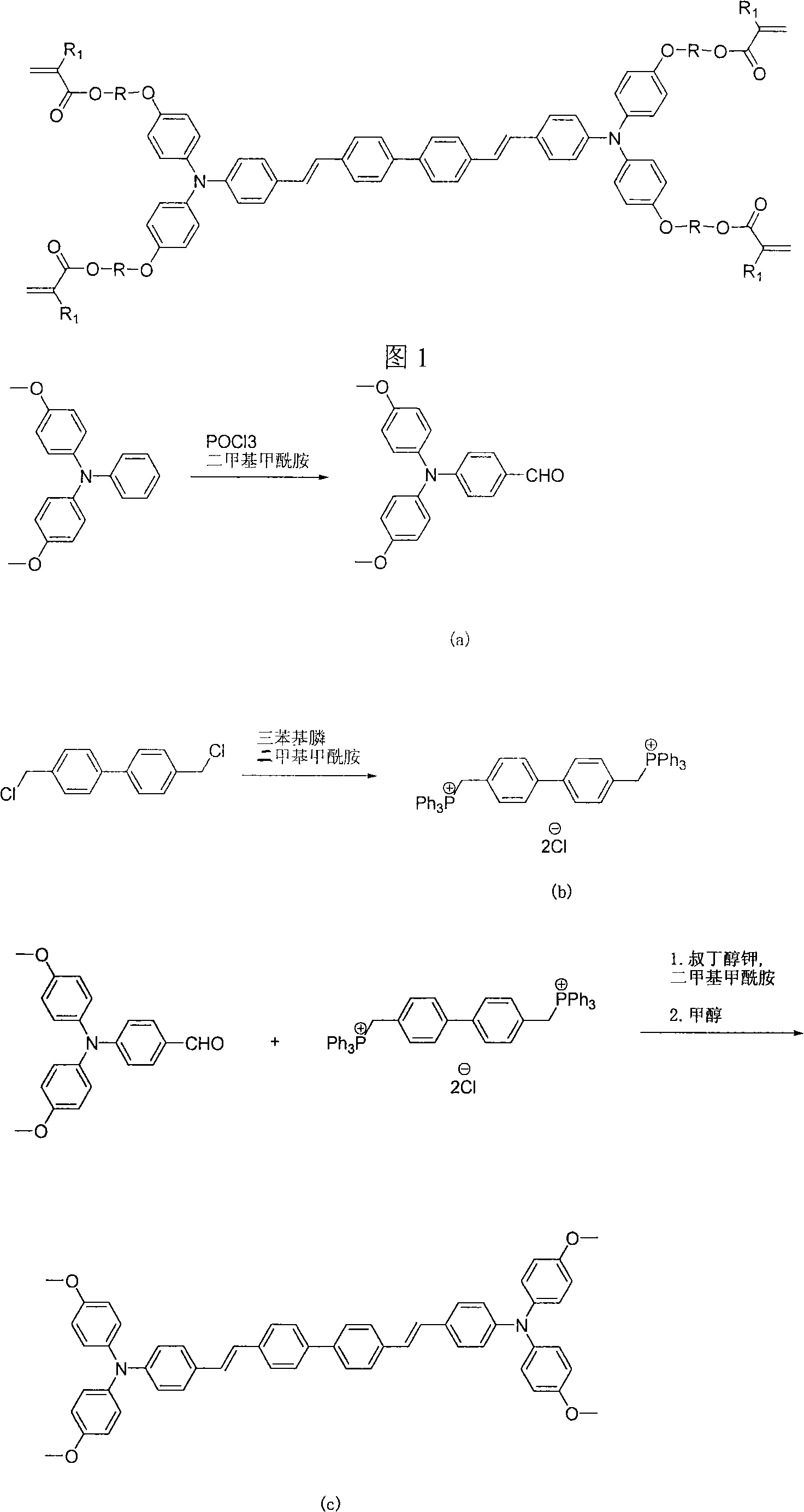

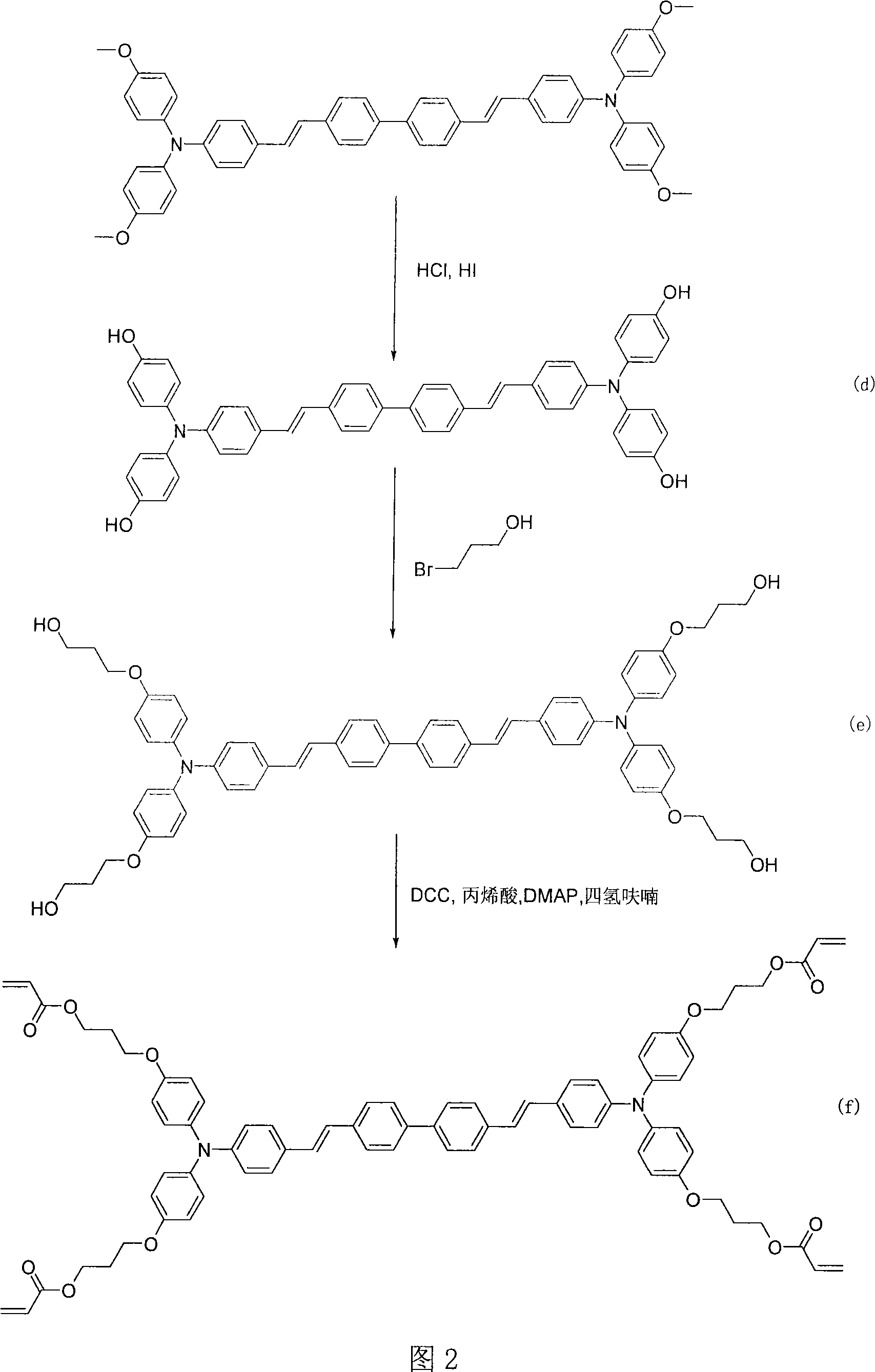

[0036] Embodiment 1. two (oxypropyl diacrylate aniline phenyl vinyl) biphenyl and photocrosslinking cured product are as shown in Figure 2:

[0037] (1) Synthesis of bis(oxypropyl diacrylate aniline phenylvinyl)biphenyl

[0038] Dissolve 18 parts by mass of bis-p-methoxyanilino-p-benzene in 70-100 parts by mass of dry dimethylformamide DMF solvent, and add 8.43-9.97 parts by mass of phosphorus oxychloride POCl dropwise 3 600 parts by mass of dry dimethylformamide solution. Stir at room temperature for 1-2 hr. The reaction liquid was slowly added to 2000 parts of mass ice water, the precipitate was filtered, washed with water, dried, and passed through a silica gel column with a developing agent with a volume ratio of ethyl acetate and benzene of 2:8 to obtain the product (a)—dimethoxyaniline p- 13~15 parts of quality of benzaldehyde.

[0039] Dissolve 25 parts by mass of 4,4'-dichloromethylbiphenyl and 25 to 30 parts by mass of triphenylphosphine in 160 to 200 parts by mass...

Embodiment 2

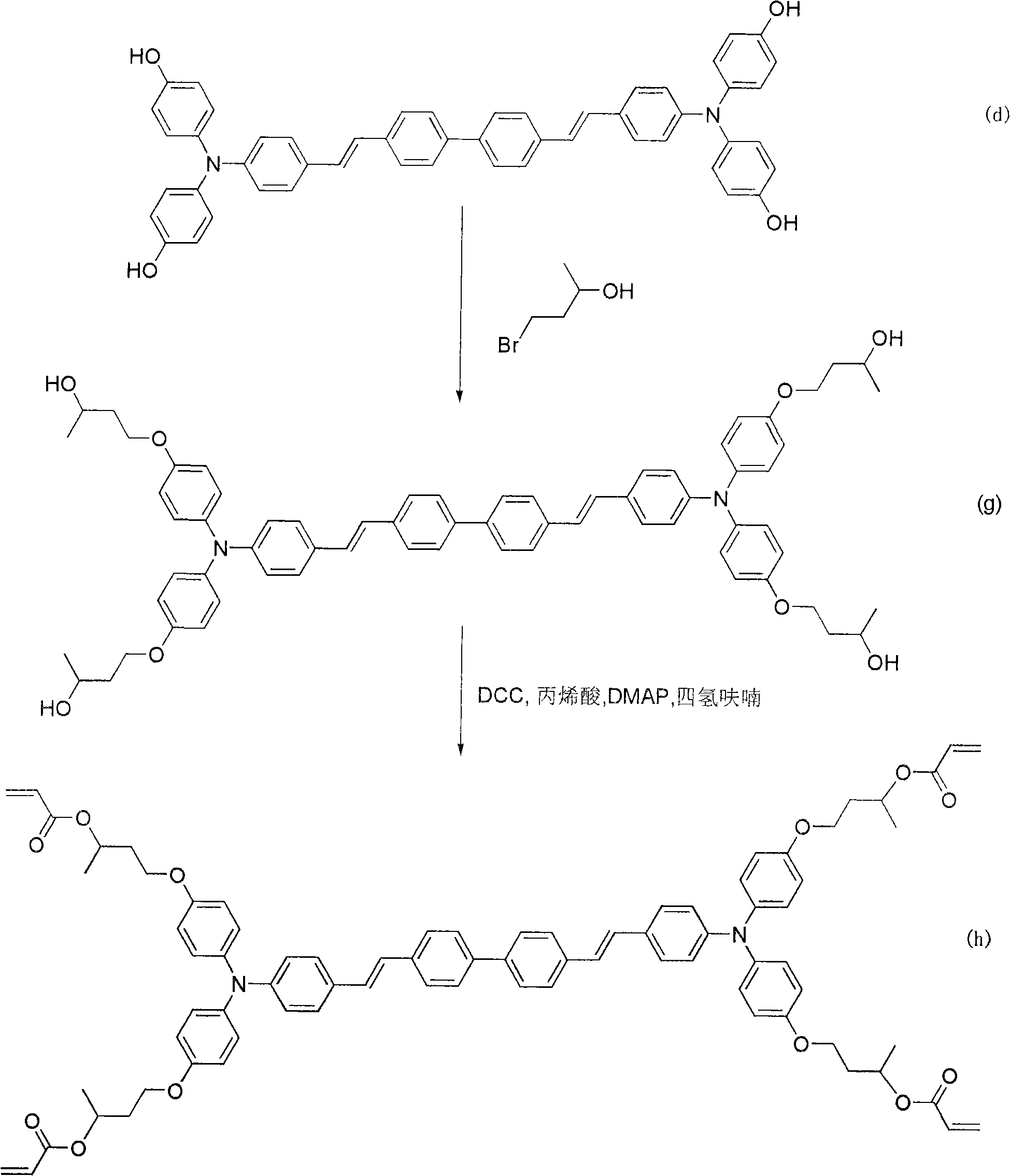

[0049] Embodiment 2. two (oxyisobutyl diacrylate aniline phenyl vinyl) biphenyl and its photocrosslinking cured product

[0050] Such as image 3 Shown:

[0051] (1) Synthesis of bis(oxyisobutyl diacrylate aniline phenylvinyl)biphenyl

[0052] Add K 2 CO 3 (20.7-27.6 parts by mass). After stirring for 12 hours at 50°C, the organic phase was extracted with 500 parts by mass of ethyl acetate and 3000 parts by mass of water, dried over anhydrous magnesium sulfate, filtered, and evaporated to remove the solvent to obtain the product (g)—bis(di-p-hydroxyisobutoxy 13-16 parts of mass of aniline phenyl vinyl) biphenyl.

[0053] Add DCC (21.5 to 22.6 parts mass). Stir at room temperature for 9-11 hours, and then add 2000-3000 parts by mass of water. The organic phase was extracted with ethyl acetate. After evaporating the solvent, use toluene-ethyl acetate (8:2) to pass through a silica gel column to obtain the product (h)——17.5-20 parts by mass of bis(diacrylateoxyisobutylani...

Embodiment 3

[0060] Embodiment 3. bis (oxypentyl dimethacrylate aniline phenyl vinyl) biphenyl and photocrosslinking cured product thereof

[0061] Such as Figure 4 Shown:

[0062] (1) Synthesis of bis(oxypentyl dimethacrylate aniline phenylvinyl) biphenyl

[0063] Add K 2 CO 3 (20.7-27.6 parts by mass). After stirring for 12 hours at 50°C, the organic phase was extracted with 500 parts by mass of ethyl acetate and 3000 parts by mass of water, dried over anhydrous magnesium sulfate, filtered, and evaporated to remove the solvent to obtain the product (i)—bis(di-p-hydroxypentoxy Aniline phenyl vinyl) biphenyl 14 to 17 parts by mass.

[0064] Add DCC ( 21.5 to 22.6 parts by mass). Stir at room temperature for 9-11 hours, and then add 2000-3000 parts by mass of water. The organic phase was extracted with ethyl acetate. After evaporating the solvent, use toluene-ethyl acetate (8:2) to pass through a silica gel column to obtain the product (j)——17.5-20 parts by mass of bis(dimethacryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com