Liquid cement mortar capable of being stored

A cement slurry and liquefaction technology, which is applied in the direction of solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problems of large fluctuations in cement slurry density and affecting the quality of cementing, so as to reduce the cost of cementing and improve the quality of cementing. Cementing efficiency, dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

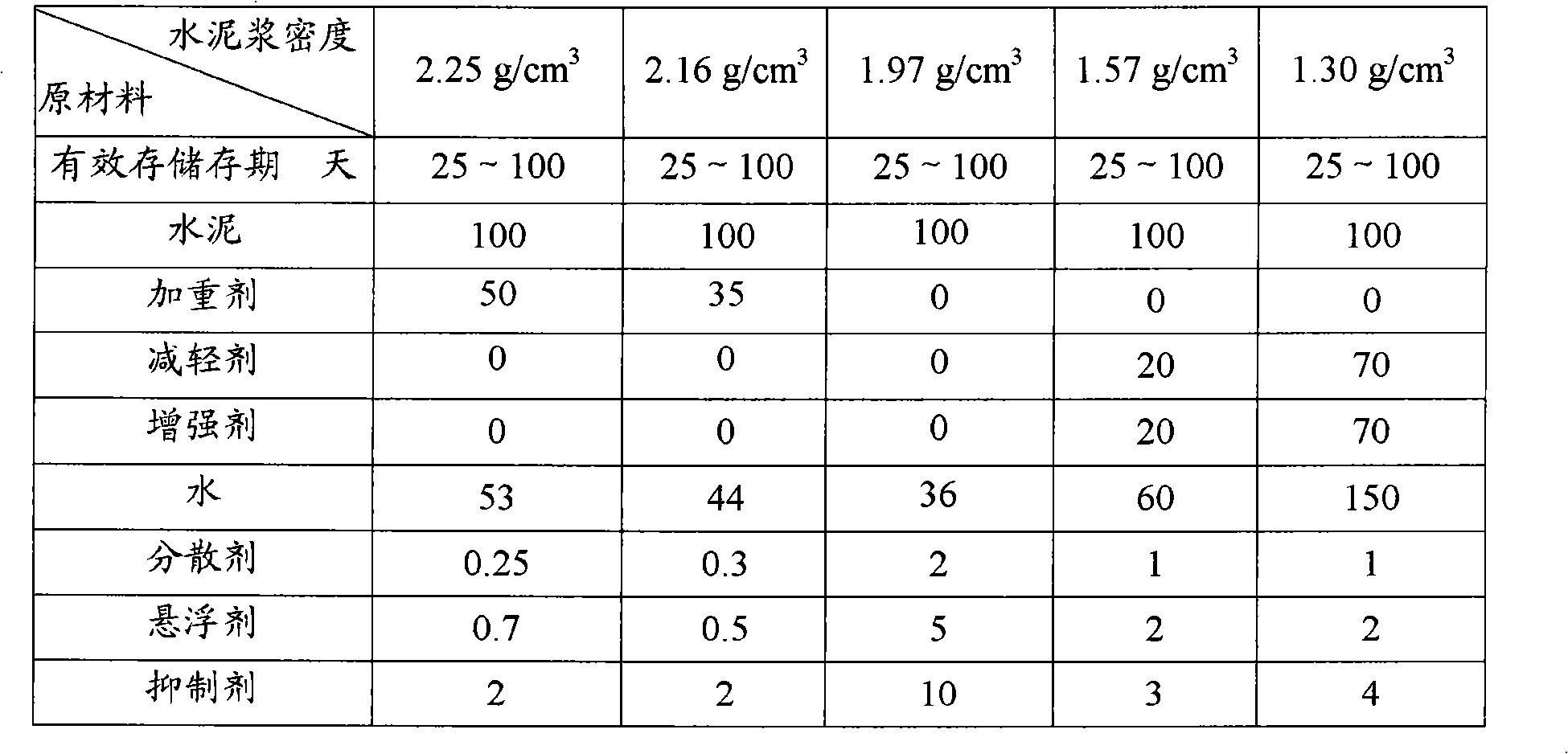

Embodiment 1

[0017] First, weigh each component according to the following ratio: 100 parts of cement, 20 parts of lightening agent, 20 parts of strengthening agent, 60 parts of water, 2 parts of suspension stabilizer, 3 parts of hydration inhibitor and 1 part of dispersant; The stabilizer includes: 1 part of superfine slag powder, 0.2 part of clay, 0.05 part of carboxymethyl cellulose and 0.1 part by weight of xanthan gum; the hydration inhibitor includes: 1 part of gluconate A, 0.2 part of gluconate B , 0.05 lignosulfonate, 1 part of phosphonate, 0.2 part of soluble starch; lightening agent includes: 1 part of floating beads, 0.1 part of expanded perlite, 0.5 part of clay; strengthening agent includes: 1 part of ultrafine cement, 1 part Part microsilica, 0.1 part aluminum sulfate, 0.3 part sulfonated ketone aldehyde condensate; dispersant includes: 1 part sulfonated ketone aldehyde condensate, 0.1 part sulfonated melamine concentrate, 0.3 part naphthalene sulfonate polymer, 0.05 part Sty...

Embodiment 2

[0022] First weigh each component according to the following ratio: 100 parts of cement, 35 parts of weighting agent, 44 parts of water, 0.5 part of suspension stabilizer, 2 parts of hydration inhibitor and 0.3 part of dispersant; wherein, the suspension stabilizer includes: 1 1 part ultrafine slag powder, 0.5 part clay, 0.2 part carboxymethyl cellulose and 0.01 part xanthan gum; hydration inhibitors include: 1 part gluconate A, 0.8 part gluconate B, 0.15 part lignosulfonic acid Salt, 0.1 part of phosphonate, 0.01 part of soluble starch; strengthening agent includes: 1 part of superfine cement, 1 part of micro silicon, 0.5 part of aluminum sulfate, 0.1 part of sulfonated ketone-aldehyde condensate; dispersing agent includes: 1 part of sulfonated Keto-aldehyde condensate, 0.6 part sulfonated melamine concentrate, 0.6 part naphthalene sulfonate polymer, 0.7 part styrene maleic anhydride polymer, and 0.2 part sulfamate polymer; weighting agents included as: 1 part hematite Minera...

Embodiment 3

[0026] First, weigh each component according to the following ratio: 100 parts of cement, 36 parts of water, 5 parts of suspension stabilizer, 10 parts of hydration inhibitor and 2 parts of dispersant; wherein, the suspension stabilizer includes: 1 part of ultrafine slag powder , 0.3 parts of clay, 0.1 parts of carboxymethyl cellulose and 0.05 parts of xanthan gum; hydration inhibitors include: 1 part of gluconate A, 0.6 parts of gluconate B, 0.1 part of lignosulfonate, 0.5 parts of carboxy salt, 0.1 part soluble starch; dispersants include: 1 part sulfonated ketone aldehyde condensate, 0.1 part sulfonated melamine concentrate, 0.4 part naphthalene sulfonate polymer, 0.3 part styrene maleic anhydride polymer and 0.5 part Sulphamate polymer.

[0027] The rest of the preparation process and storage are the same as in Example 1.

[0028] The storable cement slurry prepared with the above ratio has a density of 1.97g / cm 3 , the storage period reaches 25-100 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com