Water press large-pressure instant load-missing control method

A control method and technology of hydraulic presses, applied in electric fluid pressure control, metal processing equipment, etc., to achieve smooth unloading, improve production efficiency and reduce severe impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

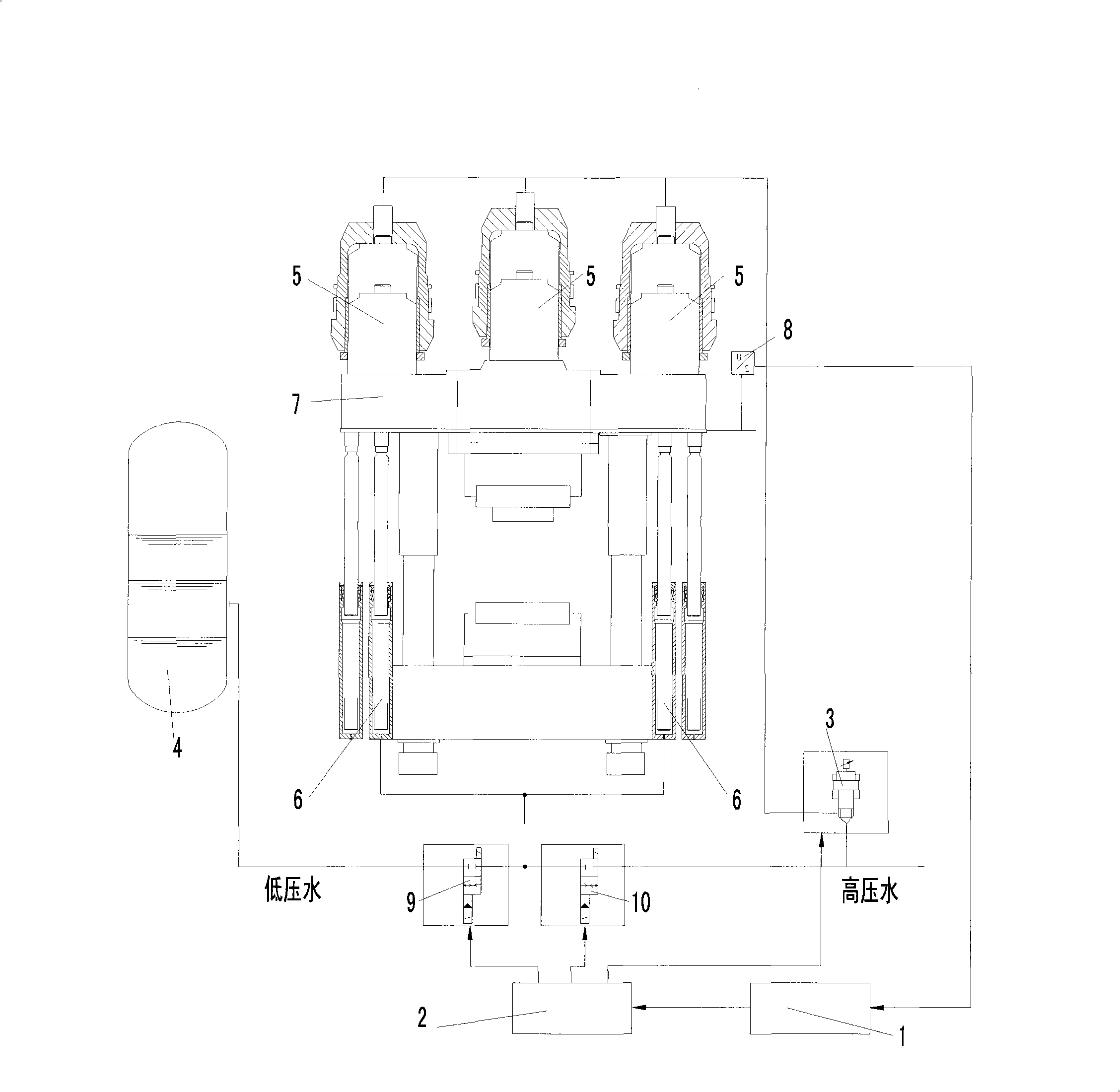

[0013] The specific embodiment of the present invention is shown in the attached drawings. The hydraulic press includes a main working cylinder 5, a main working cylinder control valve (proportional valve) 3, a movable beam 7, a return cylinder 6, a return cylinder low pressure water control valve 9, and a return stroke Cylinder high pressure water control valve 10, programmable controller 1, executive control element (amplifier) 2, displacement sensor 8 and pipelines. The said hydraulic press high pressure instantaneous load loss control method is the hydraulic buffer pad method. When the hydraulic press has a high pressure instantaneous load loss, the return cylinder 6 is controlled to connect to high pressure water, so that the return cylinder 6 and the pipeline form a hydraulic buffer pad to buffer the movable beam 7 , Relieve pressure and absorb excess energy. Specific steps are as follows:

[0014] A. When punching starts, cut off the return cylinder low-pressure water con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com