Both-side driven rotary tillage soil-working machine

A technology of leveling machine and transmission box, which is applied in the fields of tillage equipment, transmission device, differential transmission device, etc., can solve the problems of increasing the torque of the side plate end of the knife roller, the easy bending and breaking of the knife roller, and the poor gluing performance of the gear, etc. The effect of good meshing performance, small machine vibration and balanced torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

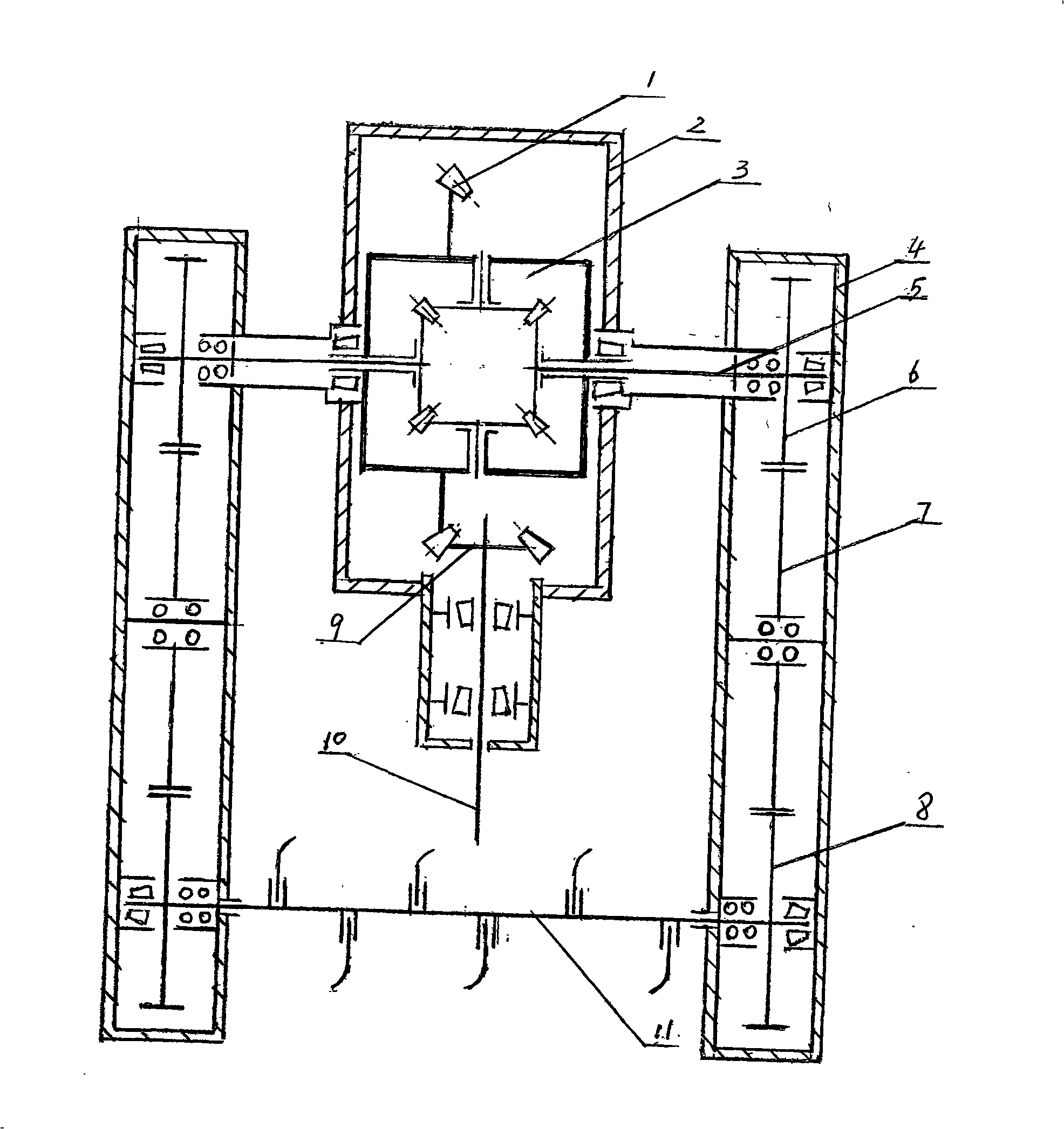

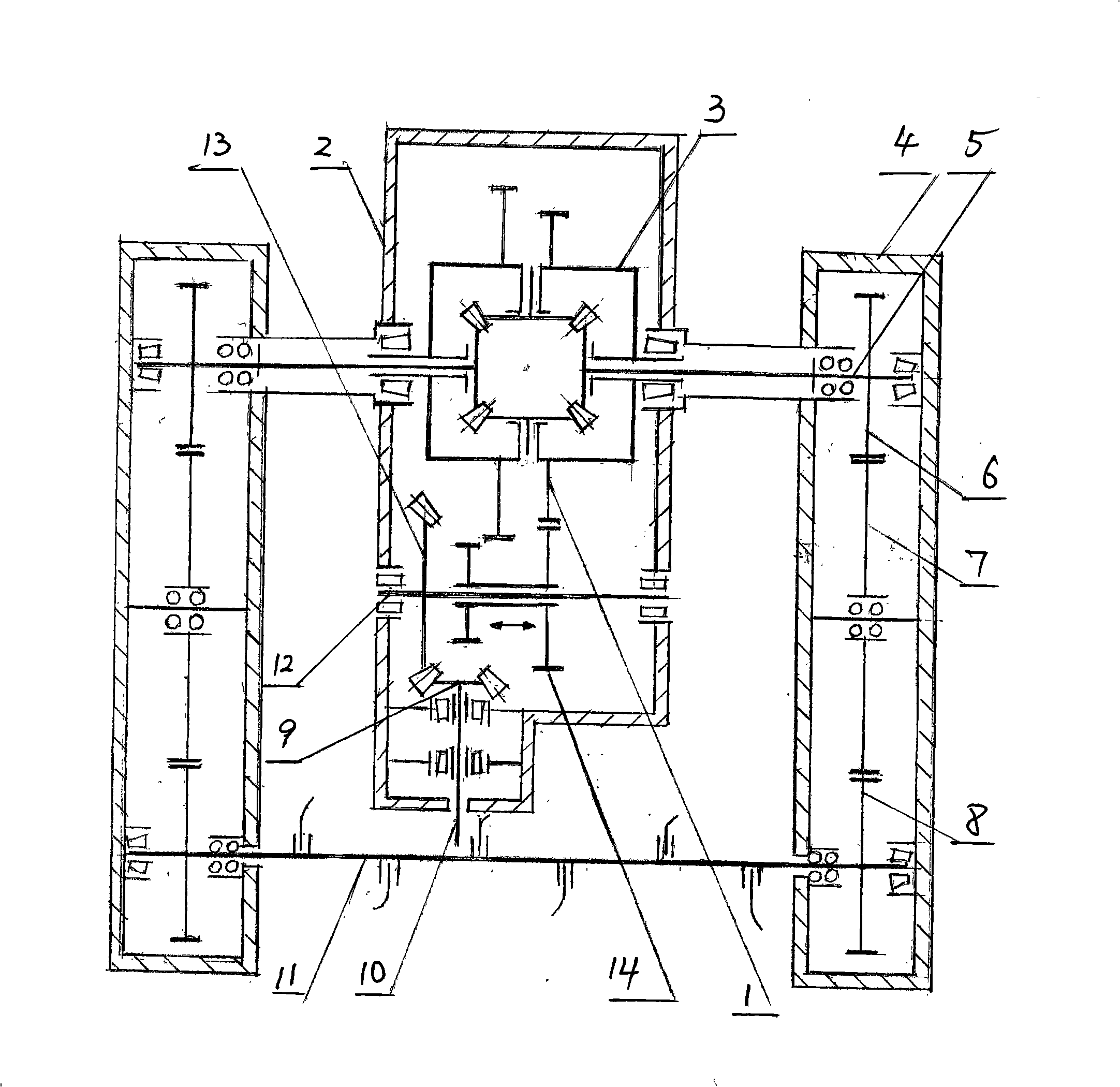

[0013] A two-sided transmission rotary tillage soil preparation machine, comprising a transmission assembly and a knife roller assembly 11. The transmission assembly includes a middle transmission box 2 and two left and right side transmission boxes 4 connected with the rear power output of the tractor through a universal joint. A pair of large and small bevel gears meshing with each other in the intermediate transmission box 2, the small bevel gear 9 is mounted on the power input shaft 10, the power input shaft 10 is connected with the rear power output of the tractor through a universal joint, and the large bevel gear is fixed in a differential The transmission gear 1 on the housing of the speed gear 3, the differential gear 3 is equipped with four bevel gears that mesh with each other perpendicularly, and the left and right bevel gears of the differential gear 3 are splined to one end of the left and right output shafts 5. The output half shafts 5 on both sides of the speed gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com