High-strength hot-dip zinced steel sheet excellent in moldability and suitability for plating, high-strength alloyed hot-dip zinced steel sheet, and processes and apparatus for producing these

一种热浸镀锌钢板、高强度钢板的技术,应用在热浸镀工艺、化学仪器和方法、制造工具等方向,能够解决不能充分确保镀覆密合性、空间不能采用、没有各种性能提高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

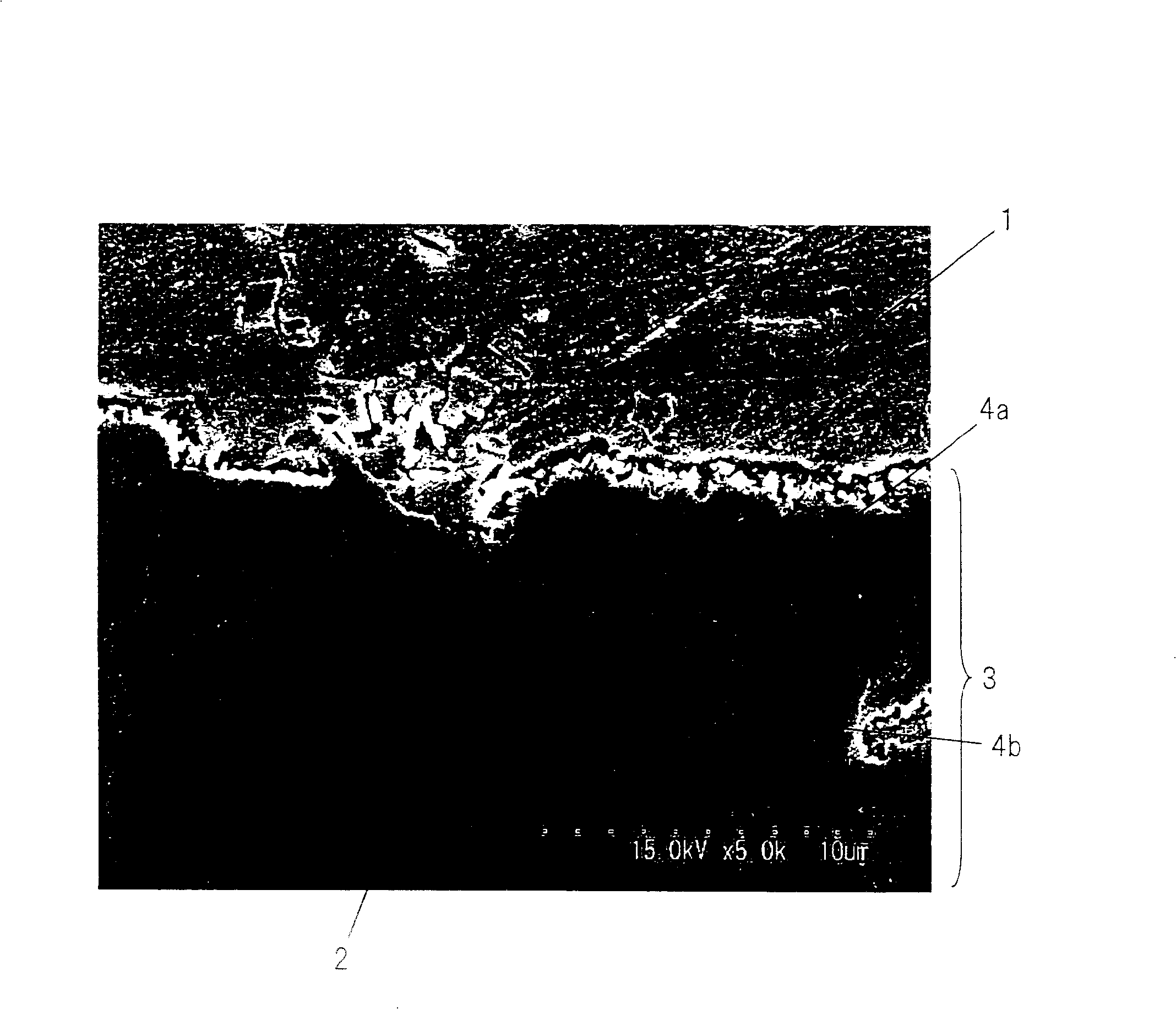

Embodiment 1

[0182] A slab having the composition in Table 1 was heated to 1423K, rolled at a finish rolling temperature of 1183K to 1203K to form a 4.5mm hot-rolled steel strip, and coiled at 853K to 953K. After pickling, cold rolling is carried out, and after being rolled into a 1.6mm cold-rolled steel strip, the continuous hot-dip galvanizing equipment of the annealing method in the production line is used to perform coating under the conditions shown in Table 2 to form an alloyed hot-dip galvanizing equipment. Galvanized steel. As a continuous hot-dip galvanizing facility, after heating in a non-oxidizing furnace, reduction and annealing are performed in a reduction zone. Adjust the combustion air ratio of the non-oxidizing furnace to 1.0 and use it as an oxidation zone. The reduction belt is installed there for making a mixture of CO and H 2 The gas combustion and introduction of H produced 2 O.CO 2 device, the H 2 O and CO 2 introduced to contain 10 vol% H 2 N 2 in the gas. ...

Embodiment 2

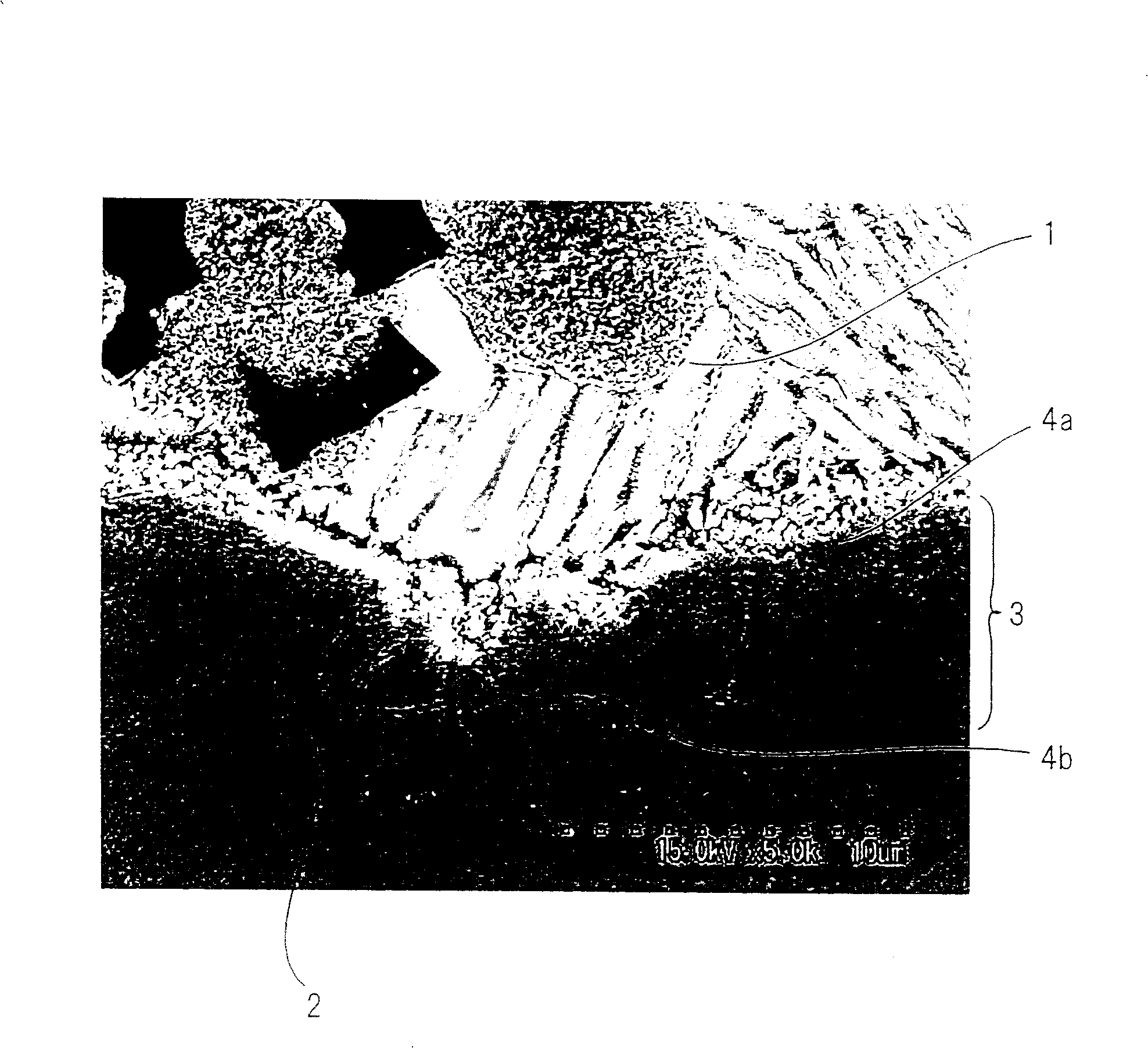

[0212] A slab having the composition in Table 1 was heated to 1423K, rolled at a finish rolling temperature of 1183K to 1203K to form a 4.5mm hot-rolled steel strip, and coiled at 853K to 953K. After pickling, cold rolling is carried out, and after being rolled into a 1.6mm cold-rolled steel strip, the continuous hot-dip galvanizing equipment of the annealing method in the production line is used to perform the coating under the conditions shown in Table 3 to form alloyed hot-dip galvanizing equipment. Galvanized steel. As a continuous hot-dip galvanizing facility, after heating in a non-oxidizing furnace, reduction and annealing are performed in a reduction zone. The dew point of the area heated by the non-oxidizing furnace and its residual heat is adjusted to 283K, and it is used as an oxidation zone. The reduction belt is installed there for making a mixture of CO and H 2 The gas combustion and introduction of H produced 2 O.CO 2 device, the H 2 O and CO 2 introduced ...

Embodiment 3

[0241] A slab having the composition shown in Table 1 was heated to 1423K, rolled at a finish rolling temperature of 1183K to 1203K to form a 4.5mm hot-rolled steel strip, and coiled at 853K to 953K. After pickling, cold rolling is carried out, and after being rolled into a 1.6mm cold-rolled steel strip, the continuous hot-dip galvanizing equipment of the annealing method in the production line is used to carry out the coating under the conditions shown in Table 4 to form alloyed hot-dip galvanizing equipment. Galvanized steel. As a continuous hot-dip galvanizing facility, after heating in a non-oxidizing furnace, reduction and annealing are performed in a reduction zone. The dew point of the area heated by the non-oxidizing furnace and its residual heat is adjusted to 283K, and a device for mixing CO and H is installed in the reduction zone. 2 The gas combustion and introduction of H produced 2 O.CO 2 device, the H 2 O and CO 2 introduced containing 10 vol% H 2 N 2 In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com