Wire sheath construction of movable accessory and manufacturing method thereof

A technology for accessories and wire sleeves, applied in the field of mobile accessories wire sleeve structure and its manufacturing method, can solve the problems of easy to hide dirt, limited tensile effect, difficult to step into the class of high-quality products, etc. The effect of removing dirt, improving the service life, and having great industrial utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

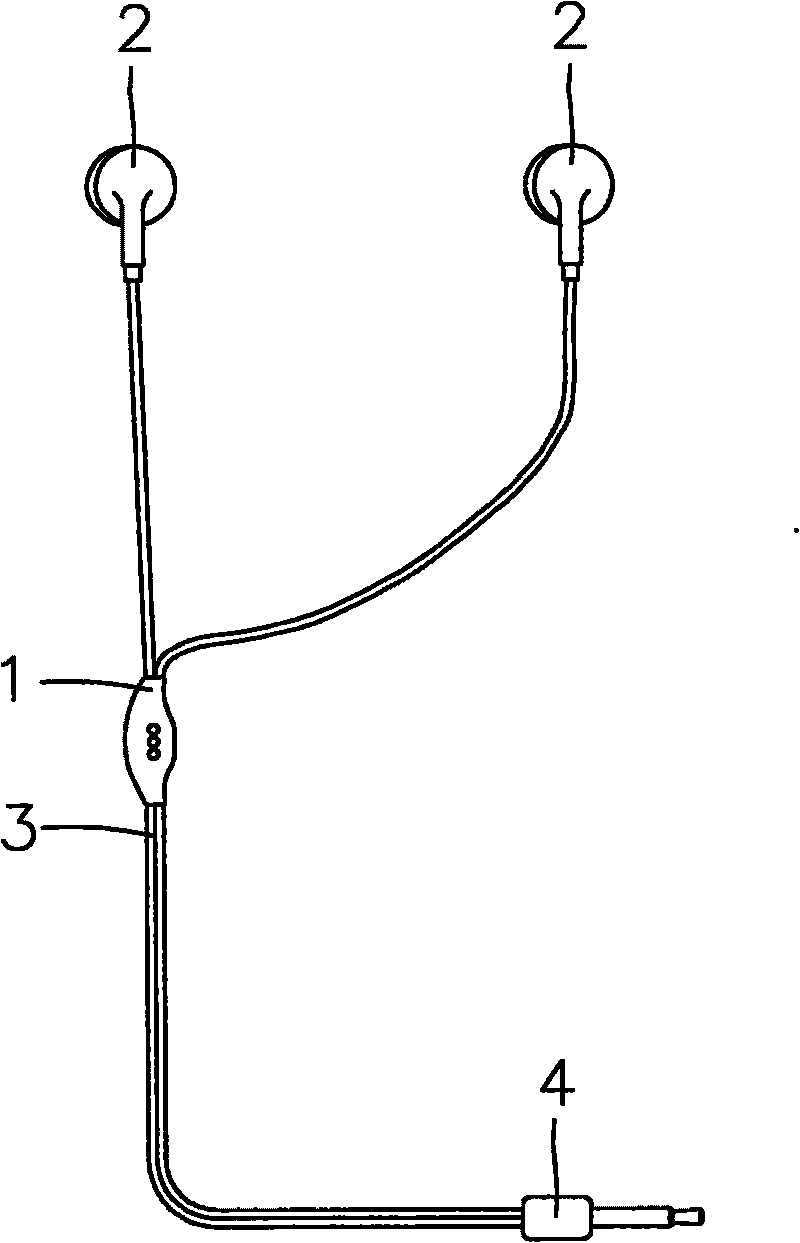

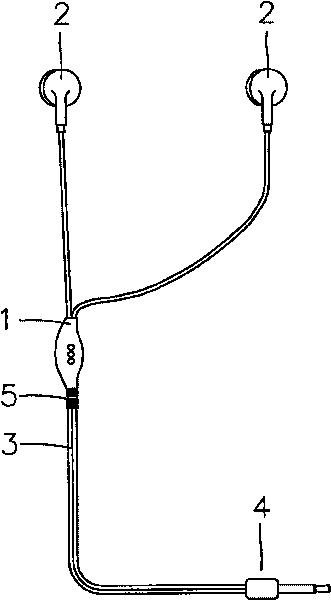

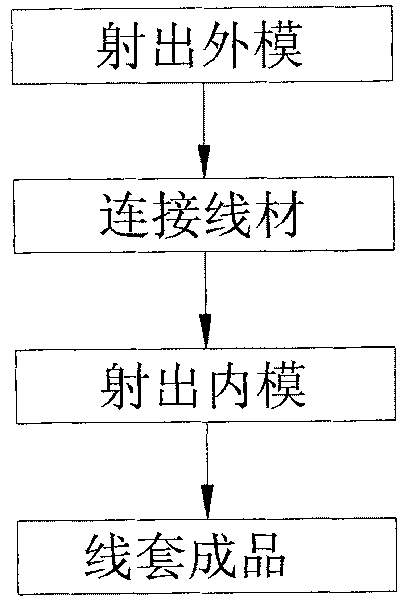

[0044] refer to image 3 , is the production flow chart of the first embodiment of the wire cover of the mobile accessory of the present invention. The mobile accessory 90 in this embodiment is implemented as a microphone, so it will be represented as a microphone wire cover in the following. The manufacturing process of the line cover of the mobile accessory 90 is carried out according to the following steps.

[0045] Injecting the outer mold: first, inject an outer mold 10 structure in the mold, refer to Figure 4 and Figure 5 The shape of the outer mold 10 is trumpet-shaped, one end of which is concavely provided with a joint portion 11 , and the outer mold 10 is also provided with a notch 12 on one side of the joint portion 11 .

[0046] On the contrary, the outer mold 10 forms an elongated extens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com