An acidic gold alloy plating solution

A plating solution and alloy technology, applied in the field of acidic gold alloy plating solution, can solve problems such as burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0031] A gold-cobalt plating solution consisting of the following substances was prepared as a base bath.

[0032] Potassium cyanide gold (I) 15g / L (10g / L gold)

[0033] Basic cobalt carbonate 1.16g / L (0.5g / L cobalt)

[0034] Tripotassium citrate monohydrate 116g / L

[0035] Citric anhydride 66.11g / L

[0036] Hexamethylenetetramine 0.5g / L

[0037] Water (deionized water) balance

[0038] The pH value of the above plating solution was adjusted to 4.3 with potassium hydroxide.

Embodiment 1

[0040] The gold-cobalt plating bath in Example 1 was prepared by adding 0.5 g / L nicotinic acid (3-pyridinecarboxylic acid) as a brightener before adjusting the pH value of the above basic bath, and then adjusting the pH value to 4.3.

Embodiment 2-8

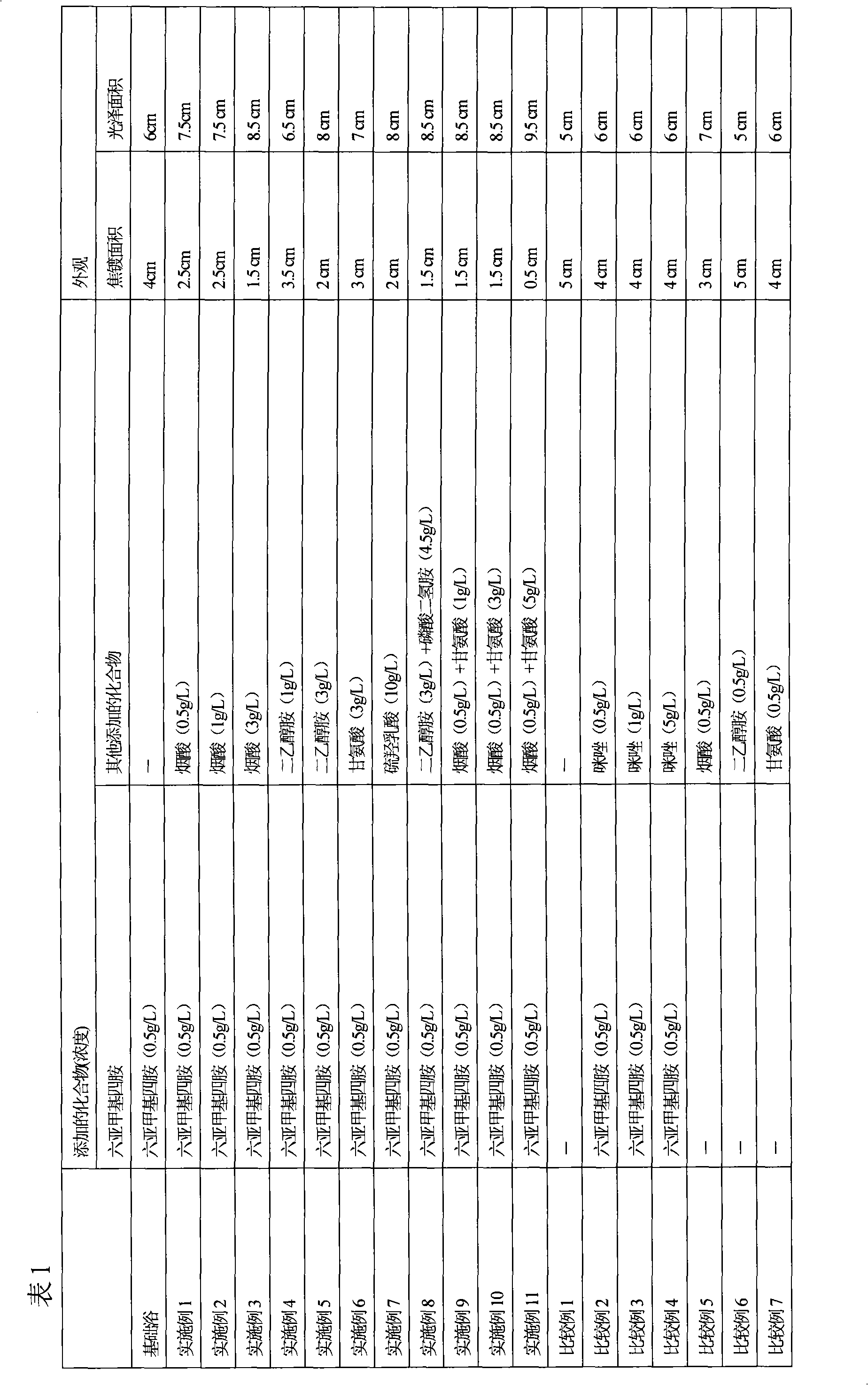

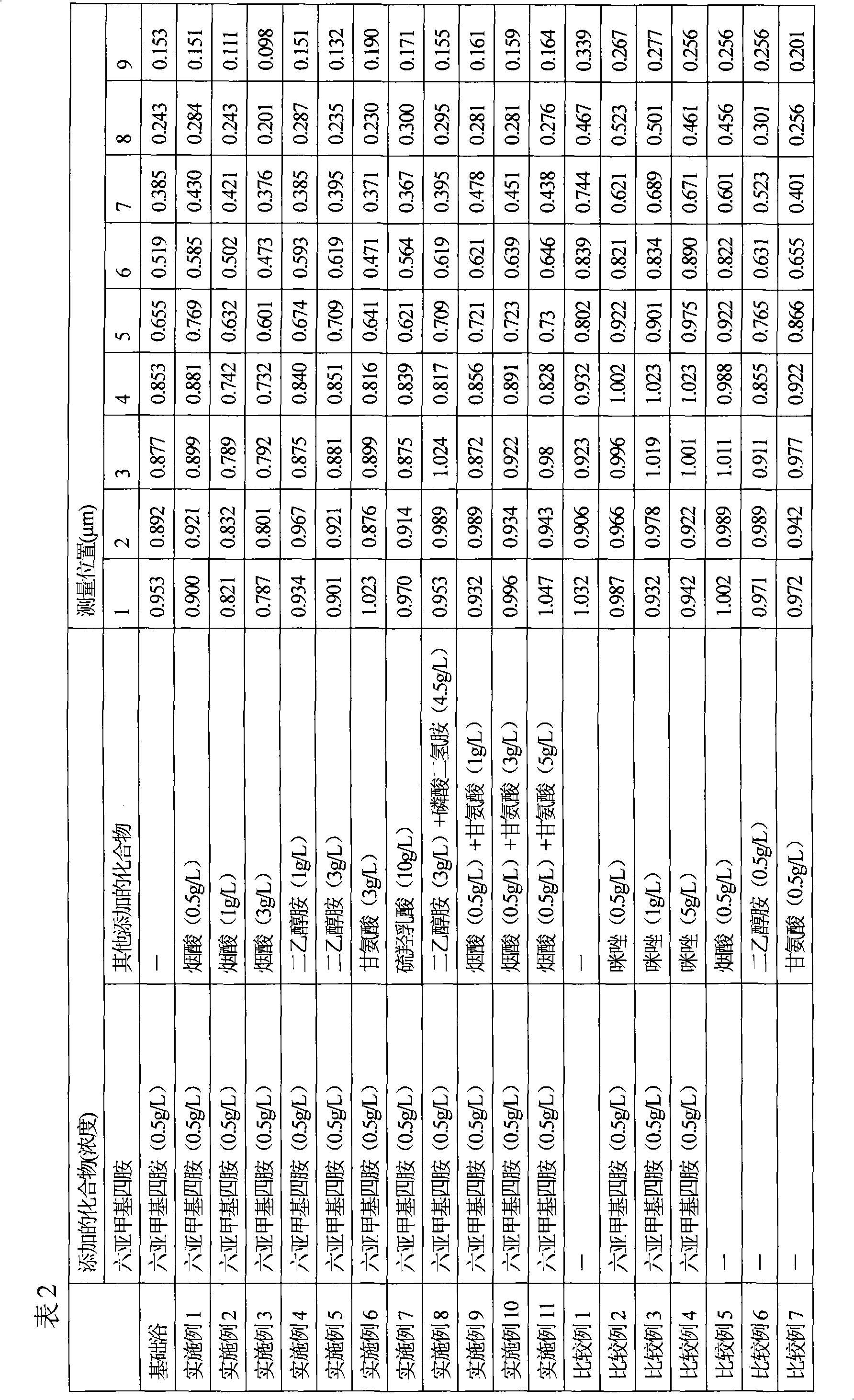

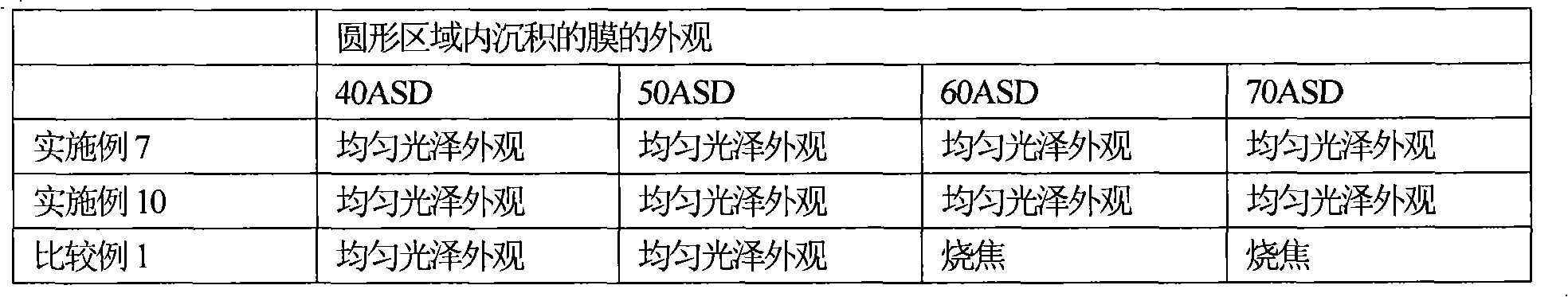

[0042] The preparation of the gold-cobalt plating solution was similar to that of Example 1, except that the compounds shown in Table 1 below were added in the indicated concentrations instead of nicotinic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com