Processing and refining method of copper-containing raw material

A refining method and technology of raw materials, applied in the field of processing and refining copper-containing raw materials, can solve the problems of difficulty in removing impurities, high transfer efficiency, and difficulty in removing antimony, etc., and achieve the effects of improving recovery rate, reducing losses, and reducing transportation costs

Inactive Publication Date: 2010-12-01

JX NIPPON MINING & METALS CORP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

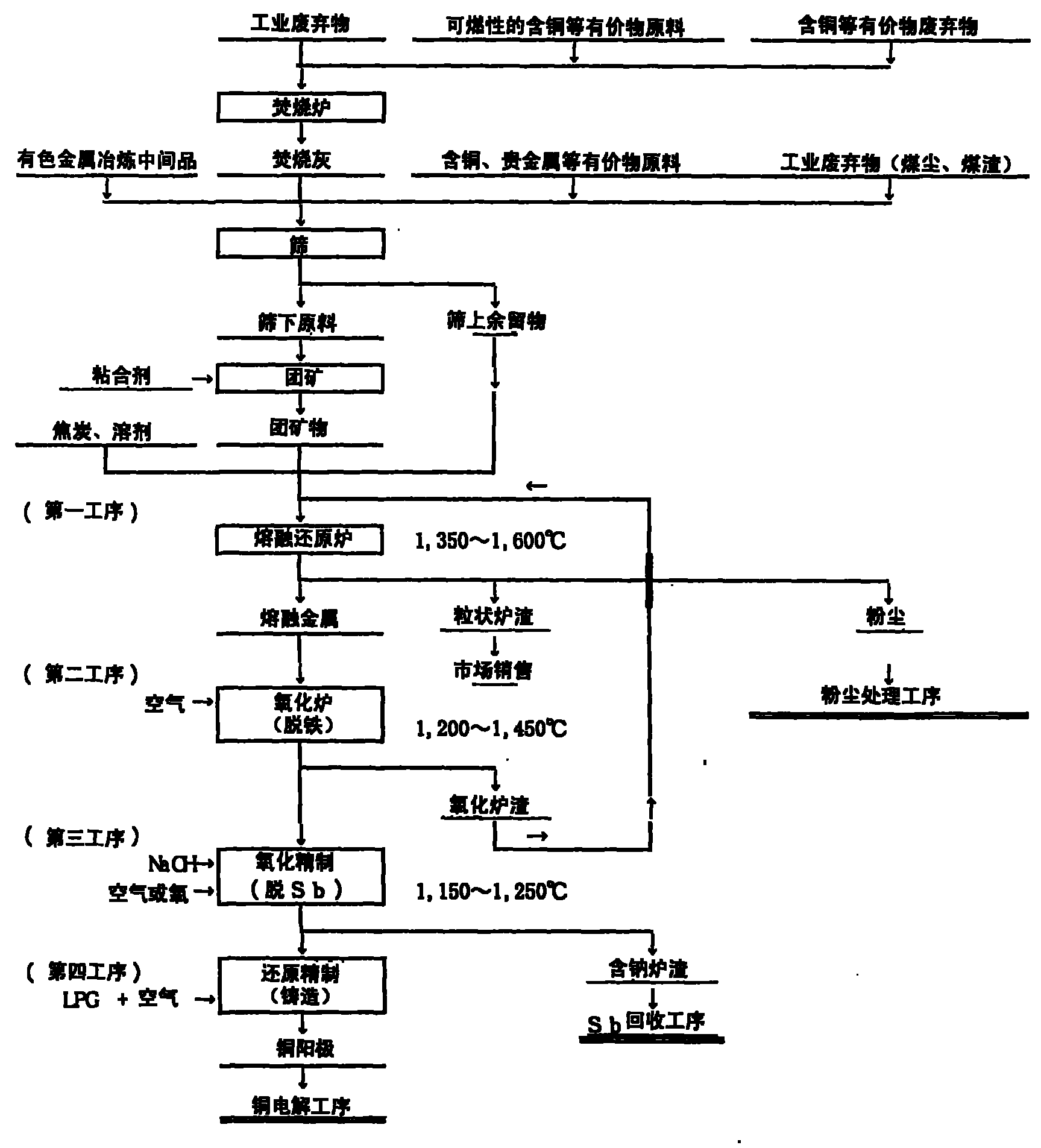

It is relatively easy to use oxygen-containing air to remove copper, precious metals, iron, zinc, lead, etc. in impurities other than nickel, but it is difficult to remove antimony. If it is necessary to obtain blister copper that reaches the copper anode grade, nickel or The transfer efficiency of valuable metals such as precious metals to slag becomes high and it is difficult to effectively remove impurities

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

Embodiment 6-7、 comparative example 3-4

Embodiment 8、9

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

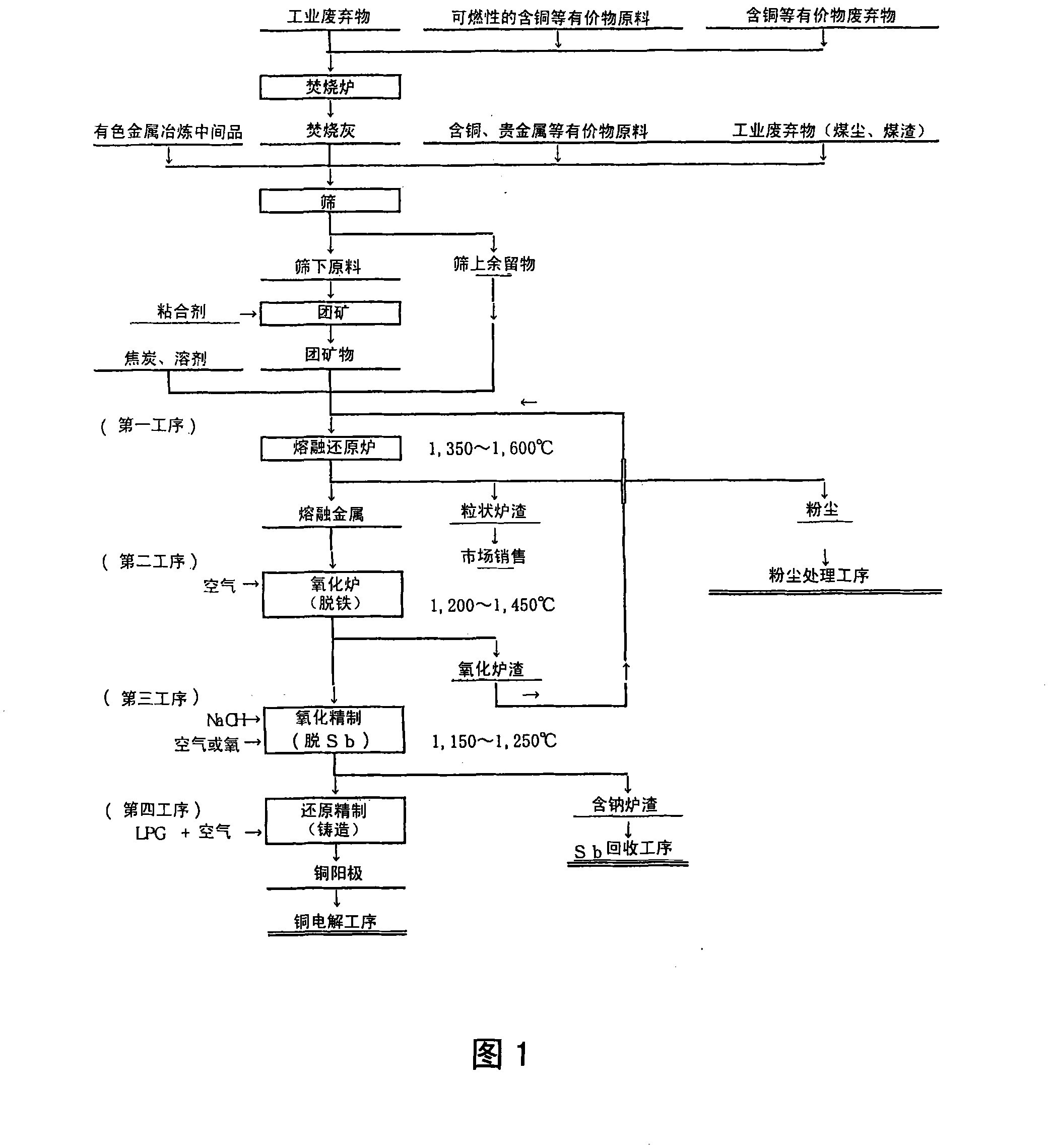

The objective of the invention is to provide a method for processing and refining copper and material containing copper with high quality and efficiency from industrial waste, valence waste containing copper. The method for processing and refining materials containing copper at least includes: melting and reducing valence materials containing copper, noble metal, nickel, Fe, Sb with solvent and coke in a coke bed furnace of a straight-up furnace, a first working procedure of separating melt metal containing Cu and Fe as main components with slag containing calcium oxide, silicon dioxide, alumina and ferric oxide as main components, and a second working procedure of taking out melt metal generated in the first working procedure to a calcar of next working procedure, adding calcium carbonate into the melt metal in the calcar, insufflating gas containing O2 to the melt metal, making main impurities, such as Fe, and the like into slag, and taking out from the furnace.

Description

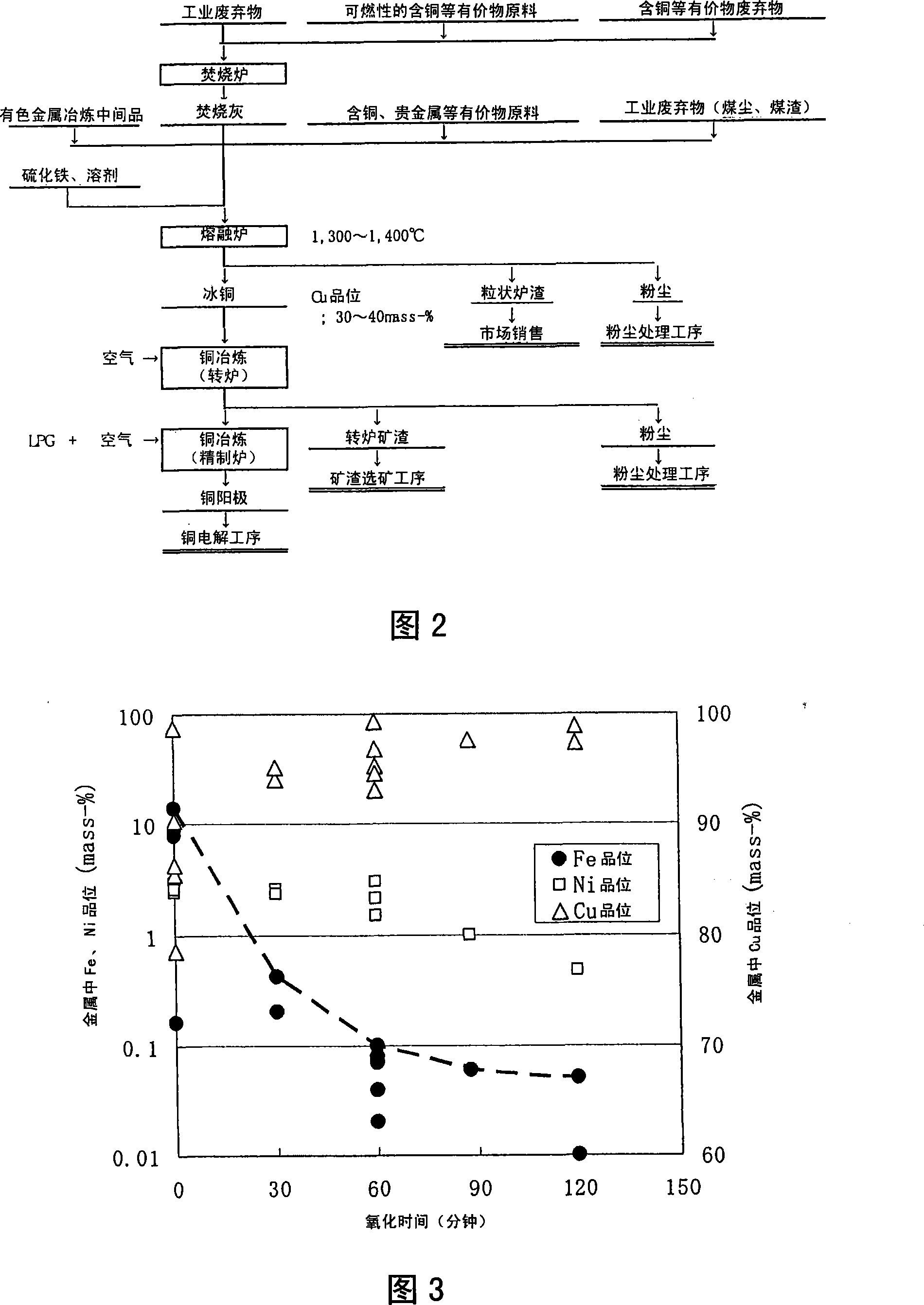

Method for processing and refining copper-containing raw materials Technical field The present invention relates to an incineration ash that can be obtained from industrial wastes, wastes containing valuables such as copper, incineration of combustible valuable raw materials containing copper, precious metals, nickel, iron, antimony, etc., or containing copper and precious metals , Nickel, iron, antimony and other valuable raw materials, copper-containing intermediate raw materials produced from the non-ferrous metal smelting process, a processing method to recover refined copper. Background technique In the past, in reverberatory furnace type smelting furnaces, industrial wastes, wastes containing valuables such as copper, and combustible valuable raw materials containing copper, precious metals, nickel, iron, and antimony were melted together with iron sulfide. The obtained incineration ash or valuable raw materials containing copper, precious metals, iron, nickel, antimony,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B15/14

CPCY02P10/20

Inventor 冈本秀则佐佐木康胜副浩二

Owner JX NIPPON MINING & METALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com