Repairing method for cooling staveleakage

A repair method and technology of cooling wall, applied in cooling devices, coatings, arc welding equipment, etc., can solve the problems of reduced thermal conductivity and cooling capacity, inability to repair large cracks, etc., and achieve the effect of restoring the cooling function and reducing the repair cost.

Inactive Publication Date: 2010-12-01

SHANGHAI MEISHAN IRON & STEEL CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It mainly solves the technical problems that grouting plugging cannot repair large cracks and the heat conduction and cooling capacity decreases after grouting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

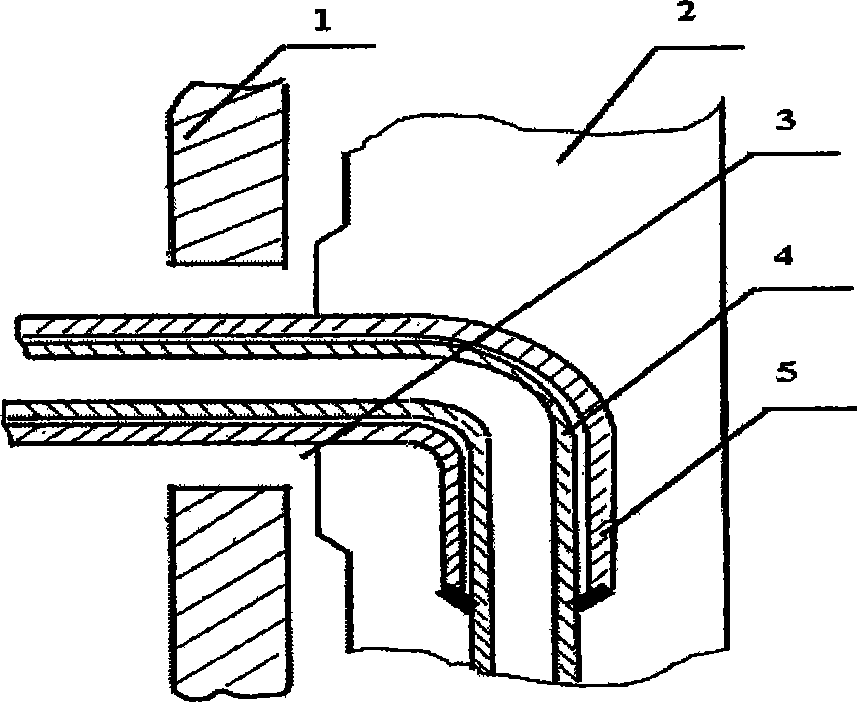

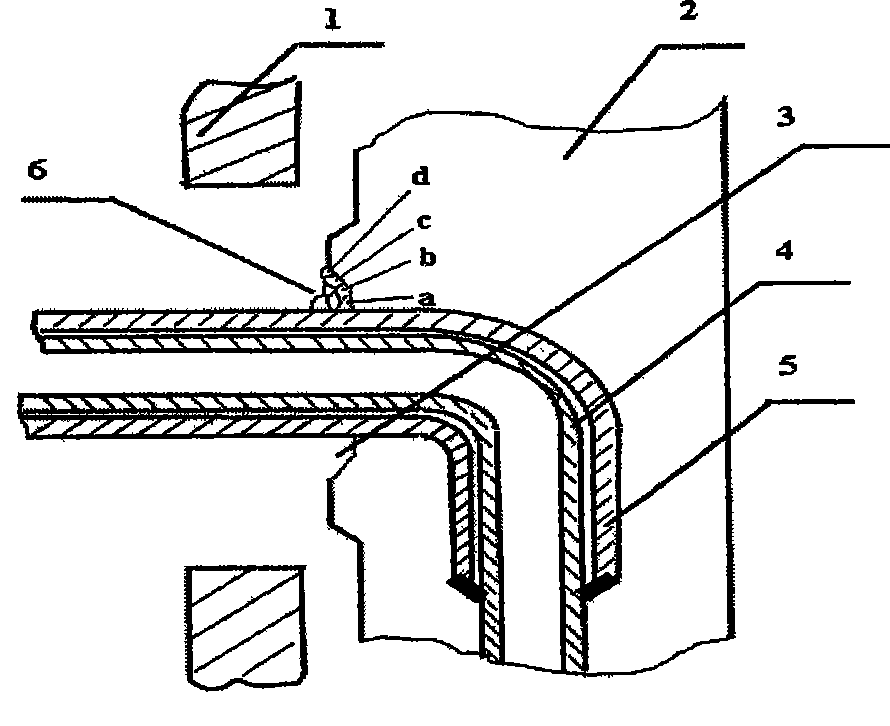

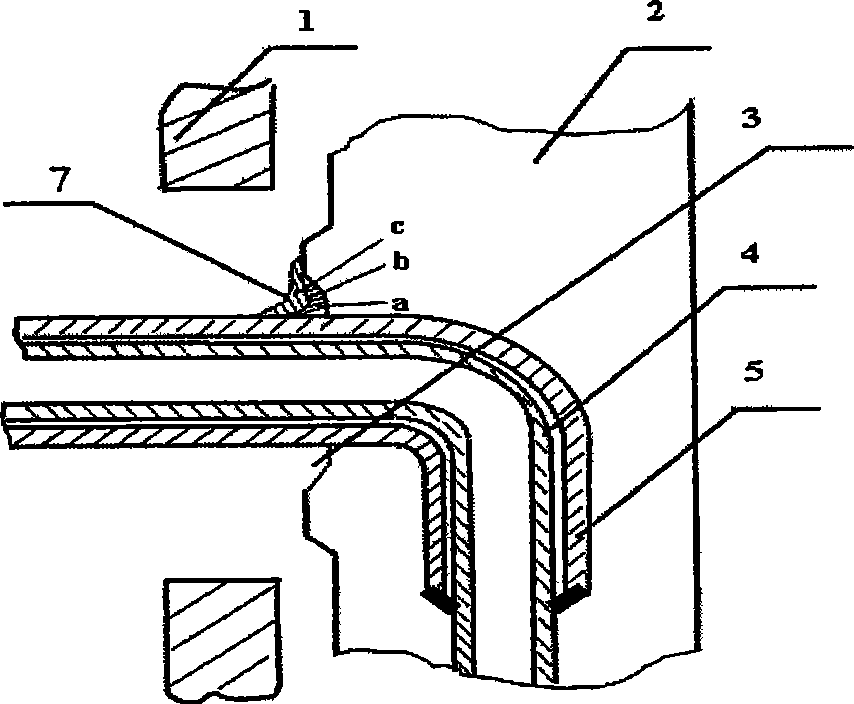

The invention belongs to a repairing method of iron-making blast furnace equipment, which relates to a cooling wall leakage repairing method. The method mainly solves the technical problems that grouting can stop leakage but can not repair big gaps and the conduction cooling capacity is reduced after grouting. The repairing method of cooling wall leakage is characterized in that the method comprises the following steps of: a. shell opening: including opening holes with apertures of 150 to 250mm on the furnace shell around water pipes on a cooling wall; b. root grooving: including opening grooves at the root part of the cooling wall around the leaking water pipes and sheaths for eliminating cracks as well as molding sand, slag inclusion and loosening on the surface of the cooling wall; c. surface pretreatment: comprising eliminating the grooving parts and residual oxidative metal and oxide films on the surface around the grooves for exposing the metallic luster; d. leakage repairing: the leakage repairing method includes one process of a welding process and a high-molecular polymeric metal bonding process or a composite process combining the two processes; and e. hydrostatic test: after the repairing work, water is supplied for testing the pressure for 30min so as to check the leakage condition. The method is mainly used for repairing cooling wall leakage of blast furnaces.

Description

Stave leakage repair method Technical field: The invention belongs to a method for repairing ironmaking blast furnace equipment, and in particular relates to a method for repairing leakage of cooling walls in service. Background technique: The cooling stave is one of the main components of the ironmaking blast furnace. It is installed between the furnace shell and the furnace lining to block the heat transfer from the high temperature in the furnace to the furnace shell and prevent the high temperature deformation of the furnace shell. The stave is integrally cast with a built-in S-shaped seamless steel pipe, and the single weight is generally more than 1.3 tons. After the stave has been used for a long time, due to casting defects of the stave or the fluctuation of the smelting strength of the blast furnace, high temperature cold and hot vibration, etc., there will often be a certain displacement between the stave and the furnace shell. Leakage of cooling water in the st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21B7/10B23K9/04B05D7/24

Inventor 王孝建董汉君王布林史文杰尹洪顶

Owner SHANGHAI MEISHAN IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com