Pipeline leakage checking and blocking technology on iron-blast furnace cooling wall

A technology for cooling walls and water pipes, applied in cooling devices, inspection devices, etc., can solve the problems of inability to quantitatively determine the degree of water leakage, inability to continue to use, low efficiency, etc., and achieve the effect of fast speed, recovery of cooling function, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

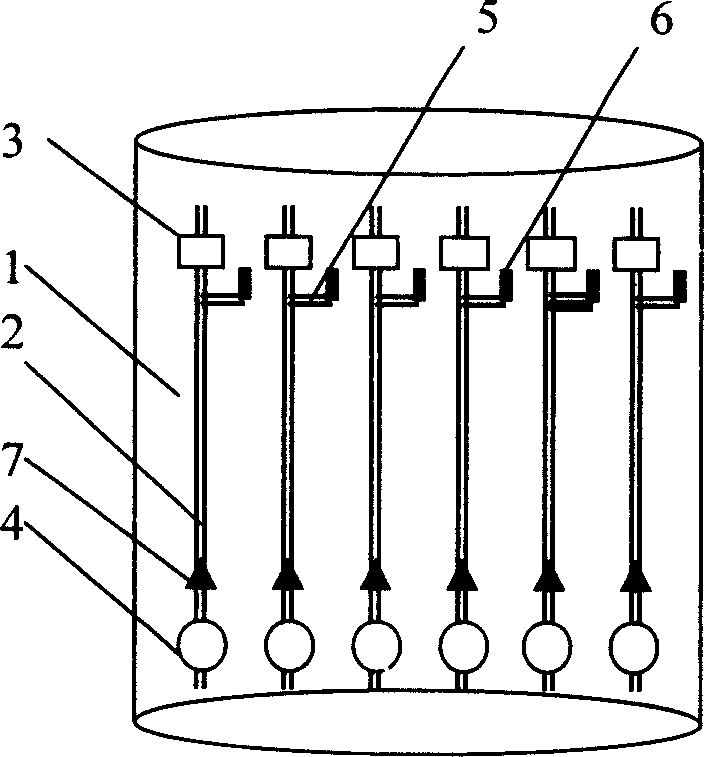

[0012] exist figure 1 Among them, a flow meter (4) is installed at the inlet of each water pipe (2). The flow meter (4) can be a flow switch or a water meter. Speaker bar, light-emitting diode, etc.; manually close the water pipe (2) outlet main valve (3), manually time and interpret the flow meter (4), and determine the degree of water leakage.

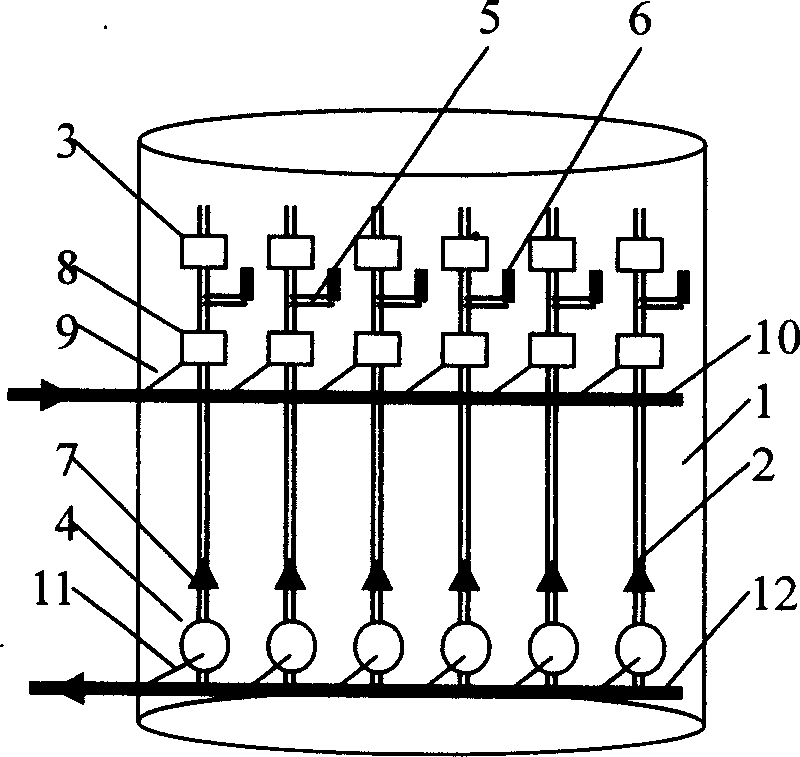

[0013] exist figure 2 Among them, a flow meter (4) is installed at the inlet of each water pipe (2), an electromagnetic valve (7) is installed under the main valve (3) at the outlet of each water pipe, and a certain water pipe is closed by a wire (8) controlled by an automatic instrument. After the electromagnetic valve of the pipe inlet, the output of the flow meter (4) at the inlet of the pipe is transmitted to the detection instrument through the flow meter cable (11), so that automatic continuous inspection can be realized.

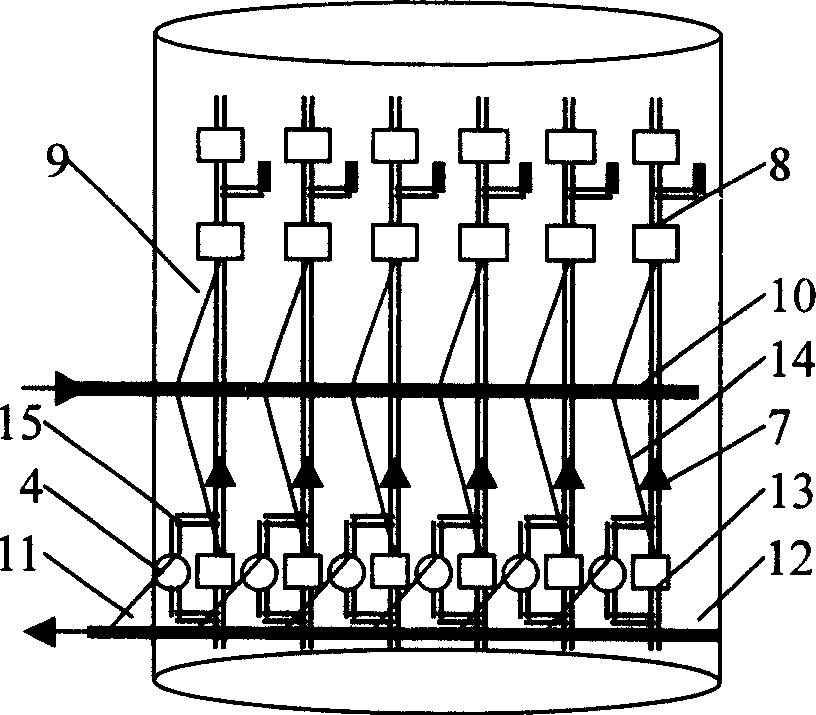

[0014] exist image 3 Among them, solenoid valves (7) and (12) are respectively installed at the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com